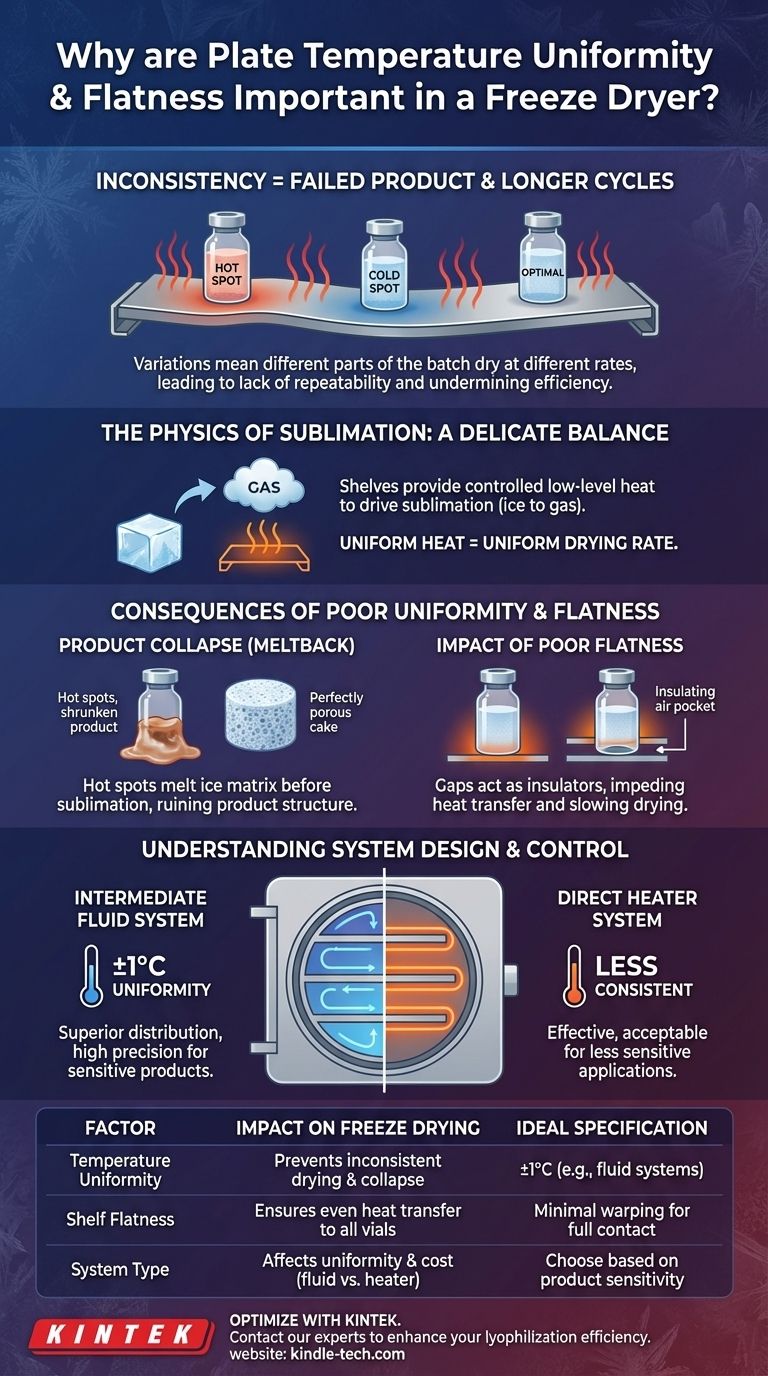

In freeze drying, shelf temperature uniformity and flatness are critical because they directly dictate the consistency and quality of your final product. Variations in temperature across or between shelves mean that different parts of your batch dry at different rates. This inconsistency can lead to failed products, longer processing times, and a lack of repeatability, undermining the core benefits of the lyophilization process.

The primary goal of freeze drying is to gently remove water from a frozen product through sublimation. Because this process is driven by heat energy supplied by the shelves, any non-uniformity in temperature directly translates to non-uniform drying, putting product quality and process efficiency at risk.

The Physics of Sublimation: A Delicate Balance

Freeze drying, or lyophilization, is a sophisticated process that relies on precise control over temperature and pressure. Understanding how shelf temperature fits into this process reveals why its consistency is non-negotiable.

The Role of Shelf Temperature in Sublimation

The core of freeze drying is sublimation, the process where a solid (ice) turns directly into a gas (water vapor) without first melting into a liquid.

The shelves in a freeze dryer do not "freeze" the product. Instead, during the primary drying phase, they provide carefully controlled, low-level heat. This thermal energy is what gives the ice molecules the energy they need to sublimate.

Why Uniformity is Paramount

The rate of sublimation is directly proportional to the amount of heat energy the product receives. If one vial on a shelf receives more heat than another, its ice will sublimate faster.

This creates a significant control problem. The process must be slow enough to protect the coldest product on the shelf but efficient enough to complete in a reasonable time. Uniform temperature ensures every vial proceeds through the drying cycle at the same predictable rate.

Consequences of Poor Uniformity and Flatness

When shelf temperature is inconsistent, or when shelves are not perfectly flat, the entire process is compromised. The consequences range from inefficiency to catastrophic product failure.

Inconsistent Drying and Extended Cycles

The most immediate result of poor temperature uniformity is inconsistent drying. Some vials will finish drying long before others.

Since the entire batch cycle cannot end until the last, slowest-drying vial is complete, the process must be extended. This increases energy consumption, reduces equipment throughput, and raises operational costs.

Risk of Product Collapse (Meltback)

The most severe consequence is product collapse. If a "hot spot" on a shelf heats a vial above its critical collapse temperature, the product's ice matrix will melt before it can sublimate.

This results in a loss of the finely structured, porous cake, leading to a shrunken, gummy, or crystalline product that has lost its quality, cannot be easily reconstituted, and is often unsalvageable.

The Impact of Poor Flatness

Shelf flatness is just as important as temperature uniformity. A warped or uneven shelf will not make perfect contact with the bottom of every vial or tray.

These microscopic gaps act as insulators, severely impeding heat transfer. A vial sitting over a gap will be colder and dry much slower than a vial with full contact, creating the same problems as poor temperature uniformity.

Understanding the Trade-offs: System Design and Control

Not all freeze dryers are built the same. The method used to heat and cool the shelves has a direct impact on the level of uniformity you can achieve.

Intermediate Fluid vs. Direct Heater Systems

Intermediate fluid systems circulate a thermal fluid (like silicone oil) through channels within the shelves. This method provides superior temperature distribution, often achieving uniformity of ±1°C within a single shelf.

Heater-type systems rely on electric heating elements bonded to the shelves. While effective and often less expensive, they can be slightly less consistent than fluid systems but are still perfectly acceptable for many food and medical applications.

The Connection to Vacuum

Vacuum level and temperature are intrinsically linked. The vacuum controls the boiling point of water and aids in pulling water vapor to the cold trap. However, a very high vacuum (low pressure) also acts as an insulator, reducing heat transfer.

If your shelf temperature is already inconsistent, it becomes nearly impossible to maintain the optimal vacuum level that balances efficient heat transfer with vapor removal.

Making the Right Choice for Your Application

Choosing the right level of precision depends entirely on your product's sensitivity and your operational goals.

- If your primary focus is high-value pharmaceuticals or biologicals: Prioritize a system with superior uniformity (e.g., intermediate fluid) to guarantee product integrity and batch-to-batch consistency.

- If your primary focus is general food preservation or less sensitive materials: A standard heater-type system is often sufficient, but you must still verify its uniformity specifications to ensure reliable results.

- If your primary focus is optimizing cycle time and throughput: Tighter temperature uniformity is essential, as it allows you to run more aggressive drying cycles without risking product collapse in isolated hot spots.

Ultimately, investing in shelf uniformity and flatness is an investment in the reliability and success of your entire freeze-drying process.

Summary Table:

| Factor | Impact on Freeze Drying | Ideal Specification |

|---|---|---|

| Temperature Uniformity | Prevents inconsistent drying and product collapse | ±1°C (e.g., intermediate fluid systems) |

| Shelf Flatness | Ensures even heat transfer to all vials/trays | Minimal warping for full contact |

| System Type | Affects uniformity and cost (fluid vs. heater systems) | Choose based on product sensitivity |

Optimize your freeze-drying process with KINTEK's precision lab equipment. Inconsistent shelf temperature or flatness can lead to failed batches, extended cycles, and product collapse. KINTEK specializes in reliable freeze dryers and consumables designed for laboratories that demand repeatable, high-quality results. Contact our experts today to discuss how our solutions can enhance your lyophilization efficiency and protect your valuable products.

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What happens during the freezing phase of lyophilization? Master the Critical First Step for Product Integrity

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- What is cool grinding technology? Unlock Efficient Milling for Heat-Sensitive Materials

- How are the shelves inside an Ultra Freezer designed to maintain temperature uniformity? Ensuring Sample Integrity with Compartmentalized Shelves

- What are the different sterilization methods for a microbiology lab? Ensure Reliable and Safe Experiments