In the world of sensitive experiments, a freeze dryer, or lyophilizer, is essential because it is the only common method that removes water from a sample without destroying its fundamental structure or biological function. It achieves this by transforming delicate liquid or solid samples into a stable, lightweight powder, preserving their integrity for long-term storage, transport, and analysis.

The core problem in sample preservation is that traditional drying uses heat, which denatures proteins, collapses structures, and destroys biological activity. Freeze-drying masterfully sidesteps this by using a low-temperature, high-vacuum process called sublimation, which turns frozen water directly into vapor, gently preserving the sample’s original properties.

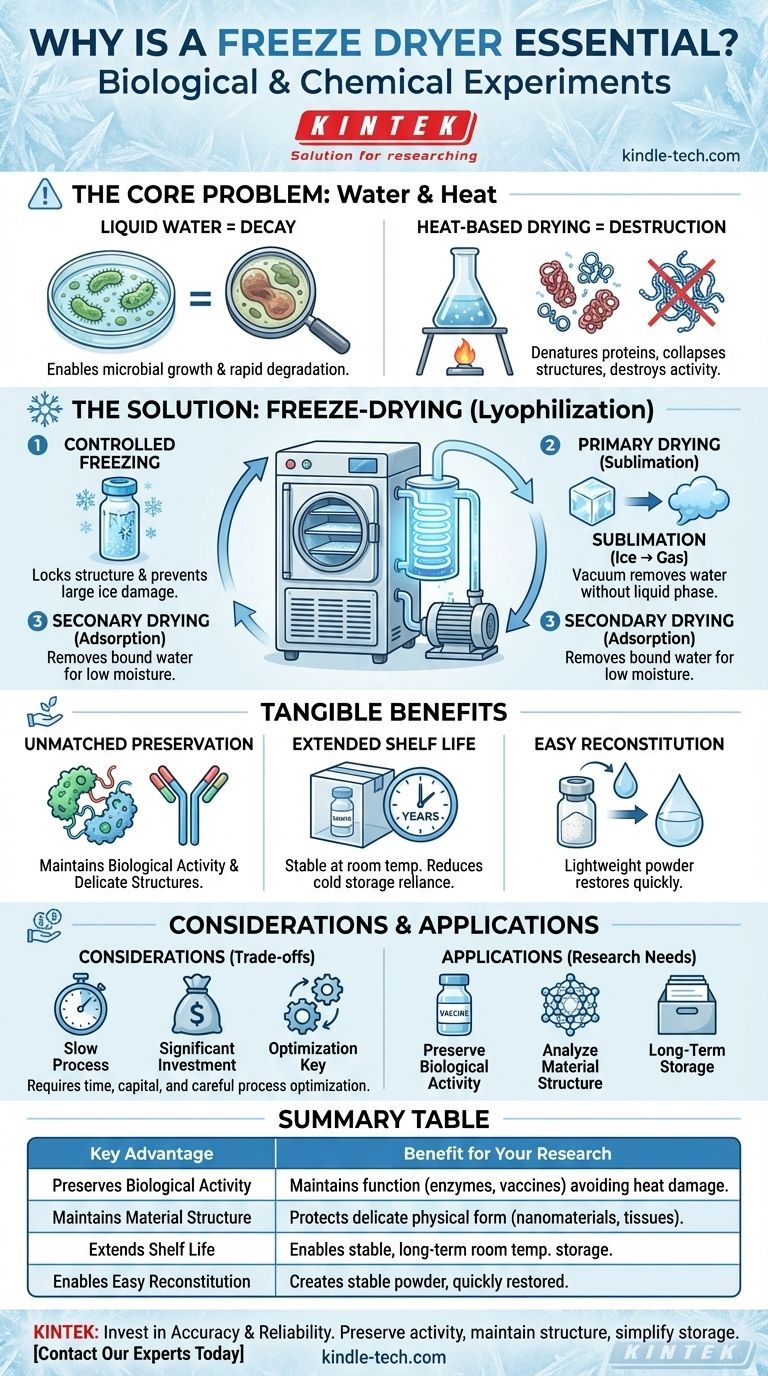

The Core Problem: Why Water Is Both Essential and Destructive

To understand the value of freeze-drying, we must first recognize the central challenge of preserving biological and chemical materials.

The Challenge of Liquid Water

Water is the medium of life, but it is also the medium of decay. The presence of water enables enzymatic reactions and microbial growth, leading to rapid degradation of a sample at room temperature.

The Destructive Nature of Heat-Based Drying

The simplest way to remove water is evaporation using heat. However, for sensitive materials like proteins, vaccines, or advanced nanomaterials, heat is catastrophic. It causes irreversible damage by denaturing molecules and collapsing the intricate microstructures you are trying to study.

How Freeze-Drying Works: The Principle of Sublimation

A freeze dryer doesn't boil water away; it persuades it to leave without disturbing the sample. This is accomplished through a precise, three-stage process.

Step 1: Controlled Freezing

The first step is to freeze the material completely. This is done in a controlled manner to lock the sample’s molecules and overall structure in place, preventing the formation of large ice crystals that could cause physical damage.

Step 2: Primary Drying (Sublimation)

This is the heart of the process. The chamber's pressure is lowered to a near-perfect vacuum. Under these conditions, ice is no longer stable and undergoes sublimation—it transforms directly from a solid (ice) into a gas (water vapor), bypassing the liquid phase entirely. This vapor is then collected on an extremely cold condenser surface, permanently removing it from the chamber.

Step 3: Secondary Drying (Adsorption)

After the bulk of the ice is sublimated, a small amount of water molecules remains bound to the surface of the material. The temperature is raised slightly (while still under vacuum) to give these molecules enough energy to break free, resulting in a final product with exceptionally low moisture content.

The Tangible Benefits in the Laboratory

This elegant process delivers three critical advantages that are indispensable for modern research.

Unmatched Preservation of Integrity

By avoiding the destructive liquid phase and high temperatures, freeze-drying maintains the biological activity of samples like enzymes, antibodies, and vaccines. It also preserves the delicate physical structure of chemical products like graphene or pharmaceutical compounds.

Dramatically Extended Shelf Life

Removing water effectively halts most biological and chemical degradation pathways. A lyophilized sample can often be stored for years at room temperature, eliminating the cost, logistics, and failure risk associated with ultra-low temperature freezers.

Convenience and Reconstitution

The end result is a lightweight, porous powder. This makes samples easy to transport, store, and measure with high precision. When needed, the sample can be quickly restored to its original state by simply adding the appropriate solvent, a process called reconstitution.

Understanding the Trade-offs and Considerations

While essential, freeze-drying is a specialized technique with its own set of practical limitations.

It Is a Slow and Energy-Intensive Process

Freeze-drying is not a rapid method. Depending on the sample volume and composition, a single cycle can take anywhere from several hours to multiple days to complete, consuming significant energy.

Equipment Is a Significant Investment

A laboratory freeze dryer is complex machinery, comprising a refrigeration system, a high-performance vacuum pump, and sophisticated controls. This represents a considerable capital investment and requires regular maintenance to function reliably.

Optimization Is Key

Freeze-drying is not a "one-size-fits-all" solution. The freezing rate, vacuum level, and temperature profile must be carefully optimized for each specific type of sample to prevent product collapse or incomplete drying.

Applying This to Your Research Needs

Your decision to use a freeze dryer should be guided by the non-negotiable requirements of your sample.

- If your primary focus is preserving biological activity (e.g., enzymes, vaccines, or serum): Freeze-drying is essential, as heat-based methods would destroy the very function you need to preserve.

- If your primary focus is analyzing material structure (e.g., nanoparticles, polymers, or tissues): The process is critical for creating a dry sample that maintains its original porosity and form for imaging or analysis.

- If your primary focus is long-term storage and stability of sensitive compounds: Lyophilization is the gold standard for creating archival samples that remain viable for years without specialized cold storage.

Ultimately, a freeze dryer is more than just a drying machine; it is a foundational tool for ensuring the accuracy, reliability, and longevity of scientific work.

Summary Table:

| Key Advantage | Benefit for Your Research |

|---|---|

| Preserves Biological Activity | Maintains the function of enzymes, antibodies, and vaccines by avoiding heat damage. |

| Maintains Material Structure | Protects the delicate physical form of nanomaterials, polymers, and tissues. |

| Extends Shelf Life | Enables stable, long-term storage at room temperature, reducing reliance on ultra-low freezers. |

| Enables Easy Reconstitution | Creates a stable powder that can be quickly restored to its original state with a solvent. |

Ready to enhance the integrity and longevity of your sensitive samples?

A freeze dryer from KINTEK is more than just equipment; it's an investment in the accuracy and reliability of your scientific work. We specialize in providing high-quality lab equipment and consumables tailored to the precise needs of biological and chemical laboratories.

Let us help you:

- Preserve critical biological activity in your enzymes, vaccines, and cell cultures.

- Maintain the intricate structure of your nanomaterials and chemical compounds.

- Simplify long-term storage and ensure sample stability for years to come.

Contact our experts today to find the perfect freeze-drying solution for your laboratory's unique requirements.

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- Why are plate temperature uniformity and flatness important in a freeze dryer? Ensure Product Quality and Process Efficiency

- What happens during the freezing phase of lyophilization? Master the Critical First Step for Product Integrity

- What is cool grinding technology? Unlock Efficient Milling for Heat-Sensitive Materials

- What is the cryogenic grinding process? Achieve Superior Quality and Efficiency for Sensitive Materials

- What is cryogenic grinding of cardamom? Preserve Flavor, Aroma & Color with Extreme Cold