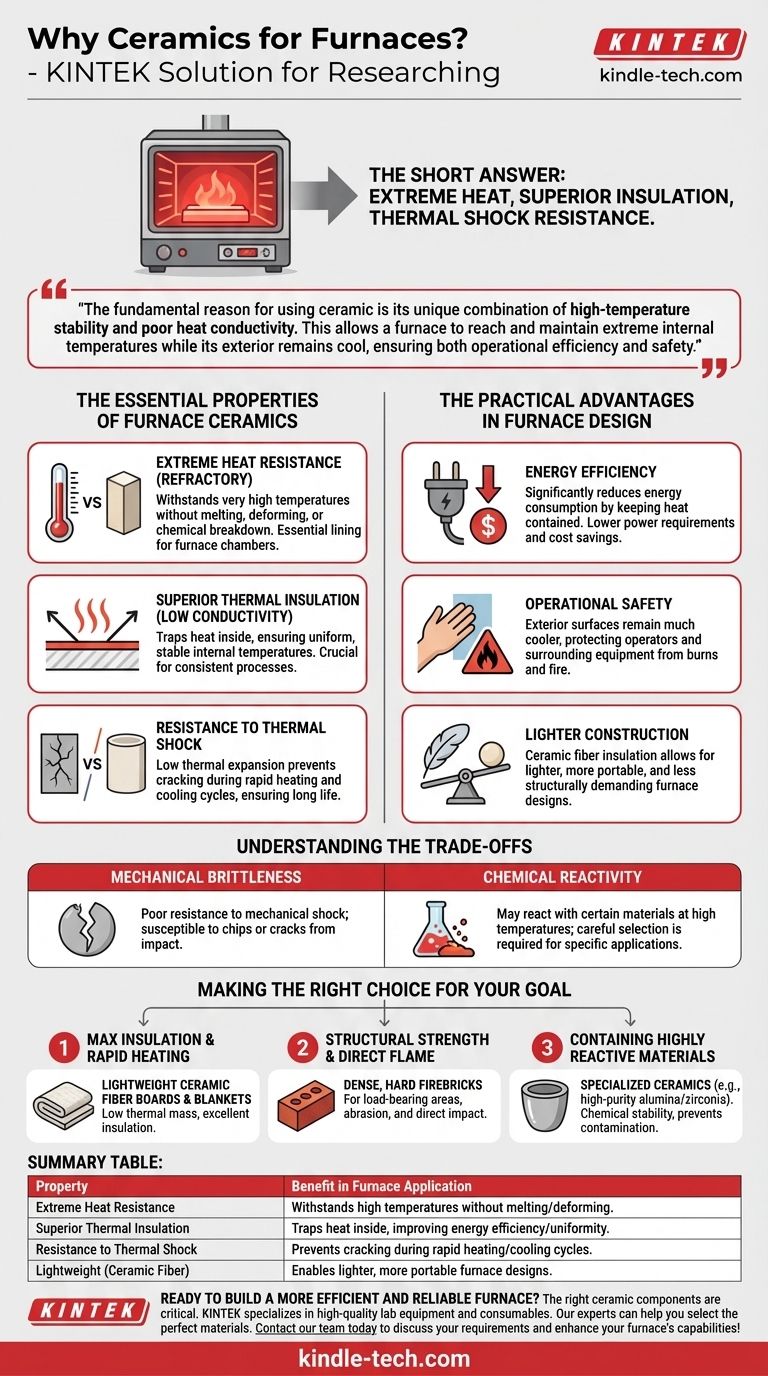

The short answer is that ceramic is used in furnaces for its exceptional ability to resist extreme heat, act as a superior thermal insulator, and withstand rapid temperature changes. These properties allow a furnace to operate efficiently, safely, and reliably at the high temperatures required for industrial and laboratory processes.

The fundamental reason for using ceramic is its unique combination of high-temperature stability and poor heat conductivity. This allows a furnace to reach and maintain extreme internal temperatures while its exterior remains cool, ensuring both operational efficiency and safety.

The Essential Properties of Furnace Ceramics

To understand why ceramic is the material of choice, we need to look beyond a single attribute and see how several key properties work together in a high-temperature environment.

Extreme Heat Resistance

The most fundamental property of furnace ceramics is that they are refractory. This means they can withstand very high temperatures without melting, deforming, or breaking down chemically.

While metals might soften or oxidize, ceramics maintain their structural integrity, making them the essential lining for the furnace chamber.

Superior Thermal Insulation

Heat resistance is not the same as insulation. A material can resist heat but still transfer it readily. Ceramics, particularly ceramic fiber, are excellent thermal insulators.

This low thermal conductivity is crucial for trapping heat inside the furnace. This ensures the internal temperature remains uniform and stable, which is critical for consistent results in processes like heat treating or firing pottery.

Resistance to Thermal Shock

Furnaces are not static environments; they undergo rapid and repeated heating and cooling cycles. This creates immense physical stress on materials.

Ceramics are engineered to have very low thermal expansion, meaning they do not expand or contract much when their temperature changes. This resistance to thermal shock prevents the material from cracking or failing, ensuring a long operational life.

The Practical Advantages in Furnace Design

These core material properties translate directly into tangible benefits that are critical for modern furnace operation.

Energy Efficiency

By effectively keeping heat contained within the furnace, ceramic insulation drastically reduces energy consumption. Less heat escaping to the environment means less power is required to maintain the target temperature, leading to significant cost savings.

Operational Safety

A well-insulated furnace is much cooler on its external surfaces. This is a critical safety feature, protecting operators from burns and reducing the risk of fire to surrounding equipment.

Lighter Construction

Modern ceramic fiber insulation is incredibly lightweight compared to traditional dense firebricks. This allows for the construction of lighter, more portable, or less structurally demanding furnaces without sacrificing performance.

Understanding the Trade-offs

No material is perfect, and ceramics have specific limitations that must be considered in furnace design.

Mechanical Brittleness

While highly resistant to thermal stress, most ceramics are brittle and have poor resistance to mechanical shock. An accidental impact from a tool or a heavy part can easily cause a chip or crack in a ceramic lining.

Chemical Reactivity

Certain ceramics can react with specific materials at very high temperatures. For specialized applications, like melting certain metals or glasses, the specific chemical compatibility of the ceramic lining must be carefully chosen to avoid corrosion and contamination.

Material Selection is Key

The term "ceramic" covers a vast range of materials. A lightweight ceramic fiber blanket is used for pure insulation, while dense, hard refractory bricks are used for structural elements like the furnace floor, where both heat and physical loads must be supported.

Making the Right Choice for Your Goal

The specific type of ceramic used is dictated entirely by its role within the furnace and the process requirements.

- If your primary focus is maximum insulation and rapid heating: Lightweight ceramic fiber boards and blankets are the ideal choice due to their low thermal mass and excellent insulating properties.

- If your primary focus is structural strength and direct flame exposure: Dense, hard firebricks are necessary for load-bearing areas or surfaces that must withstand abrasion and direct impact.

- If your primary focus is containing highly reactive materials: Specialized ceramics like high-purity alumina or zirconia are required to ensure chemical stability and prevent contamination of the melt.

Ultimately, the choice of ceramic is a strategic engineering decision that directly dictates a furnace's efficiency, longevity, and performance.

Summary Table:

| Property | Benefit in Furnace Application |

|---|---|

| Extreme Heat Resistance | Withstands high temperatures without melting or deforming. |

| Superior Thermal Insulation | Traps heat inside, improving energy efficiency and temperature uniformity. |

| Resistance to Thermal Shock | Prevents cracking during rapid heating/cooling cycles, ensuring longevity. |

| Lightweight (Ceramic Fiber) | Enables lighter, more portable furnace designs. |

Ready to build a more efficient and reliable furnace? The right ceramic components are critical for performance and safety. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of furnace ceramics tailored for laboratory and industrial needs. Our experts can help you select the perfect materials for maximum heat resistance, insulation, and longevity.

Contact our team today to discuss your specific requirements and discover how KINTEK can enhance your furnace's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the minimum temperature for a muffle furnace? Understanding Its High-Tech Design

- What role does a high-temperature muffle furnace play in thermal stability testing? Study Nb-22.5Cr-5Si Alloy Resilience

- What role does a high-temperature muffle furnace play in TiO2/CuxOy nanotubes? Achieve Superior Phase Transformation

- What is the application of sintering in powder metallurgy? Transform Powder into Strong, Complex Parts

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- What is the use of muffle furnace in food industry? Essential for Accurate Food Ash Analysis

- What is the function of a high-temperature box furnace in BZY20 synthesis? Optimize Perovskite Phase Purity

- What are the factors that affect sintering? Master the Levers for Dense, Strong Parts