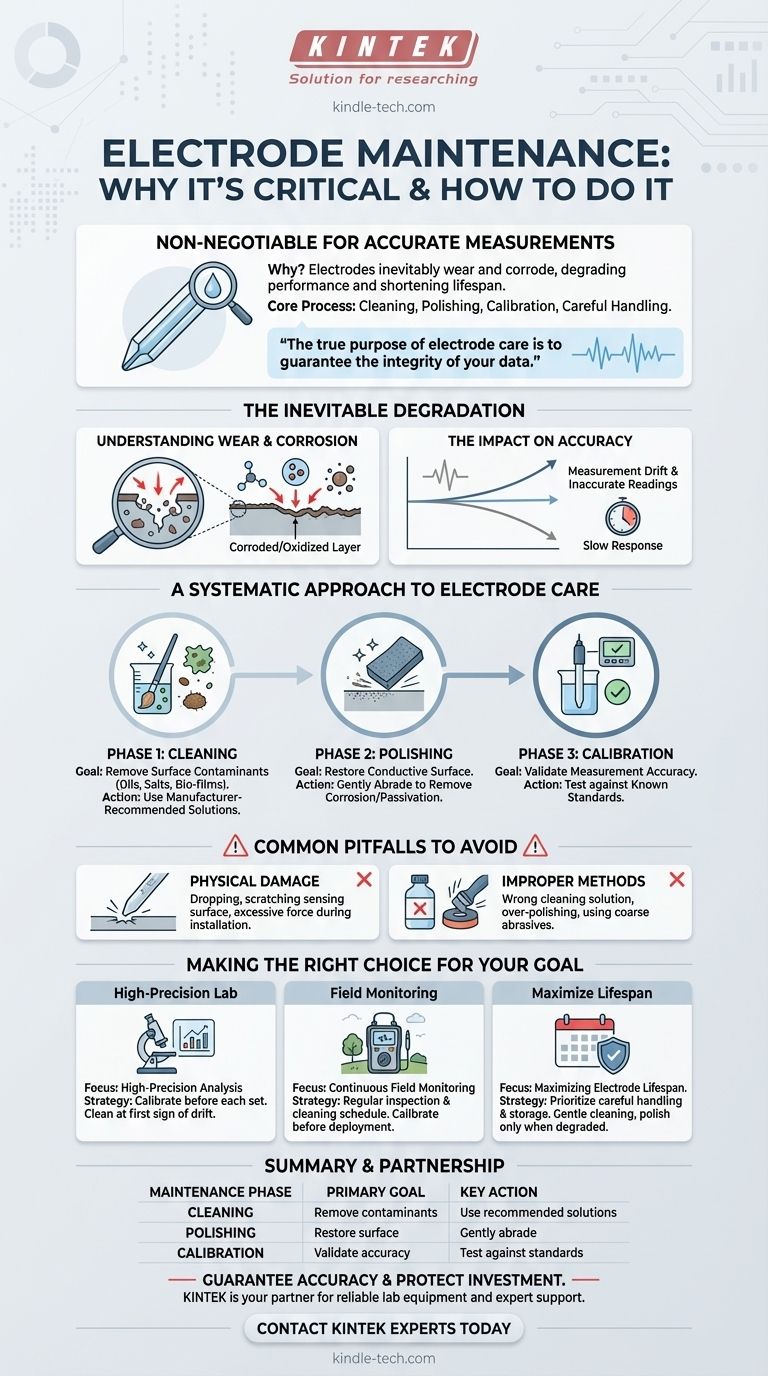

Proper electrode maintenance is non-negotiable for anyone relying on accurate measurements. It is critical because electrodes inevitably wear down and corrode with use, which degrades their performance and shortens their lifespan. The core maintenance process involves a cycle of cleaning, polishing, and calibration, coupled with careful handling to prevent physical damage.

The true purpose of electrode care is not merely to preserve the hardware, but to guarantee the integrity of your data. Viewing maintenance as an integral part of the measurement process itself is the key to achieving reliable results and maximizing the return on your equipment investment.

The Inevitable Degradation of Electrodes

To properly care for an electrode, you must first understand why it fails. An electrode is not a passive observer; it is an active component in a chemical or electrical system.

Understanding Wear and Corrosion

Every time an electrode is used, it participates in electrochemical reactions. This process, combined with potential physical abrasion from the sample medium, causes microscopic bits of its surface to wear away.

Over time, this material loss accumulates. Furthermore, exposure to air and reactive chemicals causes the electrode's surface to oxidize or corrode, forming a less conductive layer.

The Impact on Accuracy

This degradation directly impacts measurement accuracy. A corroded or contaminated surface alters the electrode's electrical properties and slows its response time.

This leads to measurement drift, inaccurate readings, and a general loss of signal sensitivity. Without maintenance, your data becomes unreliable.

A Systematic Approach to Electrode Care

A consistent maintenance protocol is the most effective way to counteract degradation. This process can be broken down into three distinct phases.

Phase 1: Cleaning

The first step is always cleaning. This process is designed to remove loose surface contaminants like oils, precipitated salts, or biological films.

Cleaning addresses issues that are purely on the surface and ensures you are evaluating the true condition of the electrode before taking more aggressive steps.

Phase 2: Polishing

Polishing is a corrective action used when simple cleaning is not enough. Its purpose is to physically remove the top layer of the electrode material that has become corroded or passivated.

This process exposes a fresh, smooth, and highly conductive surface, restoring the electrode's original performance characteristics.

Phase 3: Calibration

Calibration is the final validation step. After cleaning and polishing, the electrode must be tested against a known standard to verify that it is reading accurately.

If an electrode cannot hold a stable calibration after proper maintenance, it is a strong indicator that it has reached the end of its operational life and needs to be replaced.

Common Pitfalls to Avoid

Effective maintenance is as much about avoiding bad practices as it is about following good ones. Mishandling is a primary cause of premature failure.

Physical Damage

Electrodes are often sensitive instruments. Dropping them, scratching the sensing surface, or applying excessive force during installation can cause irreparable damage.

Always handle electrodes with care, especially during installation and removal from their housing or probe.

Improper Cleaning or Polishing

Using the wrong cleaning solution can chemically damage the electrode. Likewise, over-polishing or using an abrasive that is too coarse can wear down the electrode material far too quickly.

Follow the manufacturer's recommendations for cleaning agents and polishing materials to avoid causing more harm than good.

Making the Right Choice for Your Goal

Your maintenance strategy should be adapted to your specific application and accuracy requirements.

- If your primary focus is high-precision laboratory analysis: Calibrate before each set of measurements and clean at the first sign of signal drift to ensure maximum data integrity.

- If your primary focus is continuous field monitoring: Implement a regular schedule for inspection and cleaning, and always calibrate before deployment to ensure long-term reliability.

- If your primary focus is maximizing electrode lifespan: Prioritize careful handling and proper storage, performing gentle cleaning regularly and reserving polishing only for when performance noticeably degrades.

Ultimately, a well-maintained electrode is the foundation of trustworthy and repeatable results.

Summary Table:

| Maintenance Phase | Primary Goal | Key Action |

|---|---|---|

| Cleaning | Remove surface contaminants | Use manufacturer-recommended solutions |

| Polishing | Restore conductive surface | Gently abrade to remove corrosion |

| Calibration | Validate measurement accuracy | Test against known standards |

Guarantee the accuracy of your measurements and protect your investment in lab equipment. Proper electrode care is fundamental to reliable data, and KINTEK is your partner in achieving this. We specialize in high-quality lab equipment and consumables, providing the reliable tools and expert support your laboratory needs to maintain peak performance.

Contact our experts today to discuss your specific application and ensure your electrodes deliver precise, repeatable results.

Visual Guide

Related Products

- Side Window Optical Electrolytic Electrochemical Cell

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Li-Air Battery Case for Battery Lab Applications

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

People Also Ask

- What optical features does the H-type electrolytic cell have? Precision Quartz Windows for Photoelectrochemistry

- Why are diaphragm-type electrolytic cells preferred in iron electrowinning? Boost Efficiency and Prevent Re-dissolution

- Why is it necessary for electrochemical cells to have quartz windows? Ensure UV Transmission for Accurate Measurements

- What are the benefits of using a transparent electrolytic cell for OCP? Visual Monitoring of Corrosion in Real-Time

- What is the function of a transparent acrylic electrolytic cell? Optimize Variable-Gap Electrolysis Research