In short, a heating element's resistance must be high to efficiently convert electrical energy into heat. A low-resistance material would allow electricity to pass through too easily, generating very little heat, or it would require a dangerously high current to have the same effect. High resistance acts as a bottleneck, forcing the energy from the flowing electric current to be released as heat.

The core principle is that electrical resistance creates a form of "friction" for flowing electrons. By intentionally using a high-resistance material, a heating element maximizes this friction, effectively transforming electrical energy into a controlled, significant amount of thermal energy.

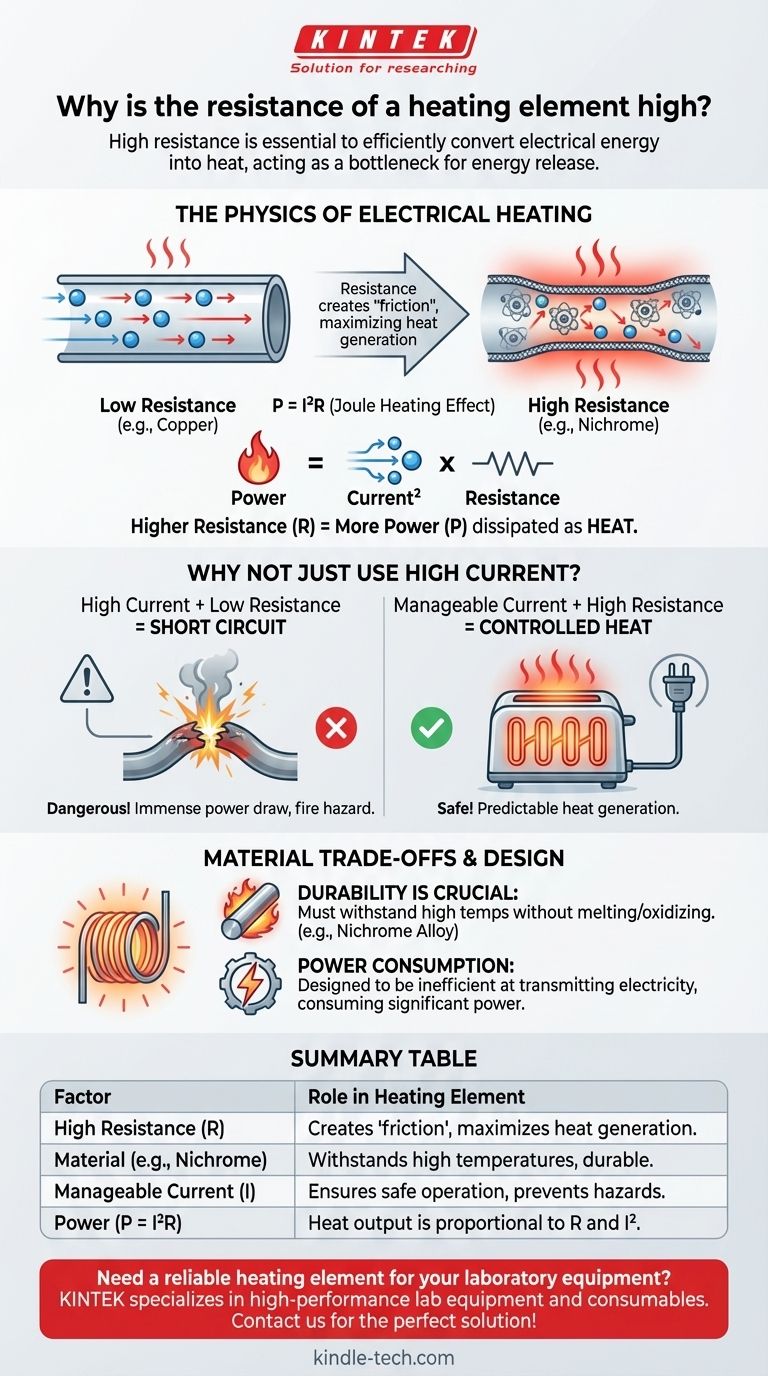

The Physics of Electrical Heating

To understand why high resistance is essential, we must first look at how electricity generates heat. The entire process is governed by a fundamental relationship between current, resistance, and power.

The Flow of Electrical Current

An electric current is simply the movement of electrons through a material. These electrons carry electrical energy, which we want to convert into a different form—in this case, heat.

Resistance as Electrical "Friction"

As electrons flow through a material, they collide with the atoms of that material. Resistance is the measure of how much a material opposes or restricts this flow of electrons.

A material with low resistance, like copper, allows electrons to pass through with very few collisions. A material with high resistance, like the nichrome wire in a toaster, causes many more collisions.

The Joule Heating Effect (I²R)

Each collision between an electron and an atom transfers energy, causing the atom to vibrate more intensely. This increased atomic vibration is what we perceive as heat.

This phenomenon is described by the Joule heating effect, where the power (P) converted into heat is equal to the current (I) squared, multiplied by the resistance (R): P = I²R. This formula makes it clear that a higher resistance (R) directly results in more power being dissipated as heat for a given current.

Why Not Just Use High Current?

Looking at the formula P = I²R, it might seem that you could generate heat just as easily by using a very high current (I) with a low-resistance wire. However, this approach is both impractical and dangerous.

The Problem with Low Resistance

A circuit with very low resistance and very high current is essentially a short circuit. This would draw an immense amount of power from the source, causing the power supply to fail or, more likely, melting the wires themselves and creating a significant fire hazard.

The Goal of Controlled Heat Generation

The purpose of a heating element is to generate and contain heat in a specific, predictable, and safe location. A high-resistance element allows for substantial heat generation using a manageable and safe level of current. This is the key to designing functional appliances like electric stoves, space heaters, and toasters.

Understanding the Trade-offs

Choosing a material for a heating element isn't just about finding the highest resistance possible. There are critical trade-offs involved in designing a safe and effective component.

Material Durability is Crucial

The material must not only have high resistance but also be able to withstand extremely high temperatures without melting, degrading, or oxidizing (rusting) too quickly. This is why specialized alloys like Nichrome (nickel-chromium) are commonly used.

Power Consumption by Design

By definition, a heating element is designed to be inefficient at transmitting electricity. Its job is to lose electrical energy as heat. This means that all heating appliances are high-power devices, consuming a significant amount of electricity to perform their function.

Making the Right Choice for Your Goal

Understanding the role of resistance allows you to see it not as a flaw, but as a fundamental tool for controlling electrical energy. Your goal determines whether resistance should be high or low.

- If your primary focus is efficient power transmission: You must use a low-resistance material like copper to minimize energy loss as heat.

- If your primary focus is generating controlled heat: You must use a high-resistance material like nichrome to maximize the conversion of electrical energy into thermal energy.

- If your primary focus is safety: You use resistance strategically, as seen in fuses that use a low-melting-point wire to purposefully break a circuit when current (and therefore heat) becomes dangerously high.

Ultimately, high resistance is a deliberate design choice that enables the precise and safe conversion of electricity into the heat that powers countless modern devices.

Summary Table:

| Factor | Role in Heating Element |

|---|---|

| High Resistance (R) | Creates 'friction' for electrons, maximizing heat generation (Joule Heating). |

| Material (e.g., Nichrome) | Withstands high temperatures without melting or degrading quickly. |

| Manageable Current (I) | Ensures safe operation, preventing short circuits and hazards. |

| Power (P = I²R) | The heat output is directly proportional to the resistance and the square of the current. |

Need a reliable heating element for your laboratory equipment?

At KINTEK, we specialize in high-performance lab equipment and consumables. Our heating elements are engineered for precise temperature control, durability, and safety, ensuring efficient thermal processing for your applications.

Contact us today to find the perfect heating solution for your laboratory needs!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Rotating Platinum Disk Electrode for Electrochemical Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- Is tungsten shock resistant? Uncovering the Surprising Brittleness of a Hard Metal

- What are the high temperature furnace elements to be used in oxidizing environments? Select the Right Element for Your Lab

- What are the factors on which heat produced in a heating element depends? Master Joule's Law for Precise Control

- What role does a specialized ceramic heating holder play during the irradiation process? Achieve Nuclear Precision

- Why is tungsten used in furnaces? Unmatched Heat Resistance for Extreme Temperatures

- How do PTC fan heaters work? Discover Efficient Space Heating Solutions for Labs & Offices

- Why do heating elements have high resistance? To Efficiently Convert Electricity into Heat

- What role do laboratory heaters and thermocouples play in low-temperature nitriding? Achieve Precision Thermal Control