In short, a vacuum is required in Physical Vapor Deposition (PVD) to accomplish two primary objectives. First, it removes atmospheric gases that would otherwise collide with and scatter the vaporized coating material, preventing it from reaching the target. Second, it eliminates contaminants like oxygen and water vapor that would react with the hot vapor and get embedded into the thin film, compromising its purity, structure, and performance.

The core purpose of the vacuum in PVD is not simply to create an empty space, but to engineer a highly controlled environment. This environment ensures that coating particles travel in a straight line from source to substrate and guarantees the final film is chemically pure and structurally sound.

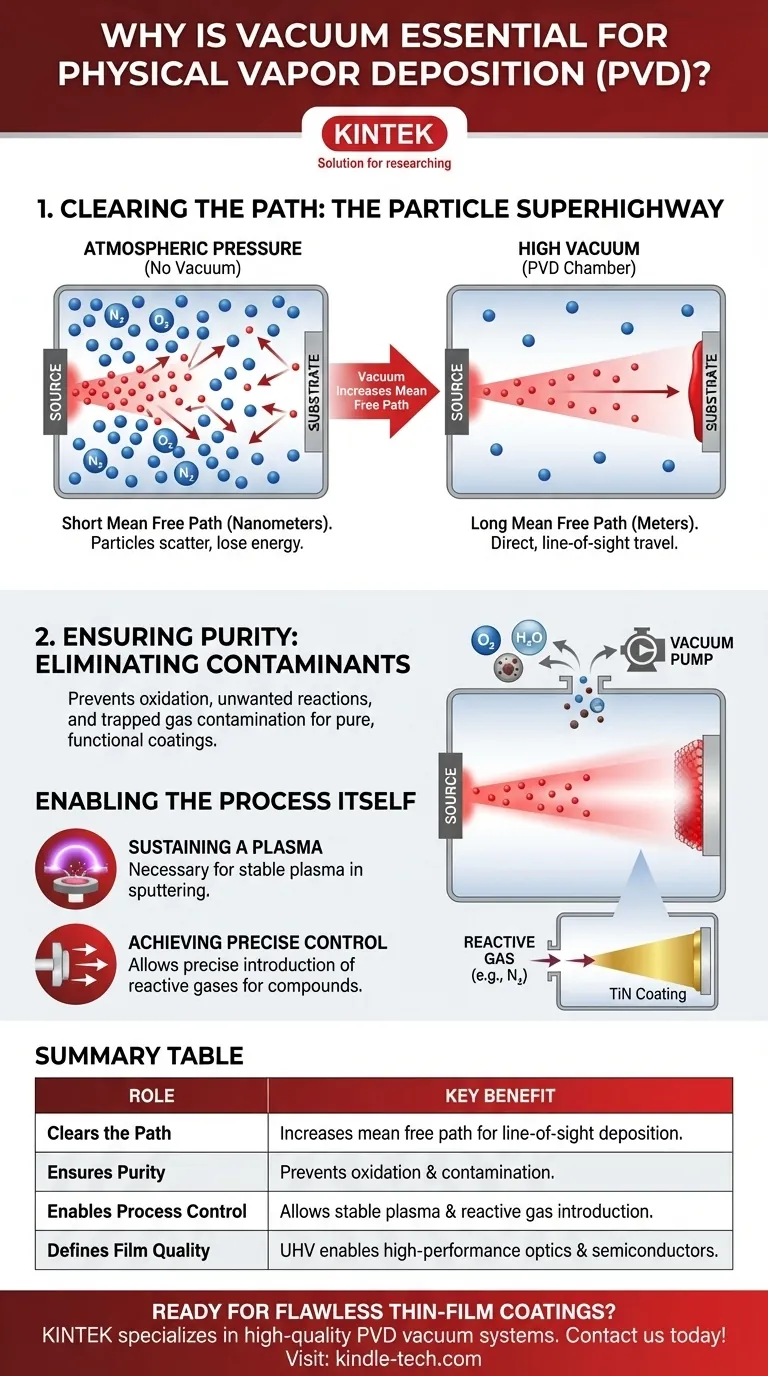

The First Critical Role: Clearing the Path

The primary challenge in any deposition process is getting the coating material from its source to the part you want to coat (the substrate). A vacuum is the only practical way to make this journey possible.

Understanding Mean Free Path

Mean Free Path is the average distance a single particle can travel before it collides with another particle. This concept is central to understanding the need for a vacuum.

At normal atmospheric pressure, the air is incredibly dense with nitrogen, oxygen, and other gas molecules. The mean free path is extremely short—on the scale of nanometers.

The Problem with Atmospheric Pressure

If you tried to vaporize a material in open air, the newly created vapor particles would collide with air molecules almost instantly. They would scatter in random directions, lose their energy, and never reach the substrate with the required directionality or force to form a coherent film.

The Vacuum Solution: A Particle Superhighway

By pumping the air out of a chamber, we drastically reduce the number of gas molecules present. This increases the mean free path from nanometers to meters.

The high vacuum effectively creates a clear, unobstructed "superhighway." This allows the vaporized coating particles to travel in a straight, line-of-sight path directly from the source to the substrate, ensuring an efficient and well-directed deposition process.

The Second Critical Role: Ensuring Purity

The quality of a thin film is defined by its purity. Atmospheric gases are the single greatest threat to creating a pure, functional coating.

Eliminating Unwanted Reactions

The material being vaporized in a PVD process is often at a very high temperature and is therefore highly reactive.

If stray oxygen or water vapor molecules are present in the chamber, they will readily react with the hot metal vapor. This forms unwanted oxides and hydrides within the film, altering its intended electrical, optical, or mechanical properties.

Preventing Atmospheric Contamination

Beyond chemical reactions, atmospheric gases can simply become trapped or embedded within the growing film. This contamination disrupts the crystal structure of the film, creating defects that can compromise its integrity, adhesion, and performance.

Enabling the PVD Process Itself

For many common PVD techniques, the process simply cannot function without a low-pressure environment.

Sustaining a Plasma

Techniques like magnetron sputtering rely on creating a plasma, typically from an inert gas like Argon. This plasma is used to bombard a source material, ejecting atoms that then travel to the substrate.

It is impossible to ignite and sustain a stable, low-energy plasma at atmospheric pressure. The vacuum environment is a fundamental requirement for the physics of the process to work.

Achieving Precise Control

The vacuum allows for total control over the chamber's atmosphere. After removing the air, engineers can backfill the chamber with a specific, high-purity process gas.

This enables reactive sputtering, where a gas like nitrogen is intentionally introduced in precise amounts to react with the sputtered metal, forming a specific compound film like Titanium Nitride (TiN). This level of control is impossible without first creating a clean vacuum.

Understanding the Trade-offs

While essential, creating and maintaining a vacuum introduces its own set of challenges that are important to acknowledge.

Cost and Complexity

High-vacuum systems are complex and expensive. They require a series of pumps (e.g., roughing pumps and high-vacuum turbomolecular or cryogenic pumps), along with sophisticated chambers, seals, and gauges to achieve and maintain the required low pressures.

Process Time and Throughput

A significant portion of any PVD cycle is the "pump-down time"—the time it takes for the pumps to remove the air and reach the target vacuum level. This non-productive time directly impacts the overall throughput and cost-effectiveness of the operation.

Level of Vacuum vs. Film Quality

The "quality" of the vacuum (i.e., how low the pressure is) directly correlates to the potential purity of the film. Achieving an ultra-high vacuum (UHV) results in the purest films but requires significantly more time and more expensive equipment than a standard high-vacuum process.

Matching the Vacuum to Your Goal

The required level of vacuum is dictated entirely by the application and the desired properties of the final film.

- If your primary focus is decorative coatings (e.g., on fixtures): A standard high vacuum is sufficient to ensure good adhesion and prevent major discoloration from oxidation.

- If your primary focus is high-performance optics or semiconductors: An ultra-high vacuum (UHV) is non-negotiable to prevent even trace amounts of contamination that would ruin the device's optical or electrical performance.

- If your primary focus is creating specific compounds (e.g., TiN for tooling): A controlled high vacuum is critical not just for removing contaminants, but for enabling the precise introduction of the required reactive gas.

Ultimately, the vacuum is the foundational element that transforms PVD from a theoretical concept into a precise and reliable manufacturing technology.

Summary Table:

| Role of Vacuum in PVD | Key Benefit |

|---|---|

| Clears the Path | Increases mean free path, enabling line-of-sight deposition from source to substrate |

| Ensures Purity | Prevents oxidation and contamination from gases like oxygen and water vapor |

| Enables Process Control | Allows for stable plasma generation and reactive gas introduction (e.g., for TiN coatings) |

| Defines Film Quality | Ultra-high vacuum (UHV) enables high-performance optics and semiconductors |

Ready to achieve flawless thin-film coatings with precision PVD equipment? KINTEK specializes in high-quality lab equipment and consumables, including vacuum systems tailored for Physical Vapor Deposition. Whether you're working on decorative coatings, tooling enhancements, or advanced semiconductors, our solutions ensure purity, control, and reliability. Contact us today to discuss how we can support your laboratory's specific PVD needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications