The short answer is that Potassium Bromide (KBr) is used because it has two essential properties for infrared (IR) spectroscopy. First, it is transparent to infrared light in the analytical range, meaning it doesn't create interfering signals. Second, under high pressure, it becomes plastic and fuses into a solid, transparent disc, creating a perfect solid-state matrix to hold the sample for analysis.

The core reason for using KBr is its function as an ideal "window" for the sample. It encapsulates a finely ground sample in a solid, IR-transparent medium, allowing the spectrometer's light beam to pass through and measure the sample's unique absorption spectrum without interference from the matrix itself.

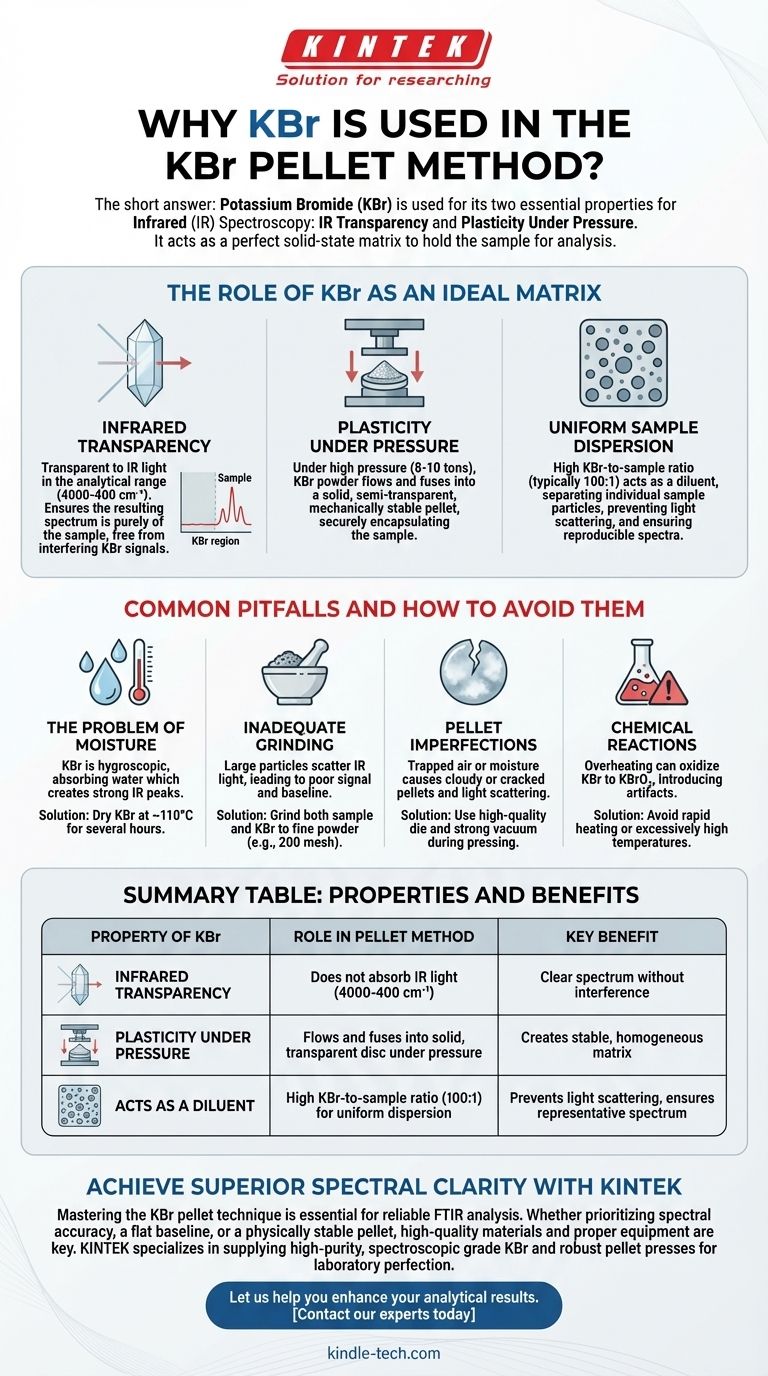

The Role of KBr as an Ideal Matrix

To understand why KBr is the standard, we must look at its specific physical and chemical properties that make it uniquely suited for this technique.

Infrared Transparency

The most critical requirement for a matrix material is that it does not absorb infrared light in the frequency range being measured.

KBr is an alkali halide with a simple ionic bond that does not produce absorption peaks in the mid-infrared region (4000-400 cm⁻¹), which is where most organic and inorganic compounds show their characteristic spectral fingerprints.

This transparency ensures that the resulting spectrum is purely that of the sample, not a combination of the sample and the KBr.

Plastic Deformation Under Pressure

Unlike many crystalline materials that fracture under pressure, alkali halides like KBr exhibit plasticity.

When subjected to high pressure (typically 8-10 tons), the fine KBr powder flows and fuses together, forming a homogenous, semi-transparent pellet that is mechanically stable.

This property allows the sample, which is mixed in, to be held securely and uniformly within the KBr disc.

Uniform Sample Dispersion

The KBr pellet method requires a very small amount of sample, typically in a 100:1 ratio of KBr to sample by weight.

The large volume of KBr powder acts as a diluent, separating the individual sample particles. This uniform dispersion is crucial for preventing light scattering and ensuring that the IR beam interacts with a representative amount of the sample, leading to a high-quality, reproducible spectrum.

Common Pitfalls and How to Avoid Them

While KBr is an ideal material, the quality of the final spectrum is highly dependent on proper technique. Several common issues can compromise results.

The Problem of Moisture

Water (H₂O) has very strong and broad absorption bands in the infrared spectrum. KBr is hygroscopic, meaning it readily absorbs moisture from the atmosphere.

If the KBr is not thoroughly dried, or if it's exposed to humid air, water peaks will appear in the spectrum, potentially obscuring important sample peaks. This is why drying KBr at ~110°C for several hours is a mandatory step.

Inadequate Grinding and Mixing

The clarity of the final pellet and the quality of the spectrum depend on particle size. Both the sample and the KBr must be ground into a very fine powder (e.g., 200 mesh).

If particles are too large, they will scatter the IR light instead of transmitting it. This scattering results in a poor signal-to-noise ratio and a sloping, difficult-to-interpret baseline.

Pellet Imperfections

A cloudy or cracked pellet is a clear sign of a problem. This is often caused by trapped air or moisture due to an inadequate vacuum during the pressing process.

These imperfections also cause significant light scattering, degrading the quality of the final spectrum.

Chemical Reactions

Care must be taken during the drying process. Heating KBr too rapidly or at too high a temperature can cause it to oxidize into potassium bromate (KBrO₃).

This chemical change not only discolors the powder but can also introduce unwanted artifacts into the spectrum.

Making the Right Choice for Your Goal

Achieving a high-quality spectrum with the KBr method requires careful attention to detail. Your primary objective will determine where to focus your efforts.

- If your primary focus is spectral accuracy: Use high-purity, spectroscopic grade KBr and be meticulous about drying it to completely eliminate interfering water peaks.

- If your primary focus is a flat baseline and good signal: Concentrate on grinding both the sample and KBr into the finest possible powder and blending them thoroughly to minimize light scattering.

- If your primary focus is creating a physically stable pellet: Ensure you apply sufficient pressure in a high-quality die under a strong vacuum to remove all trapped air and moisture.

Mastering this technique is a foundational skill that consistently delivers clear and reliable analytical results.

Summary Table:

| Property of KBr | Role in Pellet Method | Key Benefit |

|---|---|---|

| Infrared Transparency | Does not absorb IR light in the analytical range (4000-400 cm⁻¹) | Provides a clear spectrum of the sample without interference |

| Plasticity Under Pressure | Flows and fuses into a solid, transparent disc under high pressure (8-10 tons) | Creates a stable, homogeneous matrix to hold the sample |

| Acts as a Diluent | High KBr-to-sample ratio (typically 100:1) ensures uniform dispersion | Prevents light scattering and ensures a representative spectrum |

Achieve Superior Spectral Clarity with KINTEK

Mastering the KBr pellet technique is essential for reliable FTIR analysis. Whether your priority is spectral accuracy, a flat baseline, or a physically stable pellet, using high-quality materials and proper equipment is key.

KINTEK specializes in supplying high-purity, spectroscopic grade KBr and robust pellet presses designed for laboratory perfection. We serve the precise needs of analytical laboratories, research institutions, and quality control departments.

Let us help you enhance your analytical results. Contact our experts today to find the ideal consumables and equipment for your specific application.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- How can a laboratory hydraulic press be utilized for the cold welding of silver nanowire junctions? Achieve Low Resistance

- What is the difference between mechanical power press and hydraulic press? High-Speed vs. Controlled Force

- How does a laboratory hydraulic press contribute to green bodies for solid-state batteries? Optimize Your Cell Density

- What is the role of a hydraulic pellet press in preparing vanadium-titanium magnetite? Optimize Densification & Reactivity

- Why is a laboratory pressure testing machine essential for nano-carbon-cement? Validate High-Performance Composites

- What is the operating temperature of a standard hydraulic system? Achieve Peak Efficiency and Longevity

- What is the function of a laboratory hydraulic press in C/C-SiC preparation? Achieve Precision CFRP Green Body Densification

- What would happen to a diamond in a hydraulic press? It Shatters Due to Brittleness, Not Lack of Hardness