No, a stable, high-quality CVD diamond will not change color over time. Lab-grown CVD diamonds are atomically identical to natural diamonds, sharing the same physical, thermal, and optical properties. This means their color—or lack thereof—is a permanent, intrinsic characteristic, making them just as resilient and timeless as their mined counterparts.

The color of a CVD diamond is not a coating or a dye; it is a fundamental property determined at the atomic level during its formation. Whether it is created to be perfectly colorless or a vibrant fancy color, its hue is permanent and will not fade.

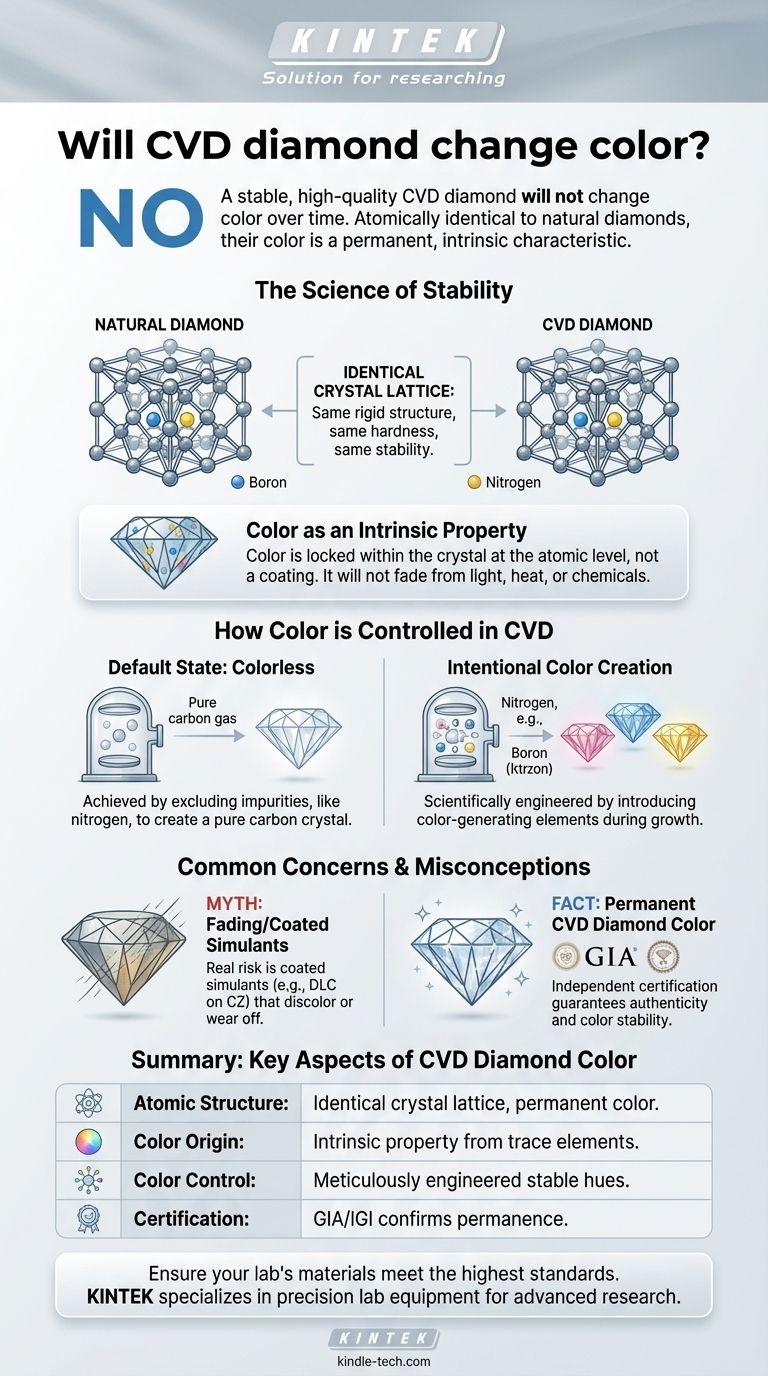

The Science of Diamond Color Stability

To understand why a CVD diamond's color is permanent, we must first understand what a diamond is. The answer lies in its fundamental atomic structure.

An Identical Crystal Lattice

A CVD (Chemical Vapor Deposition) diamond is a real diamond. It is not a simulant like cubic zirconia. It possesses the exact same crystal structure as a mined diamond: a rigid, interlocking lattice of carbon atoms.

This identical structure is what gives a diamond its unparalleled hardness, brilliance, and thermal conductivity. It is also the reason its color is inherently stable.

Color as an Intrinsic Property

A diamond's color is caused by the presence of trace elements or structural anomalies within its carbon lattice. It is not something applied to the surface.

For example, nitrogen atoms trapped during formation cause a yellow hue, while boron atoms create a blue color. These elements are locked within the crystal, and everyday exposure to light, heat, or chemicals will not alter them.

How Color is Controlled in CVD Diamonds

The color of a CVD diamond is a highly controlled and deliberate outcome of the manufacturing process. Scientists can either meticulously exclude impurities to create a colorless stone or introduce specific elements to produce a fancy colored one.

The Default State: Colorless

The goal for most gem-quality CVD production is to create a perfectly colorless diamond. This is achieved by growing the diamond in a vacuum chamber with highly pure carbon-rich gases.

The primary challenge is preventing contamination from nitrogen, which is abundant in our atmosphere and can cause unwanted yellow or brownish tints. Advanced techniques are used to remove or "trap" any stray nitrogen atoms, ensuring a pure carbon crystal.

Intentional Color Creation

To create valuable fancy colored diamonds, scientists intentionally introduce specific, color-generating elements into the gas mixture during the growth process.

By precisely controlling the introduction of elements like nitrogen or boron, or by using post-growth treatments like irradiation, manufacturers can create a spectrum of stable, beautiful pink, blue, and yellow diamonds.

Common Concerns and Misconceptions

The concern about color change often stems from experiences with diamond simulants or coated gems, which are entirely different materials from lab-grown diamonds.

The Myth of Fading

A properly grown CVD diamond will not fade or change color from exposure to sunlight, cleaning, or daily wear. Its color is locked into its atomic structure. Any story of a "diamond" changing color is almost certainly referring to a coated simulant or a gem that was not a diamond in the first place.

Distinguishing from Coated Simulants

The real risk is not that your CVD diamond will change color, but that you might unknowingly purchase a less durable stone, like cubic zirconia, that has been given a thin diamond-like carbon (DLC) coating. These coatings can scratch, wear away, or discolor over time, revealing the different material underneath.

The Importance of Certification

The only way to guarantee the quality and stability of your CVD diamond is through independent certification from a reputable gemological lab like the GIA (Gemological Institute of America) or IGI (International Gemological Institute). A certificate confirms that the stone is a diamond and details its specific properties, including its color grade and origin.

Making the Right Choice for Your Diamond

Understanding the permanence of CVD diamond color allows you to choose with confidence, focusing on quality and authenticity.

- If your primary focus is long-term stability: Rest assured that a certified CVD diamond is as physically and optically permanent as any natural diamond.

- If your primary focus is a fancy color: Know that the color in a lab-grown diamond is an engineered and stable feature, not a temporary treatment.

- If your primary focus is ensuring authenticity: Always insist on a full grading report from a major gemological laboratory to verify the stone's identity and characteristics.

Ultimately, a CVD diamond's color is a permanent testament to the precise and controlled science behind its creation.

Summary Table:

| Key Aspect | Description |

|---|---|

| Atomic Structure | Identical crystal lattice to natural diamonds, ensuring permanent color. |

| Color Origin | Intrinsic property from trace elements (e.g., nitrogen for yellow, boron for blue). |

| Color Control | Meticulously engineered during growth for stable colorless or fancy hues. |

| Certification | GIA or IGI grading confirms color permanence and authenticity. |

Ensure your lab's materials meet the highest standards of quality and permanence.

At KINTEK, we specialize in precision lab equipment and consumables, serving the exacting needs of modern laboratories. Whether you're working with advanced materials like diamonds or other critical samples, our reliable tools support your research with uncompromising accuracy and durability.

Contact our experts today to find the perfect solution for your laboratory requirements and experience the KINTEK difference.

Visual Guide

Related Products

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Optical Windows for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is a diamond machine? Unlock the Power of Diamond Tooling for Your Toughest Materials

- What is the fluorescence of a CVD diamond? A Guide to Its Unique Glow and Purpose

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How do lab-grown diamonds compare to natural diamonds? Uncover the Truth About Origin, Price, and Value

- Do natural diamonds last longer? The Truth About Diamond Durability and Value

- What is the process of lab created diamonds? A Clear Guide to HPHT & CVD Methods

- Are artificial diamonds as strong as natural diamonds? Discover the Truth About Lab-Grown Diamond Durability

- What are the advantages and applications of MPCVD? The Gold Standard for High-Purity Single-Crystal Diamond Growth