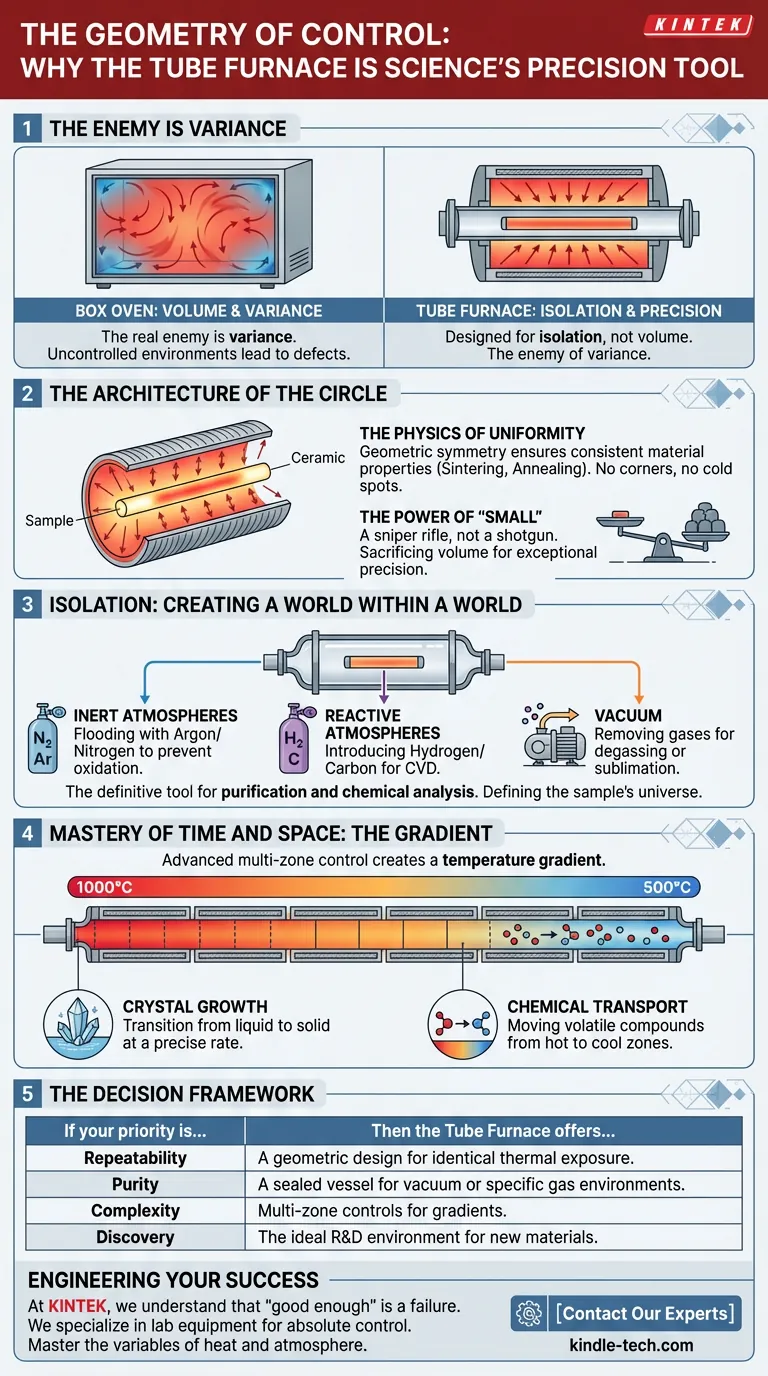

The Enemy is Variance

In the laboratory, the enemy is rarely the inability to generate heat. Fire is easy. Energy is abundant.

The real enemy is variance.

When a materials scientist fails to grow a perfect crystal, or when a metallurgist finds a defect in an annealed sample, it is usually not because the furnace wasn't hot enough. It is because the environment was uncontrolled. A pocket of cool air, a stray oxygen molecule, or a temperature fluctuation of just a few degrees.

This is where the tube furnace distinguishes itself from every other heating element in the lab.

It is not designed for volume. It is designed for isolation.

The Architecture of The Circle

Most industrial ovens are boxes. They are practical, spacious, and good at heating large things. But corners trap dead air, and large volumes create thermal currents.

The tube furnace rejects the square in favor of the cylinder.

The Physics of Uniformity

By surrounding a narrow sample with a cylindrical heating element, the tube furnace creates a thermal environment where heat radiates equidistantly from all sides.

There are no corners. There are no cold spots.

For processes like sintering ceramics or annealing sensitive metals, this geometric symmetry is not a luxury; it is a prerequisite. It ensures that the material properties—strength, conductivity, ductility—are consistent throughout the entire sample.

The Power of "Small"

There is a trade-off here, one that many lab managers struggle with.

To gain precision, you must sacrifice volume. The tube furnace cannot handle bulk manufacturing. It handles small samples with exceptional care. It is a sniper rifle, not a shotgun.

Isolation: Creating a World Within a World

The second "superpower" of the tube furnace is its ability to deny reality.

In a standard oven, your sample is processed in the Earth's atmosphere—nitrogen, oxygen, humidity, and dust. But many advanced materials, such as semiconductors or novel alloys, are ruined by oxidation.

The Sealed Environment

Because the "chamber" is a simple tube, it can be sealed hermetically at both ends. This allows the operator to delete the outside world and replace it with a controlled reality:

- Inert Atmospheres: Flooding the tube with Argon or Nitrogen to prevent oxidation.

- Reactive Atmospheres: Introducing Hydrogen or Carbon for Chemical Vapor Deposition (CVD).

- Vacuum: Removing gases entirely for degassing or sublimation.

This makes the tube furnace the definitive tool for purification and chemical analysis. You aren't just heating a sample; you are defining the exact universe in which that sample exists.

Mastery of Time and Space: The Gradient

A standard oven has one temperature. It is hot everywhere.

Advanced multi-zone tube furnaces challenge this limitation. By segmenting heating elements along the length of the tube, engineers can create a temperature gradient.

Imagine a tube that is 1000°C at one end and 500°C at the other, with a perfectly linear drop in between.

This capability is essential for:

- Crystal Growth: Where materials must transition from liquid to solid at a precise rate.

- Chemical Transport: Moving volatile compounds from a hot zone to a cooler deposition zone.

The Decision Framework

Choosing a furnace is not about budget; it is about constraints.

If your goal is throughput—heating 500 parts an hour—the tube furnace will fail you. Its batch-processing nature and size limitations make it unsuitable for mass production.

However, if your goal is the elimination of variables, it is the only choice.

When to Choose a Tube Furnace

| If your priority is... | Then the Tube Furnace offers... |

|---|---|

| Repeatability | A geometric design that ensures identical thermal exposure every time. |

| Purity | A sealed vessel that allows for vacuum or specific gas environments. |

| Complexity | Multi-zone controls for gradients that box furnaces cannot achieve. |

| Discovery | The ideal R&D environment for synthesizing new materials. |

Engineering Your Success

At KINTEK, we understand that in research and high-precision manufacturing, "good enough" is usually a failure.

We specialize in lab equipment designed for the engineer who requires absolute control. Whether you need the simple elegance of a single-zone heater for sintering or a complex multi-zone system for crystal growth, our tube furnaces are built to master the variables of heat and atmosphere.

Do not let variance dictate your results.

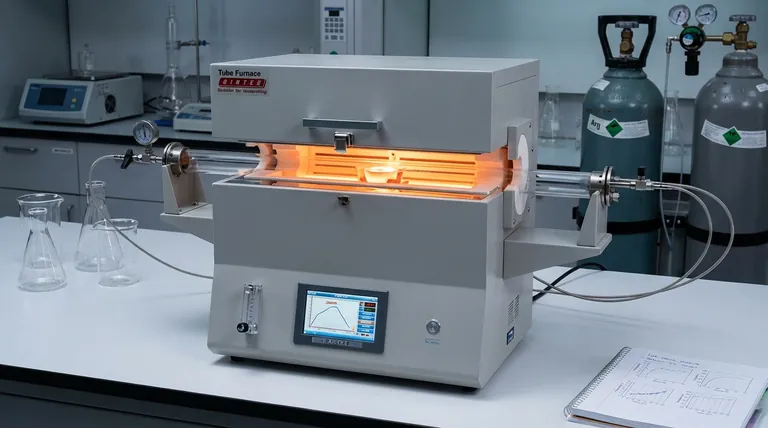

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Related Articles

- The Anatomy of Control: Why Every Component in a Tube Furnace Matters

- High Pressure Tube Furnace: Applications, Safety, and Maintenance

- Why Your High-Temperature Furnace Failed—And How to Prevent It From Happening Again

- Beyond the Spec Sheet: The Hidden Physics of a Tube Furnace's True Limit

- Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit