Introduction to Rotating Disk Electrode (RDE)

Definition and Development

The rotating disk electrode (RDE) was conceived with the primary objective of enhancing the study of current density distribution and mitigating the influence of the diffusion layer. This innovative electrode was first proposed by Levich in 1942, laying the theoretical foundation for its development. The concept was subsequently experimentally validated by Siver and Kabaonv in 1949, solidifying its practical applications in the field of electrochemistry.

The RDE's design allows for a more controlled and predictable analysis of electrochemical processes. By rotating the disc electrode, researchers can manipulate the fluid dynamics around the electrode, thereby achieving a more uniform distribution of current density. This control over the diffusion layer is crucial for accurate measurements and deeper insights into the mechanisms of electrode reactions.

The development of the RDE marked a significant advancement in the field, addressing the limitations of earlier static and vibrating wire electrodes. Its ability to reduce the influence of the diffusion layer and provide a more precise analysis of current density distribution has made it an indispensable tool in modern electrochemical research.

Comparison with Other Electrodes

The Rotating Disk Electrode (RDE) has revolutionized electrochemical studies by addressing several inherent limitations of traditional electrodes. Unlike static electrodes, which suffer from uneven current distribution and uncontrolled diffusion layers, RDEs offer a more uniform and predictable environment. This is achieved through the controlled rotation of the disk electrode, which effectively homogenizes the diffusion layer and enhances the accuracy of current density measurements.

In contrast to classical vibrating wire electrodes, RDEs provide a more stable and reproducible platform for experiments. Vibrating wire electrodes, while useful in certain contexts, often introduce variability due to the mechanical nature of their operation. The rotational mechanism of RDEs, on the other hand, is more reliable and less prone to mechanical failures, making it a preferred choice for long-term and high-precision studies.

The advancements enabled by RDEs have significantly contributed to the field of electrochemistry. By providing a more controlled and consistent environment, RDEs have facilitated the study of complex electrode reactions, the detection of reaction intermediates, and the elucidation of reaction mechanisms. This has led to a deeper understanding of electrochemical processes and the development of more efficient and sustainable electrochemical technologies.

Basic Principle of RDE

Combination of Electrode Theory and Fluid Dynamics

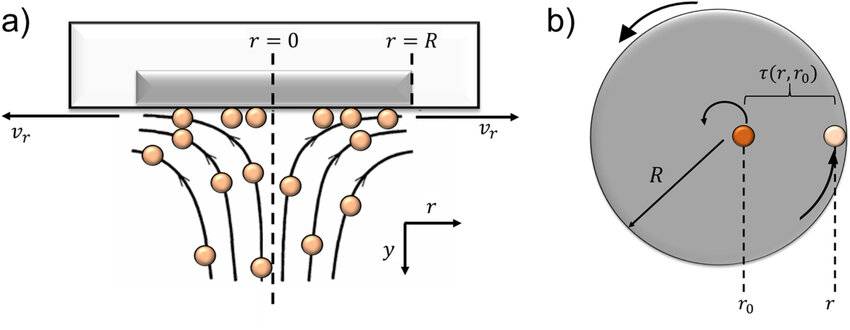

The Rotating Disk Electrode (RDE) synergistically integrates electrode theory with fluid dynamics, a fusion that significantly enhances the control over substance transfer and current density. This integration is achieved through the strategic manipulation of fluid motion, which plays a pivotal role in the operational dynamics of the RDE.

Fluid dynamics within the RDE are meticulously managed to ensure that the diffusion layer, a critical factor in electrochemical reactions, remains uniform and predictable. This control is essential for maintaining consistent current density across the electrode surface, thereby facilitating more accurate and reproducible experimental results. The fluid motion, driven by the electrode's rotation, creates a hydrodynamic flow that continuously replenishes the reactants at the electrode surface, effectively eliminating concentration gradients and ensuring a steady state.

Moreover, the combination of electrode theory and fluid dynamics allows for the precise regulation of mass transport to the electrode. This regulation is crucial for studying reaction kinetics and mechanisms, as it enables researchers to decouple the effects of mass transport from those of the electrode reaction itself. By controlling the fluid dynamics, the RDE provides a robust platform for investigating complex electrochemical processes, offering insights that would be otherwise inaccessible with static or less sophisticated electrodes.

In summary, the RDE's ability to harmonize electrode theory with fluid dynamics not only enhances the control over substance transfer and current density but also broadens the scope of electrochemical research, making it an indispensable tool in modern electrochemistry.

Structural Characteristics

The rotating disk electrode (RDE) is meticulously designed to optimize its performance in electrochemical studies. At its core, the electrode features a disc that is concentric with the rotational axis, ensuring uniform distribution of current density and minimizing edge effects. This design is crucial for maintaining consistent hydrodynamic conditions across the electrode surface.

To further enhance its functionality, the RDE incorporates a thick insulating layer. This layer effectively shields the electrode from potential hydrodynamic edge effects, allowing researchers to focus solely on the central region of the disc. The insulating layer's thickness is carefully calibrated to prevent any interference from the peripheral areas, thereby ensuring that the data collected is representative of the intended experimental conditions.

The surface of the RDE is also a critical aspect of its design. It is meticulously polished to achieve a smooth finish, which minimizes any irregularities that could disrupt the flow of the electrolyte. This smoothness is essential for maintaining uniform mass transfer and current distribution, two key factors in accurately measuring electrochemical reactions.

In summary, the structural characteristics of the RDE, including its concentric disc, thick insulating layer, and smooth surface, collectively contribute to its effectiveness in controlling and analyzing electrochemical processes.

Applications of RDE

Detection of Electrode Reaction Products

The Rotating Disk Electrode (RDE) serves as a powerful tool for the detection of electrode reaction products, intermediates, and their stability. By utilizing the controlled hydrodynamic conditions provided by the RDE, researchers can gain profound insights into the intricate mechanisms of electrode reactions. This capability is particularly valuable in elucidating the complex pathways and transformations that occur during electrochemical processes.

One of the key advantages of RDE in this context is its ability to maintain a steady state, which allows for the continuous monitoring and analysis of reaction intermediates. This steady-state condition is achieved through the uniform distribution of reactants and products across the electrode surface, facilitated by the electrode's rotational motion. As a result, the RDE can provide detailed kinetic data that is crucial for understanding the sequence of reactions and the roles of various intermediates.

Moreover, the RDE's design, which includes a disc concentric with the rotational axis and a thick insulating layer to ignore hydrodynamic edge effects, ensures that the detection of reaction products is not influenced by external factors. This structural characteristic enhances the accuracy and reliability of the data collected, making the RDE an indispensable instrument in the study of electrode reaction mechanisms.

In summary, the RDE's unique combination of electrode theory and fluid dynamics enables it to offer comprehensive insights into the formation, stability, and transformation of electrode reaction products and intermediates, thereby advancing the field of electrochemistry.

Use in Electrochemical Measurements

The Rotating Disk Electrode (RDE) is widely employed in contemporary electrochemical measurements, playing a pivotal role in elucidating intricate processes such as the mechanism of action of electroplating additives. This versatile tool allows for precise control over the diffusion layer, which is crucial for understanding how additives influence the electroplating process. By rotating at controlled speeds, the RDE ensures a consistent and predictable flow of electrolyte, thereby facilitating accurate measurements and detailed analysis of the electrochemical reactions.

Moreover, the RDE's ability to maintain a steady state during measurements makes it an invaluable asset in the study of electroplating additives. This steady state is achieved through the continuous renewal of the electrode surface, which minimizes the effects of surface contamination and ensures reproducible results. The data collected from these measurements can be used to optimize the composition of electroplating baths, enhancing the quality and efficiency of the plating process.

In summary, the RDE's application in electrochemical measurements extends beyond mere data collection; it serves as a critical tool for advancing our understanding of complex electrochemical systems, particularly in the realm of electroplating additives.

Related Products

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Gold Disc Electrode

- Metal Disc Electrode Electrochemical Electrode

- Electrode Polishing Material for Electrochemical Experiments

Related Articles

- Introduction to Rotating Disc Electrodes and Common Electrochemical Applications

- Exploring Rotating Electrode Technology in Electrochemistry

- Comprehensive Guide to Reference Electrodes: Types, Applications, and Selection Criteria

- Innovations in Electrochemical Electrodes Technology

- Comprehensive Guide to Rotating Disk Electrode (RDE) in Electrochemical Studies