You’ve spent days preparing the perfect sample. The powder is mixed, the part is pressed, and the process parameters are programmed with painstaking care. You place it in the high-temperature furnace, and for hours, everything goes according to plan. The temperature climbs steadily to 1600°C and holds perfectly.

Then comes the moment of truth. You open the furnace door, anticipating a dense, strong, perfectly formed component. Instead, you find a part that’s cracked, warped, or has wildly inconsistent properties. Another experiment failed. Another week’s work and expensive materials wasted. You’re left wondering, “What did I do wrong?”

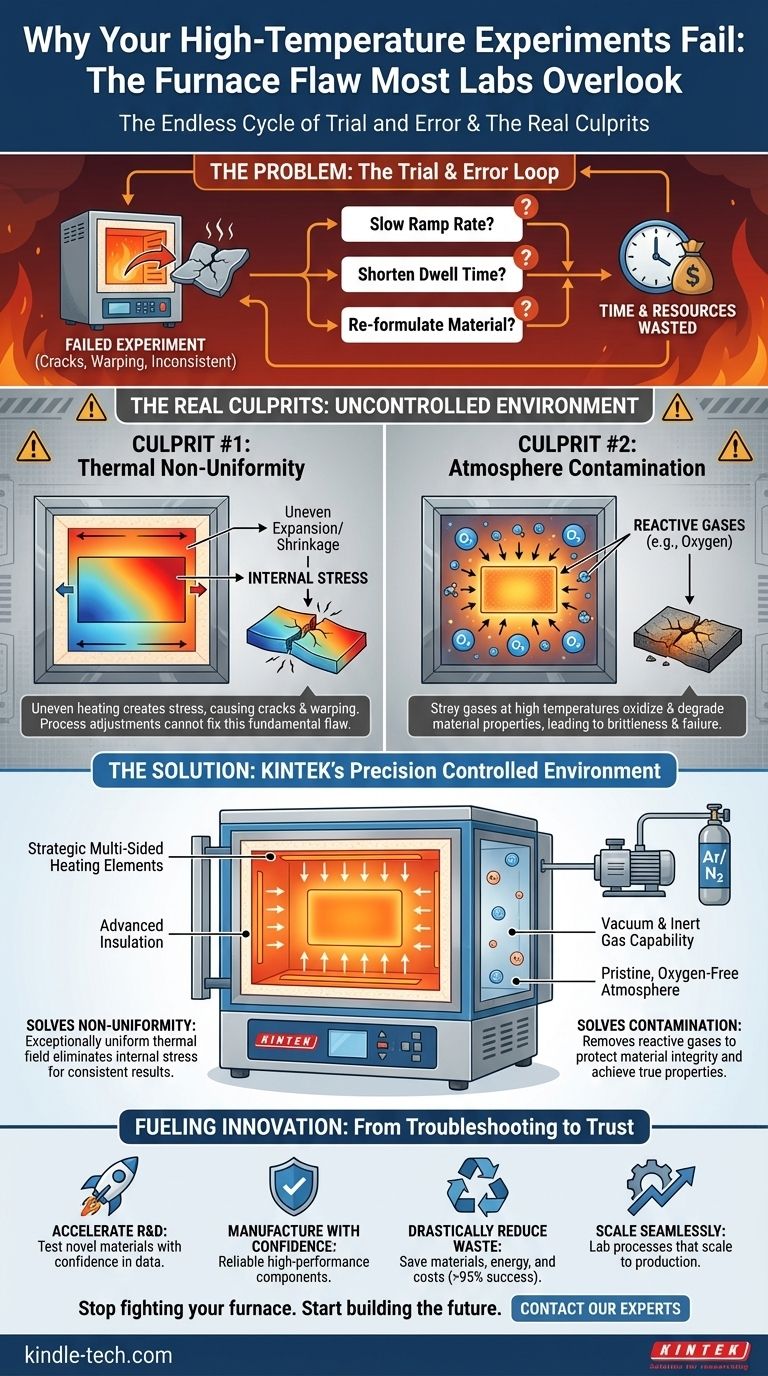

The Endless Cycle of Trial and Error

If this scenario sounds familiar, you’re not alone. Across materials science, aerospace, and medical device R&D, teams constantly battle this exact problem. The common response is to start tweaking the process, initiating an exhausting and often fruitless cycle of adjustments.

You might ask yourself:

- "Did I heat it too quickly?" So you slow the ramp rate.

- "Did I hold it at temperature for too long?" So you shorten the dwell time.

- "Is my material composition slightly off?" So you go back to the drawing board and re-formulate.

Each attempt consumes valuable time, energy, and high-purity materials. More importantly, this guesswork erodes confidence and stalls innovation. When results are not repeatable, you can't trust your data. Projects fall behind schedule, development costs spiral upwards, and the path to manufacturing a reliable, high-performance product becomes impossibly steep. You're stuck troubleshooting your process, when the real problem lies elsewhere.

The Real Culprits: Thermal Uniformity and Atmosphere

The frustrating truth is that your process or material may be perfect. The problem isn't that your furnace reached 1600°C; it's how it got there. The success of any high-temperature process hinges on two critical environmental factors that are often overlooked: thermal uniformity and atmosphere control.

Culprit #1: Thermal Non-Uniformity

Imagine trying to bake a large cake in an oven that’s 50°C hotter on one side. Part of the cake will be burnt, while the other is still raw. A high-temperature furnace with poor thermal uniformity does the exact same thing to your material, but with far more destructive consequences.

If one part of your component is significantly hotter than another, it expands and shrinks at a different rate during heating and cooling. This creates immense internal stress. This stress is the real reason your ceramic parts crack, your metal components warp, and your material properties are inconsistent from one edge to the other.

This is why simply adjusting your heating schedule often fails. You’re trying to use process controls to compensate for a fundamental flaw in the equipment itself—an unevenly heated environment.

Culprit #2: Atmosphere Contamination

At extreme temperatures, even the most stable materials become highly reactive. Any stray oxygen molecules in the chamber can act like a poison. This unwanted oxidation can completely degrade a material's intended properties, turning a high-purity metal into a brittle composite or ruining the electrical performance of an advanced ceramic.

If your experiments yield materials with unexpected brittleness or poor performance, it's often not a failure of the material itself, but a failure to protect it from a contaminated atmosphere during its most vulnerable state.

The Solution: A Controlled Environment, Not Just a Hot Box

To get reliable, repeatable results, you don't need a more complicated process. You need a better, more controllable environment. You need a furnace that was engineered from the ground up to master thermal uniformity and atmosphere control.

This is the core design philosophy behind KINTEK's high-temperature furnaces. They are not just boxes that get hot; they are precision instruments built to create the ideal conditions for material transformation.

-

To Solve Thermal Non-Uniformity: Our furnaces feature strategically placed heating elements on multiple sides of the chamber and advanced insulation. This design creates an exceptionally uniform thermal field, ensuring your entire part experiences the exact same temperature profile. This directly eliminates the internal stresses that cause cracks and warping, delivering consistent and predictable results every time.

-

To Solve Atmosphere Contamination: For sensitive materials, our vacuum and inert-gas furnaces are essential. By removing reactive gases like oxygen, they create a pristine environment that protects your material's integrity. This allows you to achieve the true, uncompromised chemical and physical properties you designed for.

A KINTEK furnace isn't just a tool that gets the job done. It is the embodiment of a deep understanding of what makes high-temperature processes succeed or fail. It is designed to solve the root cause of the problem.

From Fighting Your Furnace to Fueling Innovation

When you can finally trust your equipment, your focus shifts from troubleshooting to true innovation. By eliminating the guesswork and inconsistency, a new world of possibilities opens up.

You can now:

- Accelerate R&D: Confidently test novel materials and processes, knowing that your results are a true reflection of your science, not a lottery of your lab equipment.

- Manufacture with Confidence: Reliably produce high-performance components for critical applications where failure is not an option.

- Drastically Reduce Waste: Move from a 50% success rate to over 95%, saving enormous costs in materials, energy, and man-hours.

- Scale Seamlessly: Develop a robust process in the lab that you can trust to scale to production, because the fundamental principles of thermal control remain consistent.

Your work is about pushing the boundaries of what's possible with materials. Your equipment shouldn't be the thing holding you back. It's time to move beyond fixing failed parts and start building the future. Let us help you ensure your equipment is an accelerator, not an obstacle. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Box Furnace vs. Muffle Furnace: Are You Using the Wrong Tool for the Job?

- Why Your Furnace Experiments Fail: The Hidden Mismatch in Your Lab

- Comprehensive Guide to Muffle Furnaces: Applications, Types, and Maintenance

- Why Your High-Temperature Experiments Fail: It's Not the Heat, It's the Furnace