You’ve done everything by the book. Your materials are pure, your process is meticulous, and your team is sharp. Yet, the results from your high-temperature experiments are inconsistent, or worse, outright failures. Your ashing percentages are all over the map, delicate components come out flawed, and you can’t pinpoint a source of contamination. You’re starting to suspect the one piece of equipment you took for granted: your lab furnace.

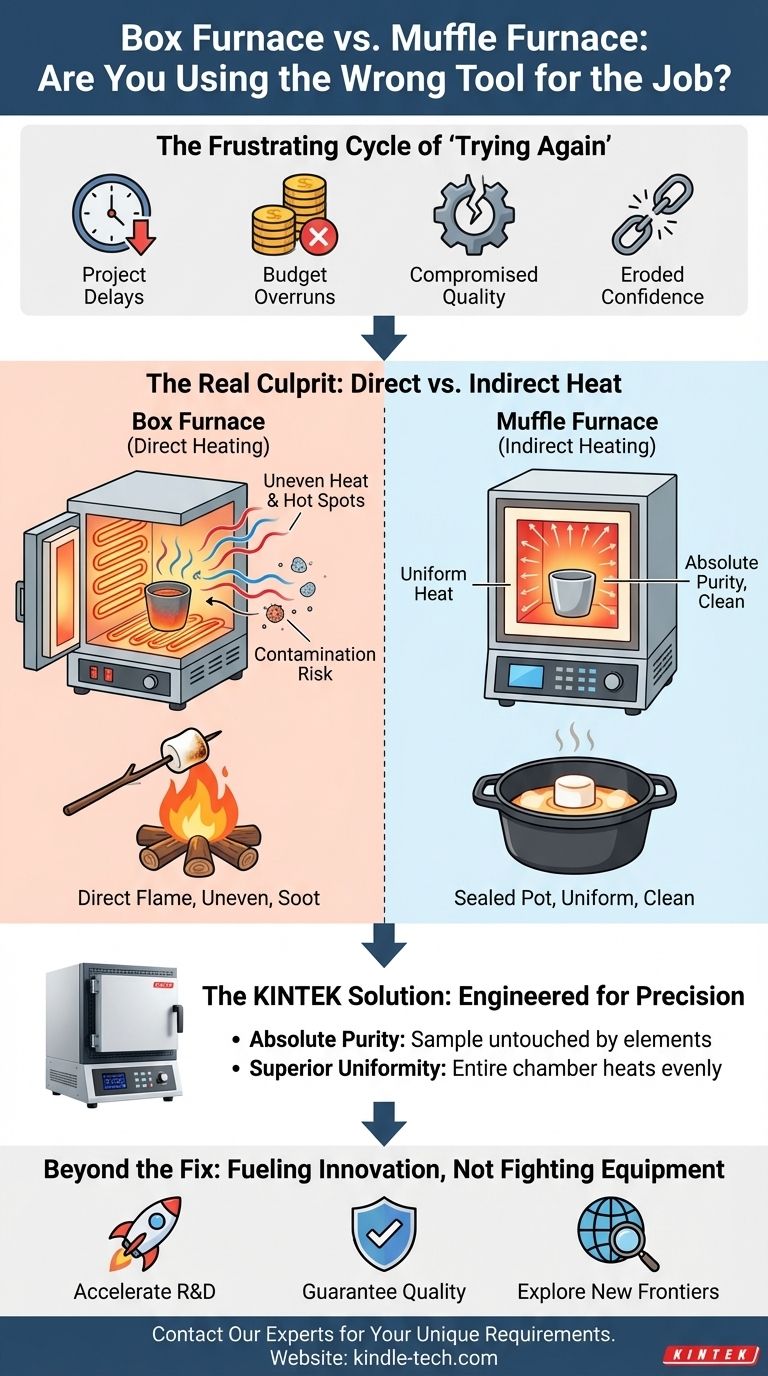

The Frustrating Cycle of "Trying Again"

If this scenario sounds familiar, you are not alone. Across countless labs, researchers find themselves trapped in a costly cycle of re-running tests. They might tweak the temperature profile, try different crucibles, or spend days recalibrating a controller, all in a desperate attempt to achieve consistency.

These aren't just academic frustrations; they have serious business consequences:

- Project Delays: Weeks of progress are lost chasing phantom variables.

- Budget Overruns: Expensive source materials and consumables are wasted on failed runs.

- Compromised Quality: For quality control teams, inconsistent data means you can't confidently sign off on a product's integrity.

- Eroded Confidence: Ultimately, you lose trust in your own lab's data, slowing down innovation and decision-making.

The common belief is that with enough adjustments, the problem will eventually go away. But what if the problem isn't in your process, but is built directly into the furnace you're using?

The Real Culprit: Direct vs. Indirect Heat

The confusion often starts with a simple question of terminology: "box furnace" versus "muffle furnace." Many use the terms interchangeably, assuming they both just mean a rectangular oven that gets very hot. This misunderstanding is the hidden root of countless failed experiments.

The defining difference isn't the external shape—it's the method of heating.

The Flaw of Direct Heating

In a basic box furnace, the heating elements (like coiled wires) are often exposed directly within the heating chamber. Your sample is essentially being cooked by direct, raw radiation from these red-hot elements.

Think of it like toasting a marshmallow directly over a campfire. You get intense heat, but you also get hot spots that cause uneven browning, and soot from the flame can contaminate your marshmallow. In a furnace, this translates to:

- Contamination: As heating elements age, they can shed microscopic particles that fall directly onto your sample, ruining its purity.

- Temperature Non-Uniformity: Direct radiation creates "hot spots," meaning one side of your sample might be significantly hotter than the other, leading to inconsistent material transformations.

No amount of process tweaking can fix this. You're fighting a fundamental design limitation.

The Power of Indirect Heating

A muffle furnace, by contrast, operates on a smarter principle. It contains a separate, sealed inner chamber—the muffle—which is typically made of a uniform ceramic material. The heating elements are outside this chamber.

This time, imagine cooking your marshmallow inside a pre-heated, closed cast-iron pot. The pot itself radiates heat evenly from all sides. The result is a perfectly, uniformly cooked marshmallow with zero contamination from the fire.

This is the muffle principle. The elements heat the muffle, and the muffle provides a clean, perfectly uniform thermal environment for your sample. It physically isolates your work from the two primary sources of failure: contamination and hot spots.

The Solution Embodied: Engineering for Precision

To guarantee pure samples and repeatable results, you don’t just need a box that gets hot. You need a tool specifically designed to create a controlled, uniform heating environment. You need a true muffle furnace.

This is precisely the principle behind KINTEK's laboratory furnaces. We don't just build boxes; we engineer precision instruments. Our muffle furnaces are designed from the ground up to solve the core problem of sample integrity. The sealed, high-purity ceramic muffle isn't an add-on; it's the heart of the machine. It directly addresses and eliminates the root causes of failure that plague simpler designs.

By isolating your sample from the heating elements, a KINTEK muffle furnace delivers the two things that matter most for sensitive applications:

- Absolute Purity: Your sample remains untouched by anything but clean, radiant heat.

- Superior Uniformity: The entire chamber heats to the same temperature, ensuring your entire sample undergoes the exact same process.

Beyond the Fix: Fueling Innovation, Not Fighting Equipment

Once you stop battling your equipment, you unlock your lab's true potential. With a reliable heating process, you can move from troubleshooting to genuine discovery.

- Accelerate R&D: Develop and test new heat-sensitive alloys, polymers, or ceramics faster and with greater confidence.

- Guarantee Quality: Perform definitive ashing for materials analysis or conduct robust quality control on critical components for the aerospace or medical industries.

- Explore New Frontiers: Undertake trace metal analysis or other sensitive chemical processes that were previously impossible due to the high risk of contamination.

Ultimately, having the right tool means you can trust your data, meet your deadlines, and focus on the work that truly drives your business forward.

The difference between a failed test and a breakthrough discovery can come down to the tools you use. If you're tired of inconsistent results and want to ensure your lab is equipped for precision and reliability, our team is here to help. We can help you move beyond the confusing terminology to find the exact solution that solves your technical challenges and achieves your business goals. Let's discuss your project's unique requirements. Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Why Your Furnace Experiments Fail: The Hidden Mismatch in Your Lab

- Comprehensive Guide to Muffle Furnaces: Applications, Types, and Maintenance

- Why Your High-Temperature Experiments Fail: It's Not the Heat, It's the Furnace

- The Architecture of Emptiness: Mastering Material Selection in Vacuum Furnaces