You’ve spent days meticulously preparing your materials. The high-temperature process is set to run overnight. You come into the lab the next morning, open the furnace, and your heart sinks. The sample is ruined—oxidized, contaminated, or simply not transformed as expected. All that time, effort, and expensive material, wasted. Does this sound familiar?

If you're a researcher or engineer working with thermal processing, this scenario is more than just frustrating; it's a critical bottleneck.

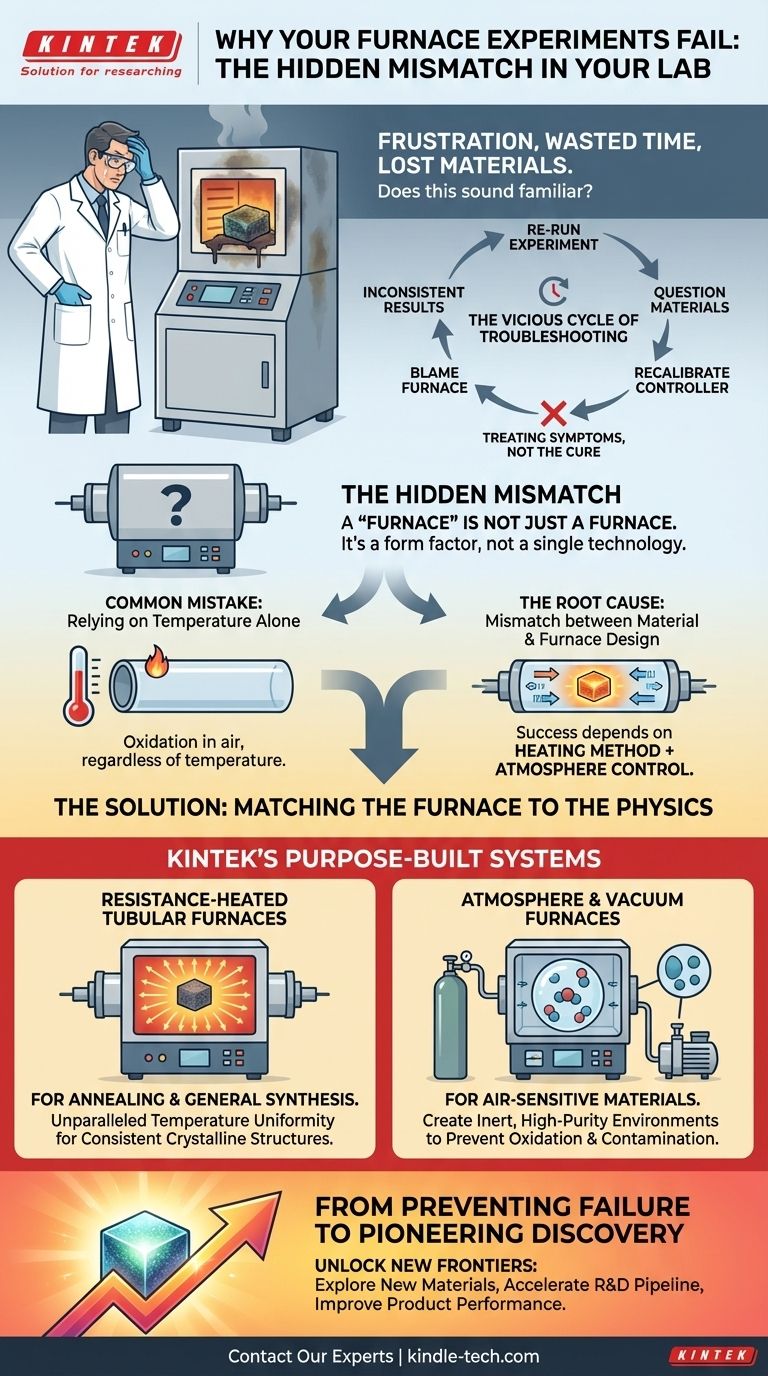

The Vicious Cycle of Troubleshooting: Why Your Best Efforts Fall Short

When an experiment like this fails, the immediate response is a predictable, and often fruitless, cycle of troubleshooting. You might:

- Re-run the experiment, hoping it was a one-time fluke.

- Question your raw materials or sample preparation process.

- Spend hours recalibrating the furnace's temperature controller.

- Blame the furnace itself, assuming it’s “old” or “unreliable.”

After weeks of repeated attempts, the results are still inconsistent. This isn't just an academic puzzle; it has real-world consequences. Project timelines are derailed, R&D budgets are consumed by wasted materials and man-hours, and confidence in your lab’s ability to produce reliable results begins to erode. You're stuck treating the symptoms, but you can't seem to find the cure.

The Hidden Mismatch: A "Furnace" Is Not Just a Furnace

Here is the turning point. What if the problem isn’t your process, your materials, or even a “faulty” furnace? What if the root cause is a fundamental misunderstanding of the tool itself?

Many labs treat a tubular furnace as a simple “hot box.” The common belief is that as long as the temperature is correct, the result should be too. This is the core misconception.

A tubular furnace is not a single technology; it's a form factor. Its success depends entirely on the interplay between its heating method and its atmospheric control capabilities. The real reason for failure is often a hidden mismatch between your material's needs and your furnace's specific design.

Why Common Fixes Don't Work

- Relying on Temperature Alone: If your material is sensitive to oxygen, no amount of temperature recalibration will prevent it from oxidizing in an air-filled tube. The problem isn't the heat; it's the atmosphere.

- Assuming All Furnaces Heat the Same: A standard resistance furnace heats slowly and radiantly from the outside-in, which is perfect for gentle annealing. But if your process requires rapid, direct heating of a metal, this method will fail. You're using the wrong heating principle for the job.

- Using a "Basic" Vacuum: Simply pulling a rough vacuum might not be enough. Many advanced materials require a high-purity inert gas environment (like Argon) to prevent even trace amounts of contamination.

Your troubleshooting efforts were failing because they were focused on the symptoms (e.g., incorrect final product) instead of the disease: a fundamental mismatch between the tool and the scientific task.

The Right Tool for the Job: Matching the Furnace to the Physics

To get consistent, repeatable results, you don't just need a furnace. You need a thermal processing system that is purpose-built to address the specific physics and chemistry of your material.

This is not about finding a magic box; it’s about choosing a tool designed with a deep understanding of these core principles. This is where a specialized furnace from KINTEK becomes your most valuable asset. Our systems are not generic heaters; they are engineered solutions.

-

For Annealing & General Synthesis: Our Resistance-Heated Tubular Furnaces are designed for unparalleled temperature uniformity across the entire heating zone. This ensures that your entire sample experiences the exact same thermal profile, which is critical for achieving consistent crystalline structures and material properties.

-

For Air-Sensitive Materials: Our Atmosphere & Vacuum Furnaces solve the oxidation and contamination problem at its root. They are not just tubes with a pump attached; they are sealed systems engineered with high-integrity flanges and precision gas flow controllers. This allows you to create a truly inert, high-purity environment, enabling you to work with reactive metals, advanced ceramics, and novel 2D materials that would be impossible to process otherwise.

By selecting a furnace based on its core function—be it uniform heating or atmosphere control—you move from guessing to guaranteeing your results.

Beyond Troubleshooting: From Preventing Failure to Pioneering Discovery

When you finally solve this nagging problem of inconsistency, something remarkable happens. The energy your team once spent on troubleshooting is now freed for innovation.

This isn't just about avoiding bad results; it's about unlocking new frontiers for your research.

- Explore New Materials: You can now confidently work with a whole new class of air-sensitive or high-purity materials that were previously off-limits.

- Accelerate Your R&D Pipeline: With reliable, repeatable results, you can move from discovery to validation to scaling up faster than ever before.

- Improve Product Performance: For industrial R&D, achieving the precise material structure means creating a final product with superior performance, reliability, and market value.

Ultimately, having the right thermal processing tool transforms your lab from a place of constant problem-solving into an engine of discovery.

Solving your thermal processing challenges isn't just about a single experiment; it's about building a more reliable, efficient, and innovative research pipeline. Our experts are here to do more than just sell you a piece of equipment; we're here to understand your unique material goals and help you select the precise tool to achieve them. To discuss how we can help you move beyond troubleshooting and toward your next breakthrough, Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Muffle vs. Tube Furnace: How One Choice Prevents Costly Research Failures

- Muffle vs. Tube Furnace: How the Right Choice Prevents Catastrophic Lab Failure

- Why Your Ashing Tests Fail: The Hidden Difference Between Muffle and Ashing Furnaces

- Box Furnace vs. Muffle Furnace: Are You Using the Wrong Tool for the Job?

- Comprehensive Guide to Muffle Furnaces: Types, Uses, and Maintenance