Yes, but the term "mass production" requires careful definition in this context. Carbon nanotubes (CNTs) are indeed produced at an industrial scale, with global capacity reaching thousands of metric tons per year. This production is dominated by a process called chemical vapor deposition (CVD), which has proven far more scalable than the original laboratory methods of arc discharge and laser ablation.

While the capability to produce tons of carbon nanotubes exists, the central challenge for the industry is no longer if they can be mass-produced, but how they can be produced with the consistent quality, purity, and low cost needed to unlock their most transformative applications.

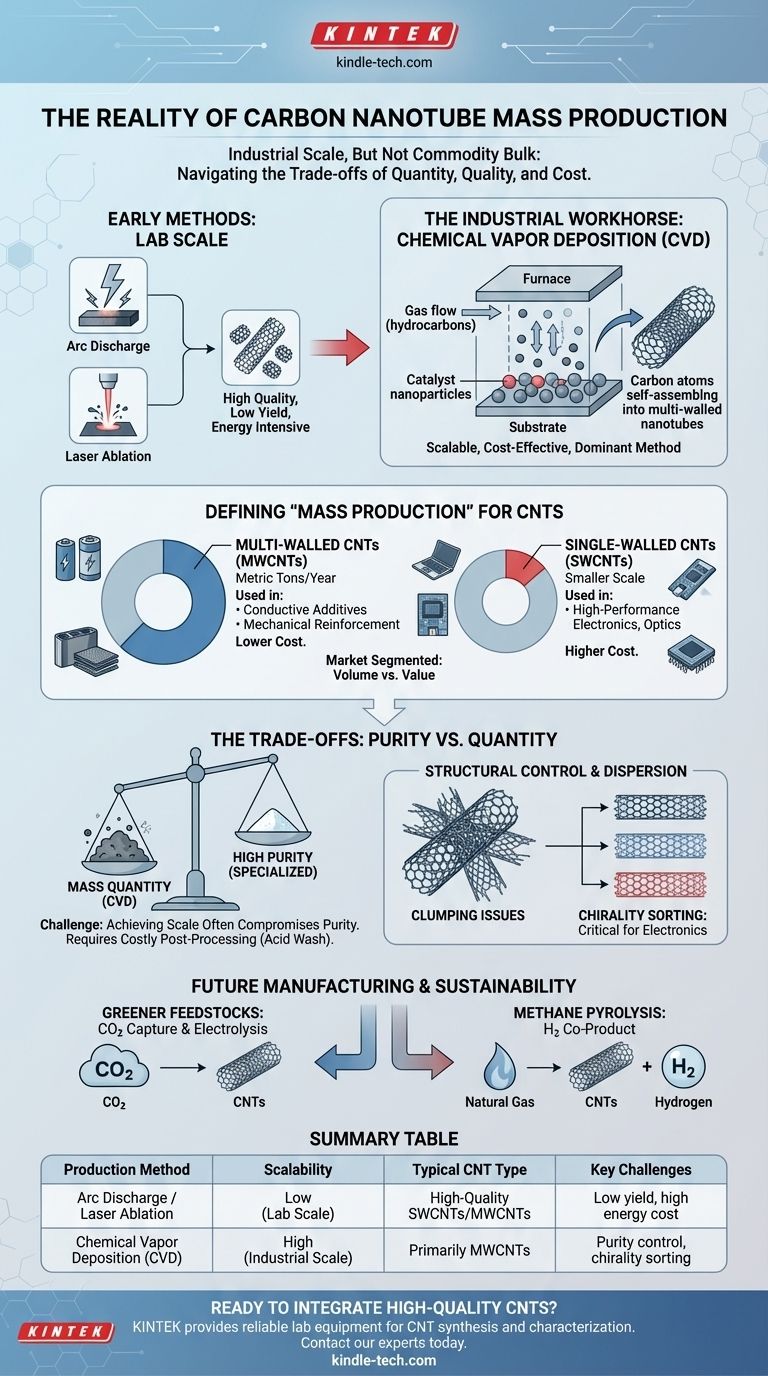

The Evolution of CNT Production: From Lab to Factory

The journey of CNT manufacturing has been a progressive quest for scale and control. Early methods produced high-quality material in tiny quantities, paving the way for the industrial processes used today.

The Early Methods: Arc Discharge and Laser Ablation

The first observations of CNTs were made using arc discharge, where a high-current discharge between two graphite electrodes vaporizes the carbon, which then self-assembles into nanotubes. Similarly, laser ablation uses a high-power laser to vaporize a graphite target.

Both methods can produce very high-quality, crystalline CNTs. However, they are energy-intensive, have very low yields, and are difficult to scale, largely confining them to research and specialized, high-cost applications.

The Commercial Workhorse: Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) is the backbone of the modern CNT industry. In this process, a carbon-containing gas (a hydrocarbon feedstock like methane or ethylene) is passed over a substrate coated with catalyst nanoparticles at high temperatures.

The catalyst particles break down the hydrocarbon gas, and the carbon atoms then reconstruct themselves into nanotube structures. CVD is the dominant method because it offers superior control over the process and, most importantly, is far more scalable and cost-effective than its predecessors.

What "Mass Production" Means for CNTs

When we discuss mass production for CNTs, we are not talking about the scale of bulk commodities like steel or polymers. Production is measured in metric tons per year, not millions of tons.

Furthermore, the market is segmented. The vast majority of this "mass-produced" material consists of multi-walled carbon nanotubes (MWCNTs), which are used primarily as conductive additives or for mechanical reinforcement in composites. Single-walled carbon nanotubes (SWCNTs), which possess superior electronic and optical properties, are far more difficult and expensive to produce and are manufactured at a much smaller scale.

Understanding the Trade-offs in Mass Production

Achieving industrial scale with CNTs has introduced a new set of challenges that define the limitations and opportunities of the technology. The primary trade-off is almost always between quantity and quality.

The Purity vs. Quantity Dilemma

Large-scale CVD processes can generate CNTs quickly and cheaply, but this often comes at the cost of purity. The final product can contain significant amounts of contaminants, such as amorphous carbon and residual metal catalyst particles.

These impurities must be removed through costly and harsh post-processing steps (like acid washes), which can damage the nanotubes themselves and add significantly to the final price.

The Challenge of Structural Control

For advanced applications, especially in electronics, the specific structure of the CNT—its diameter, length, and chirality (the angle of its atomic lattice)—is critical. Chirality determines whether a nanotube behaves like a metal or a semiconductor.

Mass production methods like CVD produce a mix of different types of nanotubes. Sorting them by their electronic properties at an industrial scale remains one of the single greatest hurdles preventing the use of CNTs in next-generation computing.

The Hidden Cost: Dispersion

Even if you have perfectly pure, mass-produced CNTs, they are not easy to use. Due to powerful intermolecular forces, nanotubes clump together in dense, tangled bundles.

Effectively dispersing these bundles into a host material (like a polymer, metal, or liquid) without damaging them is a major downstream manufacturing challenge that every user of CNTs must solve.

The Future of CNT Manufacturing

The industry is actively working to overcome these hurdles, focusing on making the process cheaper, more controlled, and more sustainable.

Greener and Cheaper Feedstocks

Emerging methods aim to replace traditional hydrocarbon feedstocks. Promising research includes using carbon dioxide (CO2) as a feedstock, captured and converted into carbon via electrolysis in molten salts.

Another significant area is methane pyrolysis, which splits natural gas (methane) into solid carbon (forming CNTs) and valuable, clean-burning hydrogen gas. This approach turns a waste product (carbon) into a high-value material and produces a clean energy carrier as a co-product.

Making the Right Choice for Your Application

Selecting the right type and grade of CNT is entirely dependent on your end goal. Understanding the production realities is the first step toward successful implementation.

- If your primary focus is bulk conductive additives or composite reinforcement: Mass-produced, lower-cost MWCNTs from a large-scale CVD process are the most practical and economical choice.

- If your primary focus is high-performance electronics or sensors: You will require highly purified SWCNTs with specific properties, which are produced at a much smaller scale, higher cost, and typically sourced from specialized manufacturers.

- If your primary focus is fundamental research and development: High-purity CNTs produced by specialized CVD or even arc discharge may be necessary to establish baseline performance without the confounding variables of impurities.

Ultimately, navigating the world of carbon nanotubes requires understanding that how they are made is just as important as what they can do.

Summary Table:

| Production Method | Scalability | Typical CNT Type | Key Challenges |

|---|---|---|---|

| Arc Discharge / Laser Ablation | Low (Lab Scale) | High-Quality SWCNTs/MWCNTs | Low yield, high energy cost |

| Chemical Vapor Deposition (CVD) | High (Industrial Scale) | Primarily MWCNTs | Purity control, chirality sorting |

Ready to integrate high-quality carbon nanotubes into your lab workflows? KINTEK specializes in providing reliable lab equipment and consumables tailored for advanced material research, including CNT synthesis and characterization. Whether you're scaling up production or conducting precision R&D, our solutions ensure consistency and performance. Contact our experts today to discuss how we can support your laboratory's carbon nanotube applications.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision