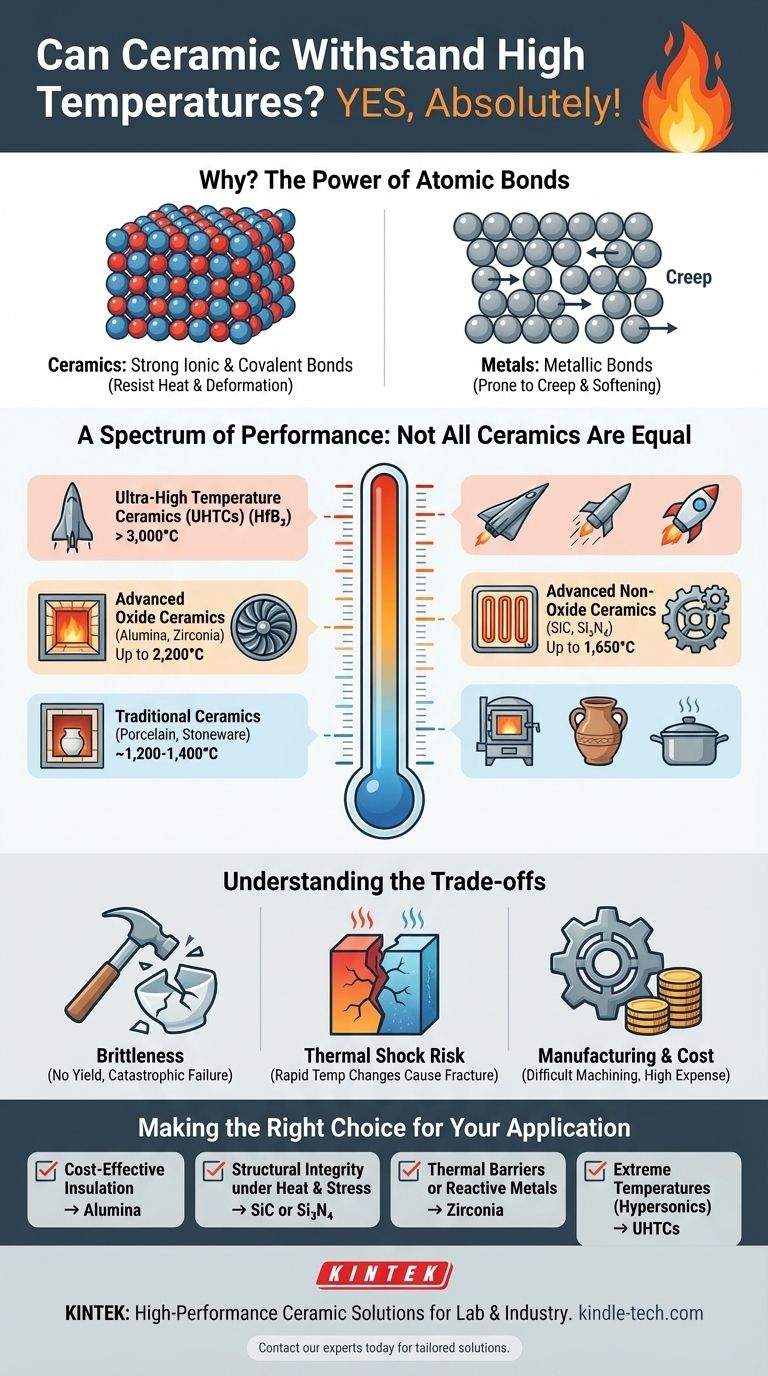

Yes, absolutely. Many ceramics are specifically engineered for their exceptional ability to withstand high temperatures, often far exceeding the limits of even the most advanced metal alloys. However, the term "ceramic" covers a vast category of materials, from common earthenware to specialized technical compounds, each with a vastly different thermal performance.

The core takeaway is that while not all ceramics are the same, a class known as technical ceramics offers superior stability, strength, and creep resistance at extreme temperatures where metals would fail. The crucial trade-off for this performance is their inherent brittleness.

Why Are Ceramics So Heat-Resistant?

To understand why certain ceramics excel in high-heat environments, we have to look at their fundamental atomic structure. This is the key differentiator between ceramics and metals.

The Power of Atomic Bonds

Ceramics are characterized by extremely strong ionic and covalent bonds. These atomic bonds require a tremendous amount of thermal energy (heat) to vibrate and ultimately break.

This powerful bonding is directly responsible for their very high melting points and their ability to maintain structural integrity at elevated temperatures.

A Clear Contrast with Metals

Metals, in contrast, rely on metallic bonds, where electrons are delocalized in a "sea" that flows between atoms. This structure makes metals ductile and malleable.

However, at high temperatures, this atomic arrangement allows atoms to slide past one another more easily, a phenomenon known as creep. This is why metals soften and deform under load at temperatures well below their melting point, a weakness that advanced ceramics do not share to the same degree.

A Spectrum of Performance: Not All Ceramics Are Equal

The specific temperature a ceramic can withstand depends entirely on its chemical composition and crystalline structure. They exist on a wide spectrum of performance.

Traditional Ceramics (Porcelain, Stoneware)

These materials are derived from natural clays and minerals. They have good heat resistance for applications like cookware or pottery kilns, typically serviceable up to around 1,200–1,400°C (2,200–2,550°F).

Advanced Oxide Ceramics (Alumina, Zirconia)

These are a major class of technical ceramics synthesized from pure metallic oxides.

- Alumina (Al₂O₃) is a workhorse material, widely used for furnace linings and insulators, with a maximum service temperature around 1,700°C (3,100°F).

- Zirconia (ZrO₂) is used for thermal barrier coatings on jet engine blades and in crucibles for melting metals, remaining stable up to 2,200°C (4,000°F).

Advanced Non-Oxide Ceramics (Silicon Carbide, Silicon Nitride)

Engineered for extreme mechanical stress at high temperatures, these materials are formed with nitrogen and carbon.

- Silicon Carbide (SiC) retains its strength at temperatures up to 1,650°C (3,000°F) and is used in heating elements and rocket components.

- Silicon Nitride (Si₃N₄) has outstanding thermal shock resistance and is used for high-performance bearings and automotive engine parts.

The Apex: Ultra-High Temperature Ceramics (UHTCs)

This specialized class, including materials like Hafnium Diboride (HfB₂), is designed for the most demanding environments, such as the leading edges of hypersonic vehicles. These materials can potentially withstand temperatures well above 3,000°C (5,400°F).

Understanding the Trade-offs

The exceptional thermal performance of ceramics comes with critical engineering trade-offs that must be managed.

The Brittleness Factor

This is the most significant drawback. Unlike metals, which bend and deform, ceramics are brittle. They do not yield before they break.

This means they are highly susceptible to catastrophic failure from impacts or stress concentrations, requiring careful design to avoid sharp corners or tensile loads.

The Risk of Thermal Shock

Thermal shock is the cracking that occurs from rapid temperature changes.

Because many ceramics have low thermal conductivity, a quick change in external temperature can create immense internal stress between the hot exterior and the cooler interior, causing a fracture. Materials like Silicon Nitride are specifically engineered to combat this weakness.

Manufacturing and Cost Hurdles

Due to their extreme hardness, technical ceramics are very difficult and expensive to machine. Parts are typically formed into their near-final shape through processes like casting or pressing, and then fired (sintered) at high temperatures to achieve their final density and strength.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the specific demands of your environment.

- If your primary focus is cost-effective insulation for furnaces: Alumina is the industry-standard starting point.

- If your primary focus is structural integrity under extreme heat and stress: Look to Silicon Carbide or Silicon Nitride.

- If your primary focus is thermal barrier coatings or melting reactive metals: Zirconia provides exceptional insulation and chemical inertness.

- If your primary focus is surviving the most extreme temperatures imaginable (hypersonics, propulsion): Your only options are in the UHTC family.

Ultimately, harnessing the power of ceramics means embracing their strengths in heat and compression while meticulously designing around their inherent brittleness.

Summary Table:

| Ceramic Type | Key Examples | Max Service Temperature (°C) | Common Applications |

|---|---|---|---|

| Traditional Ceramics | Porcelain, Stoneware | 1,200 - 1,400°C | Cookware, Kiln Linings |

| Advanced Oxide Ceramics | Alumina (Al₂O₃), Zirconia (ZrO₂) | Up to 2,200°C | Furnace Linings, Thermal Barriers |

| Advanced Non-Oxide Ceramics | Silicon Carbide (SiC), Silicon Nitride (Si₃N₄) | Up to 1,650°C | Heating Elements, Engine Parts |

| Ultra-High Temperature Ceramics (UHTCs) | Hafnium Diboride (HfB₂) | Above 3,000°C | Hypersonic Vehicles, Propulsion |

Need a high-temperature ceramic solution tailored to your specific lab or industrial process?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including advanced ceramic components for the most demanding thermal environments. Whether you require durable furnace linings, precision crucibles, or custom-engineered parts, our expertise ensures you get the right material for superior heat resistance, structural integrity, and longevity.

Contact our experts today to discuss how our ceramic solutions can enhance your application's performance and reliability.

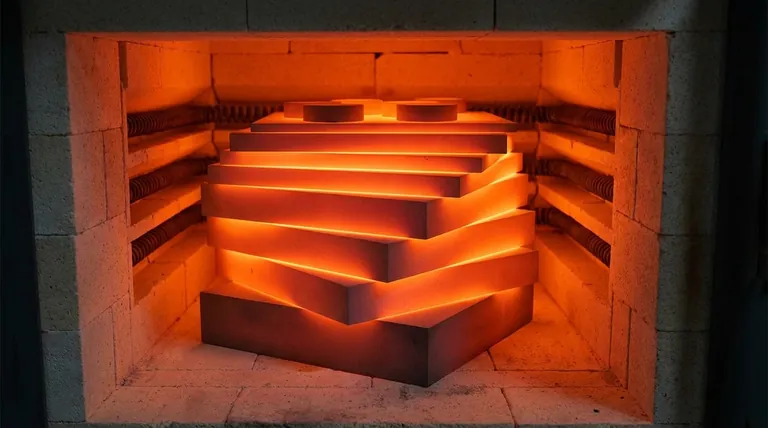

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Flat Corrugated Heat Sink for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What is the thermal expansion of SiC? Master Its Low CTE for Superior High-Temp Performance

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures