Yes, you absolutely must use different crucibles for different types of metals. Using the wrong crucible is not a minor mistake; it can lead to catastrophic failure of the crucible, contamination of your metal, or dangerous chemical reactions in your furnace. The material of the crucible is as critical as the furnace itself for a safe and successful melt.

The core principle is that a crucible is not just a heat-proof container; it is a piece of technical equipment. Its material must be chemically inert to the molten metal it holds and capable of withstanding temperatures well beyond that metal's melting point without degrading.

Why Crucible Material is a Critical Choice

Choosing a crucible is a decision based on chemistry and physics. Molten metals are highly reactive, and overlooking this fact can have serious consequences for your work and your safety.

Thermal Resistance and Shock

A crucible must be able to handle temperatures significantly higher than the melting point of the metal inside it. Equally important is its resistance to thermal shock—the ability to withstand rapid temperature changes without cracking.

Chemical Reactivity

This is the most critical factor. Molten metal can chemically attack and dissolve an incompatible crucible. A classic example is molten aluminum, which is highly reactive and can strip oxygen from the silicon dioxide (silica) found in many basic clay crucibles, weakening them until they fail.

Preventing Metal Contamination

The crucible should not introduce impurities into your melt. A reactive crucible will leach elements into your molten metal, which can ruin the alloy's properties, affect its color, or compromise its structural integrity after casting.

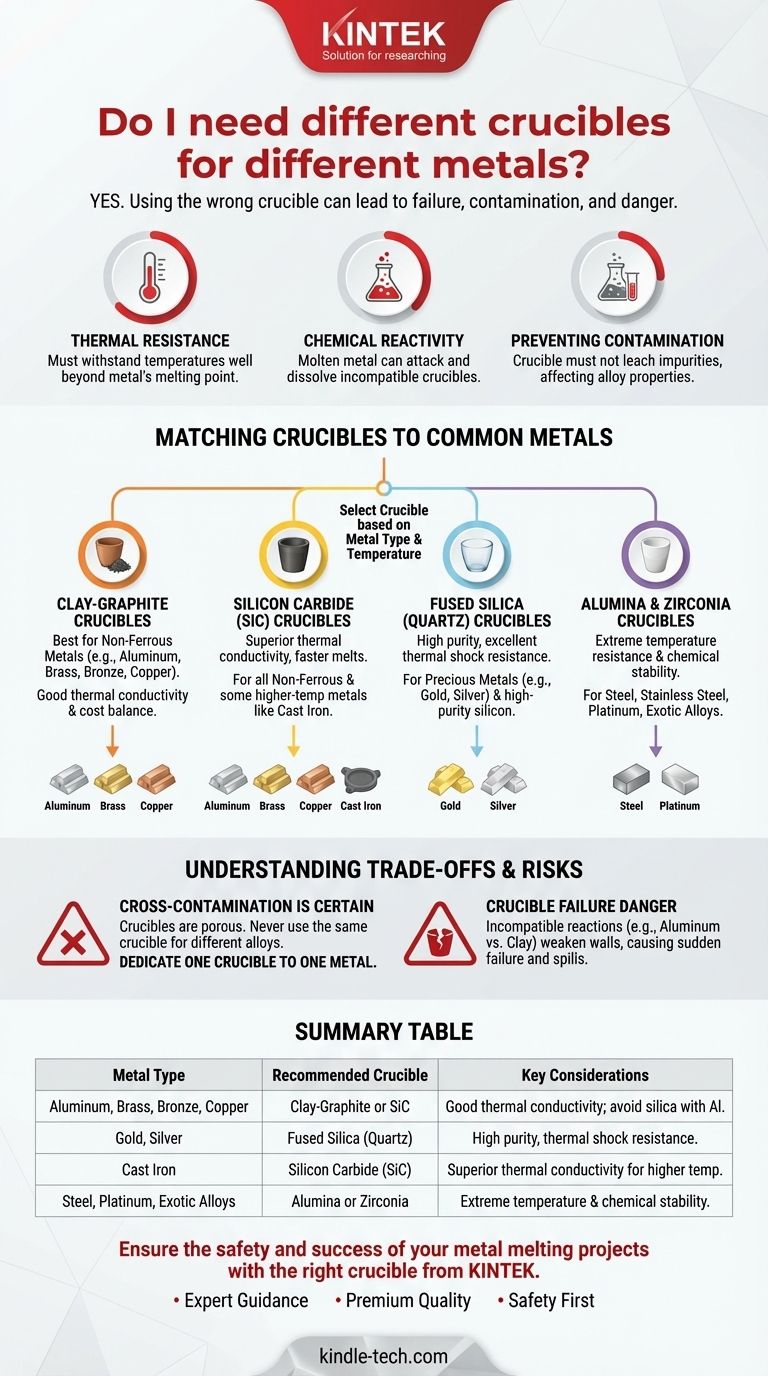

Matching Crucibles to Common Metals

The right choice depends on the metal's melting point and chemical makeup. Crucibles are generally categorized by the metals they are designed to handle.

Clay-Graphite Crucibles

These are the workhorses for many hobbyists and professionals. They offer a good balance of thermal conductivity, mechanical strength, and cost.

They are best suited for non-ferrous metals with lower melting points, such as aluminum, brass, bronze, and copper.

Silicon Carbide Crucibles

This is a step up in performance from standard clay-graphite. Silicon carbide (SiC) crucibles offer superior thermal conductivity, leading to faster melt times and better fuel efficiency.

They are excellent for all common non-ferrous metals and can also handle some higher-temperature melts like cast iron.

Fused Silica (Quartz) Crucibles

These ceramic crucibles are used when purity is paramount. They have excellent thermal shock resistance and are highly non-reactive with many materials.

They are the standard choice for melting precious metals like gold and silver, as well as certain high-purity silicon or glass applications.

Alumina and Zirconia Crucibles

These are highly specialized industrial ceramics designed for extreme temperatures. They are chemically stable at temperatures far exceeding what most other crucibles can handle.

Their use is reserved for very high-temperature metals like steel, stainless steel, platinum-group metals, and other exotic alloys.

Understanding the Trade-offs and Risks

Never assume one crucible can do it all. The risks associated with a poor choice are significant and go beyond simply losing a batch of metal.

The Certainty of Cross-Contamination

Even if a crucible is chemically compatible with two different metals, you should never use the same crucible for different alloys. Crucibles are porous on a microscopic level and will absorb trace amounts of whatever metal you melt.

Using a crucible that once held lead to melt aluminum will contaminate the aluminum with lead. This can create toxic fumes and ruin the properties of the final cast part. Dedicate one crucible to one specific metal or alloy.

The Danger of Crucible Failure

As mentioned, aluminum can destroy a simple clay crucible by chemically reducing the silica within it. This process weakens the crucible wall from the inside out.

The result is often a sudden failure where the bottom or side of the crucible gives way, spilling molten metal inside your furnace, which can destroy the furnace and create an extremely dangerous situation.

Cost vs. Performance

There is a direct correlation between a crucible's performance and its price. A zirconia crucible for melting platinum can cost hundreds or thousands of dollars, while a clay-graphite crucible for aluminum might be under fifty.

The choice is a balance between the value of the metal being melted and the safety requirements of the process.

Making the Right Choice for Your Melt

Your decision should always be guided by safety and the specific requirements of the metal you are working with.

- If your primary focus is common base metals (aluminum, brass, copper): A high-quality clay-graphite or silicon carbide crucible is your most reliable and cost-effective choice.

- If your primary focus is precious metals (gold, silver): Invest in a fused silica crucible and dedicate it exclusively to a single metal to ensure maximum purity.

- If your primary focus is high-temperature alloys (steel, platinum): You require specialized alumina or zirconia ceramic crucibles and must follow manufacturer specifications precisely.

- If your primary focus is purity above all else: Always use a new or strictly dedicated crucible for each distinct alloy to prevent any chance of cross-contamination.

Selecting the correct crucible is the foundation of safe and successful metal casting.

Summary Table:

| Metal Type | Recommended Crucible Material | Key Considerations |

|---|---|---|

| Aluminum, Brass, Bronze, Copper | Clay-Graphite or Silicon Carbide | Good thermal conductivity; avoid silica-based crucibles with aluminum. |

| Gold, Silver | Fused Silica (Quartz) | High purity, excellent thermal shock resistance. |

| Cast Iron | Silicon Carbide | Superior thermal conductivity for higher temperatures. |

| Steel, Platinum, Exotic Alloys | Alumina or Zirconia | Extreme temperature resistance and chemical stability. |

Ensure the safety and success of your metal melting projects with the right crucible from KINTEK.

Choosing the correct crucible is not just about performance—it's about protecting your materials, your equipment, and your safety. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of crucibles designed for specific metals and applications. Whether you're melting aluminum, precious metals, or high-temperature alloys, we have the expertise and products to meet your needs.

Why choose KINTEK?

- Expert Guidance: Get personalized recommendations based on your metal type and melting requirements.

- Premium Quality: Our crucibles are manufactured to withstand thermal shock, prevent contamination, and ensure consistent results.

- Safety First: Avoid dangerous reactions and crucible failure with materials proven for compatibility.

Ready to find your perfect crucible? Contact our experts today for a consultation and let us help you achieve precise, pure, and safe melts every time.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What are the advantages of using alumina crucibles for the TGA of modified alkyd resins? Ensure Accurate Results

- What are the advantages of selecting an alumina crucible for TGA? Ensure High-Precision Thermal Analysis Data

- What temperature can alumina crucible withstand? A Guide to High-Temperature Stability and Safety

- Why are high-purity alumina (Al2O3) crucibles necessary for liquid lead corrosion tests? Ensure Pure Experimental Data

- What is a crucible material for a furnace? A Guide to Choosing the Right High-Temperature Container