Yes, in a practical sense, ceramics are exceptionally strong under pressure. This isn't because the material's internal properties change, but because compressive forces neutralize the microscopic flaws that make ceramics brittle. When you squeeze a ceramic, you are essentially closing the tiny, inherent cracks that would otherwise cause it to shatter under a pulling force.

The immense strength of ceramics under compression is not a change in the material itself. Rather, the compressive load effectively disables the material's greatest weakness—pre-existing micro-flaws—allowing its powerful atomic bonds to bear the load directly.

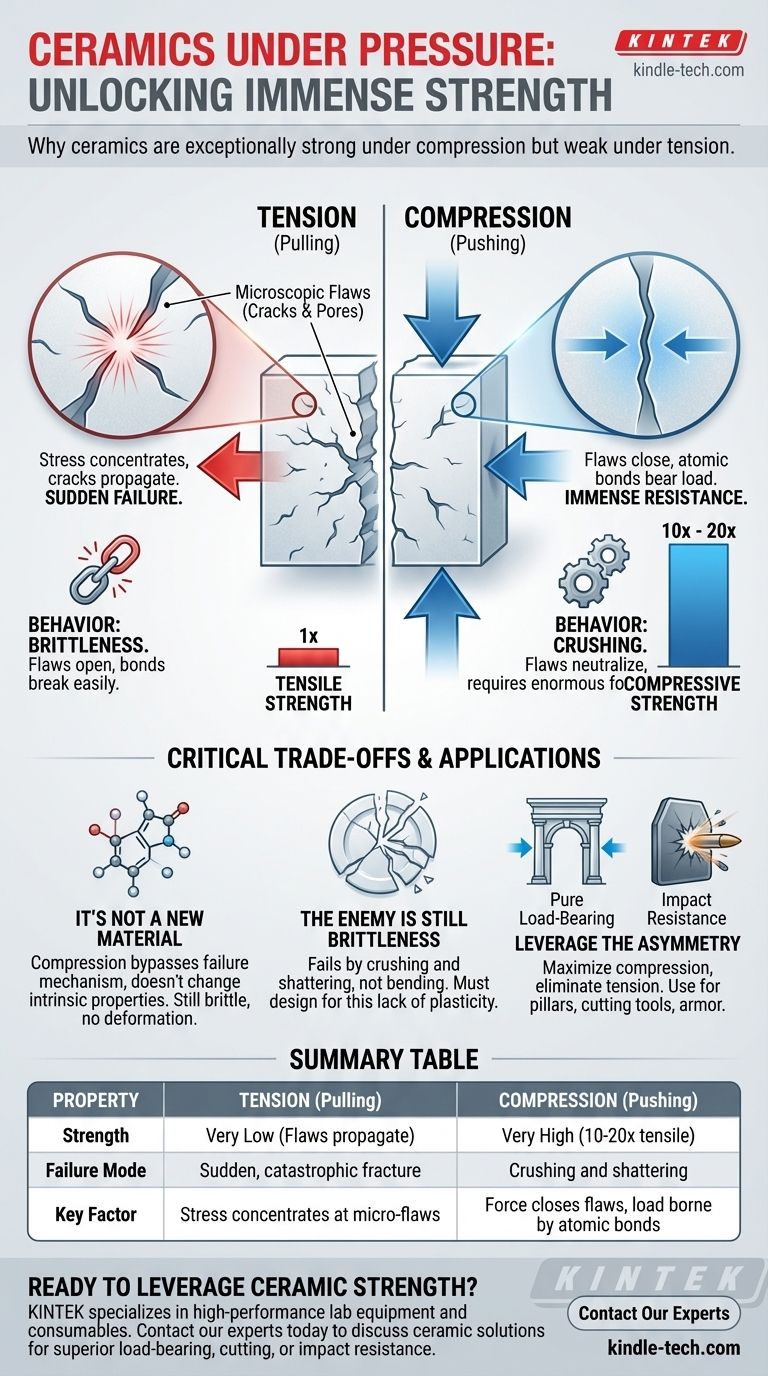

Why Compression and Tension Are Different Worlds for Ceramics

To understand this behavior, you have to look at the material on a microscopic level. The answer lies in the interplay between a ceramic's powerful atomic structure and its inevitable, tiny imperfections.

The Anatomy of a Ceramic

Every ceramic material, no matter how well-manufactured, contains microscopic flaws. These can be tiny pores, grain boundaries, or minute cracks introduced during processing or cooling.

While the ionic and covalent bonds holding the ceramic's atoms together are incredibly strong, these flaws act as points of weakness.

The Behavior Under Tension (Pulling Apart)

When you pull on a ceramic, all the tensile stress concentrates at the sharp tips of these microscopic flaws. This intense concentration acts like a tiny wedge, easily prying the atomic bonds apart.

A single crack begins to grow, or propagate, and because the material is so stiff, the crack travels almost instantly through the entire object. This is why ceramics fail suddenly and catastrophically with very little force under tension, a behavior we call brittleness.

The Behavior Under Compression (Pushing Together)

When you push on a ceramic, the exact opposite happens. The compressive force pushes the sides of these microscopic flaws together, effectively closing them.

With these weak points neutralized, the material's strength is no longer dictated by its flaws. Instead, the load is borne by the entire atomic structure and its powerful chemical bonds. Failure only occurs when the force is so immense that it crushes this structure, which requires an enormous amount of energy.

The Critical Trade-offs and Limitations

While their compressive strength is a massive advantage, it's crucial to understand the context and limitations of this property to use ceramics effectively.

It's Not About Becoming Intrinsically Stronger

A ceramic under compression is not a new or improved material. Its fundamental properties have not changed. The mode of loading—compression—simply bypasses its primary failure mechanism.

If you were to take that same compressed ceramic and subject it to even a small amount of tension (for instance, by bending it), it would still fail at its characteristically low tensile strength.

The Enemy is Still Brittleness

Even under extreme compression, ceramics remain brittle. They do not bend, stretch, or deform before failure like metals do.

When they reach their compressive limit, they fail by crushing and shattering. This lack of plastic deformation is a critical design constraint that must always be considered.

A Tale of Two Strengths

The difference is not minor. The compressive strength of a typical engineering ceramic can be 10 to 20 times greater than its tensile strength.

This dramatic imbalance is the single most important mechanical characteristic to understand when designing with these materials. It is precisely why ancient Roman arches and modern concrete dams function so effectively—they are designed to keep the ceramic material exclusively in a state of compression.

How to Leverage Ceramic Strength in Your Application

Your design strategy must be built entirely around this asymmetry. The goal is always to maximize compression while eliminating tension.

- If your primary focus is pure load-bearing: Ceramics offer unparalleled performance for applications like support pillars, cutting tools, and ballistic armor plates, where the dominant force is compressive.

- If your application involves any bending or pulling: You must design the system to isolate the ceramic from tensile stress, often by using it within a composite structure where another material (like steel rebar in concrete) handles the tension.

- If impact resistance is the goal: Recognize that ceramics absorb impact energy by shattering. In applications like body armor, this is a feature, not a bug, as the ceramic plate breaks apart to dissipate the projectile's kinetic energy.

Understanding this fundamental difference between compressive and tensile behavior is the key to successfully engineering with ceramic materials.

Summary Table:

| Property | Behavior Under Tension (Pulling) | Behavior Under Compression (Pushing) |

|---|---|---|

| Strength | Very Low (Flaws propagate cracks) | Very High (10-20x tensile strength) |

| Failure Mode | Sudden, catastrophic fracture | Crushing and shattering |

| Key Factor | Stress concentrates at micro-flaws | Force closes flaws, load borne by atomic bonds |

Ready to leverage the immense compressive strength of ceramics in your lab or manufacturing process? KINTEK specializes in high-performance lab equipment and consumables, including ceramic components designed for maximum durability and efficiency. Our expertise ensures you get the right materials for applications requiring superior load-bearing, cutting, or impact resistance. Contact our experts today to discuss how our ceramic solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- Why is it necessary to use high-precision temperature-controlled heating furnaces? Secure Natural Fiber Integrity.

- What role do molds play in the formation of Ruthenium sheets? Master High-Density Ruthenium Fabrication

- What are the pros and cons of hot forging? Unlock Superior Strength for Critical Components

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts