At its core, a hot press machine is a device that applies both high temperature and significant pressure to permanently bond, form, or transfer materials. Its function varies dramatically by industry, from applying a graphic to a t-shirt to soldering sensitive electronics or manufacturing plywood. The common thread across all applications is the precise, controlled use of heat and pressure to induce a permanent change.

The term "hot press" does not describe a single device but a broad category of machines. Their unifying principle is the use of controlled heat and pressure to permanently alter materials, whether for decoration, electronic bonding, or industrial lamination.

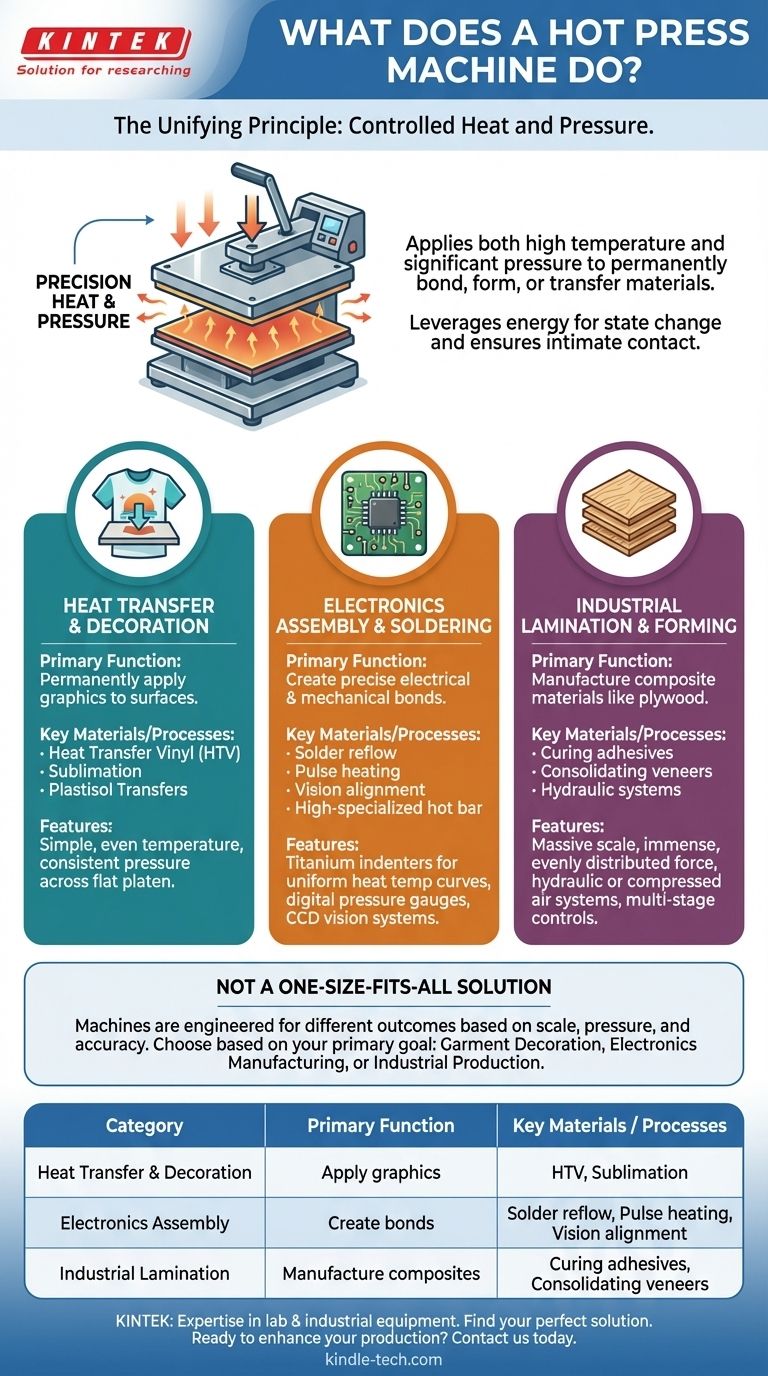

The Unifying Principle: Controlled Heat and Pressure

While the applications are diverse, the physics behind every hot press machine is the same. The machine leverages heat and pressure in a highly controlled manner to achieve a specific outcome.

How Heat Induces Change

Heat provides the energy needed to alter a material's state. In a hot press, this energy is used to melt solder, cure industrial adhesives, or activate heat-sensitive transfer materials.

Advanced machines use methods like pulse heating, which allows for rapid heating and cooling cycles. This precision is critical in applications like soldering, where overheating can damage sensitive electronic components.

The Role of Precision Pressure

Pressure ensures intimate contact between the materials being joined or formed. Without it, heat transfer would be uneven, and the bond or transfer would be incomplete.

In industrial applications, hydraulic systems or compressed air generate immense, evenly distributed force. This pressure ensures that glues or solders flow into every necessary space, creating a strong, permanent, and void-free connection.

Key Applications of Hot Press Technology

The confusion around hot press machines stems from their use in vastly different fields. Understanding the three primary categories clarifies their purpose.

Heat Transfer and Decoration

This is the most common and accessible type of hot press. It is used to permanently apply a design onto a surface, typically fabric, using materials like Heat Transfer Vinyl (HTV), sublimation paper, or plastisol transfers.

These machines are relatively simple, focusing on providing an even temperature and consistent pressure across a flat platen to activate the transfer's adhesive.

Electronics Assembly and Soldering

In electronics manufacturing, a highly specialized hot press (often called a "hot bar reflow soldering machine") is used to create electrical and mechanical connections.

It heats two parts pre-coated with solder to a precise temperature, causing the solder to melt and form a permanent bond upon cooling. These machines often feature CCD vision systems for perfect alignment and multi-stage temperature controls for complex soldering profiles.

Industrial Lamination and Forming

In heavy industry, massive hot presses are used to manufacture composite materials. The most common example is producing plywood, where layers of wood veneer and glue are pressed together under intense heat and pressure.

This process cures the glue and consolidates the veneers into a single, strong sheet. Similar machines are used for laminating decorative surfaces onto particleboard or other substrates.

Understanding the Trade-offs and Key Features

Not all hot press machines are created equal. The features and complexity are directly tied to the intended application and the required level of precision.

The Importance of Precision Control

For simple garment decoration, a few degrees of temperature variance might not be noticeable. For soldering a delicate circuit board, it could mean total failure.

This is why industrial and electronics-grade machines feature titanium indenters for uniform heat, real-time temperature curve displays, and digital pressure gauges. These features are not luxuries; they are essential for repeatable, high-quality results.

Complexity vs. Simplicity

A basic clamshell heat press for t-shirts is manually operated and has simple time and temperature dials. In contrast, an industrial hot press for electronics may have multiple working platforms, stored programs, and a touch-screen interface for process control.

The trade-off is between cost, ease of use, and the level of precision and automation required for the task.

Not a One-Size-Fits-All Solution

The core takeaway is that a machine designed to laminate plywood is fundamentally different from one built to apply vinyl to a hat. While they both use heat and pressure, their scale, pressure capacity, temperature accuracy, and control systems are engineered for entirely different outcomes.

Making the Right Choice for Your Goal

To select the correct machine, you must first define its purpose.

- If your primary focus is decorating garments or custom products: You need a standard heat press designed for transfers like vinyl and sublimation.

- If your primary focus is high-precision electronics manufacturing: You require a hot bar soldering machine with features like pulse heating and vision alignment systems.

- If your primary focus is large-scale industrial production: You need a heavy-duty hydraulic hot press built for laminating or forming materials like plywood.

By recognizing that all hot presses use controlled heat and pressure, you can confidently identify the specific machine engineered for your unique application.

Summary Table:

| Application Category | Primary Function | Key Materials / Processes |

|---|---|---|

| Heat Transfer & Decoration | Permanently apply graphics to surfaces | Heat Transfer Vinyl (HTV), Sublimation |

| Electronics Assembly | Create precise electrical/mechanical bonds | Solder reflow, Pulse heating, Vision alignment |

| Industrial Lamination | Manufacture composite materials like plywood | Curing adhesives, Consolidating veneers |

Ready to find the perfect hot press machine for your application?

Whether you are in garment decoration, electronics manufacturing, or industrial production, KINTEK's expertise in lab and industrial equipment ensures you get a solution tailored to your specific needs. Our hot press machines are designed for precision, durability, and repeatable results.

Contact us today via our [#ContactForm] to discuss your project requirements and discover how KINTEK can enhance your production process with the right technology.

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a sintering press? The Key to High-Performance Powder Metallurgy

- What are the primary functions of a precision hot press in TlBr production? Enhance Semiconductor Crystal Quality

- How hot does a hydraulic press get? Monitor Temperature to Prevent Costly Downtime

- What happens when you compress hot metal? A Guide to Plastic Deformation & Recrystallization

- Why is a laboratory hot press essential for PTFE and nickel foam Zinc-Air electrodes? Precision Microstructure Control

- How does the use of a laboratory hot press influence TlBr crystal quality? Master High-Density Semiconductor Production

- Why is a hot press utilized for 70Li2S-30P2S5 glass-ceramic electrolytes? Maximize Ionic Conductivity & Densification

- What problem does the hot pressing process solve in all-solid-state batteries? Eliminate Interfacial Delamination Now