In many critical applications, yes. Heat treatment is a foundational metallurgical process used to intentionally increase the strength and hardness of specific metals, most notably steel. It achieves this not by adding any material, but by manipulating the metal's internal crystal structure—its microstructure—through a controlled cycle of heating and cooling. The result is a material precisely engineered for a demanding application.

Heat treatment is not a single process but a family of techniques designed to manipulate a metal's properties. While many of these processes significantly increase strength and hardness, this gain almost always involves a trade-off, typically by reducing the material's ductility and making it more brittle.

How Heat Treatment Fundamentally Works

To understand how heat treatment strengthens metal, you have to look at its internal structure. The process is a deliberate manipulation of the metal's crystalline arrangement.

The Role of Microstructure

Metals are composed of microscopic crystals, or "grains." The size, shape, and arrangement of these grains—the microstructure—dictate the material's mechanical properties, including its strength, hardness, and ductility.

Heating, Soaking, and Cooling

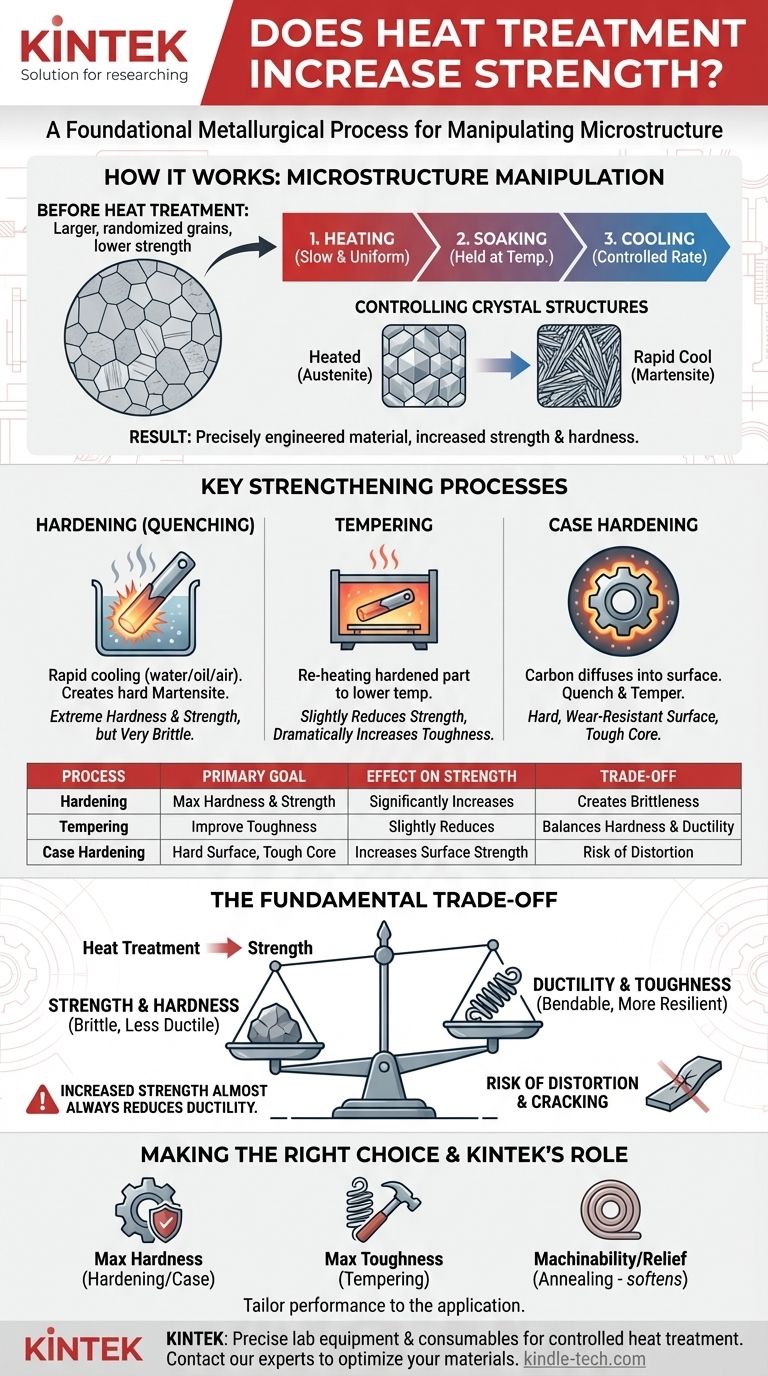

Nearly all heat treatment processes involve three basic stages:

- Heating: The metal is heated slowly and uniformly to a specific temperature.

- Soaking: It is held at that temperature long enough for the desired internal changes to occur throughout the part.

- Cooling: It is cooled back to room temperature at a specific, controlled rate. The speed of this cooling phase is often the most critical factor in determining the final properties.

The Goal: Controlling Crystal Structures

Heating steel above a critical temperature dissolves its carbon content into a structure called austenite. By controlling how fast it cools, you determine the final structure that forms. A very rapid cool (quenching) traps the carbon in a hard, brittle, needle-like structure called martensite, which is responsible for the significant increase in strength and hardness.

Key Heat Treatments That Increase Strength

Different processes are used to achieve different outcomes, but some are specifically designed to maximize strength.

Hardening (Quenching)

This is the most common strengthening process. The steel is heated to form austenite and then rapidly cooled—or quenched—in a medium like water, oil, or air. This rapid cooling creates the hard martensitic structure.

A quenched part is extremely hard and strong but is also very brittle, making it unsuitable for most applications without further processing.

Tempering

Tempering is a secondary process performed immediately after hardening. The hardened part is re-heated to a much lower temperature and held there for a specific time.

This process slightly reduces the extreme hardness and strength but dramatically increases toughness (the ability to resist fracture) and relieves the internal stresses caused by quenching. The final strength is determined by the tempering temperature.

Case Hardening (Carburizing)

For parts that need a very hard, wear-resistant surface but a tough, ductile core (like gears or bearings), case hardening is used. In this process, a low-carbon steel part is heated in a carbon-rich atmosphere.

Carbon diffuses into the surface of the part, creating a "case" with high carbon content. The part is then quenched and tempered, resulting in an extremely hard outer layer while the low-carbon core remains softer and tougher.

Understanding the Trade-offs

Heat treatment is not a "free lunch." Optimizing for one property often means compromising on another. Understanding these trade-offs is essential for any engineering application.

Strength vs. Ductility (The Brittleness Problem)

This is the most fundamental trade-off. As you increase a metal's strength and hardness through heat treatment, you almost always decrease its ductility—its ability to bend or deform without breaking.

An un-tempered, fully hardened piece of steel can be as brittle as glass, shattering under sharp impact. Tempering is the act of trading a little strength for a lot of necessary toughness.

The Risk of Distortion and Cracking

The rapid heating and cooling cycles, especially quenching, induce immense internal stresses within the material. This can cause the part to warp, distort, or even crack during the process, particularly with complex geometries.

Not All Metals Are Equal

Heat treatment is highly dependent on the material's alloy content. Plain carbon steels need a very rapid quench, while certain alloy steels (containing elements like chromium or molybdenum) can be hardened with a much slower cool, reducing the risk of distortion.

Furthermore, not all metals are hardenable in the same way. Most aluminum alloys, for instance, are strengthened through a different process called precipitation hardening, while metals like titanium have their own unique heat treatment procedures.

Making the Right Choice for Your Application

Selecting a heat treatment process depends entirely on the intended use of the component.

- If your primary focus is maximum hardness and wear resistance: A hardening and low-temperature tempering process or case hardening is the correct approach.

- If your primary focus is toughness and impact resistance: A hardening and high-temperature tempering process is used to achieve a better balance of strength and ductility.

- If your primary focus is machinability or relieving internal stress: A different type of heat treatment, like annealing, is used, which actually softens the metal and reduces its strength.

Ultimately, heat treatment provides precise control over a material's properties, allowing you to tailor its performance to a specific engineering need.

Summary Table:

| Heat Treatment Process | Primary Goal | Effect on Strength | Key Trade-off |

|---|---|---|---|

| Hardening (Quenching) | Maximum Hardness & Strength | Significantly Increases | Creates Brittleness |

| Tempering | Improve Toughness | Slightly Reduces | Balances Hardness & Ductility |

| Case Hardening | Hard Surface, Tough Core | Increases Surface Strength | Complex Process, Risk of Distortion |

Need to optimize the strength and durability of your metal components? The right heat treatment process is critical for performance. KINTEK specializes in providing the precise lab equipment and consumables needed for controlled heat treatment processes, from furnaces to quenching media. Our expertise helps laboratories and manufacturers achieve the exact material properties required for their most demanding applications. Contact our experts today to discuss how we can support your materials engineering needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- What are the advantages of vacuum hardening? Achieve Superior Precision and Cleanliness for Critical Components

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service