Yes, the type of solder you use is critically important. The choice directly impacts the melting temperature, the quality and reliability of the electrical connection, and your personal safety. The two main families of solder for electronics, lead-based and lead-free, are not interchangeable and require different techniques and temperatures to use effectively.

Choosing the wrong solder can result in failed projects, damaged components, and even significant health risks. The fundamental decision is between traditional leaded solder for ease of use and modern lead-free solder for safety and regulatory compliance.

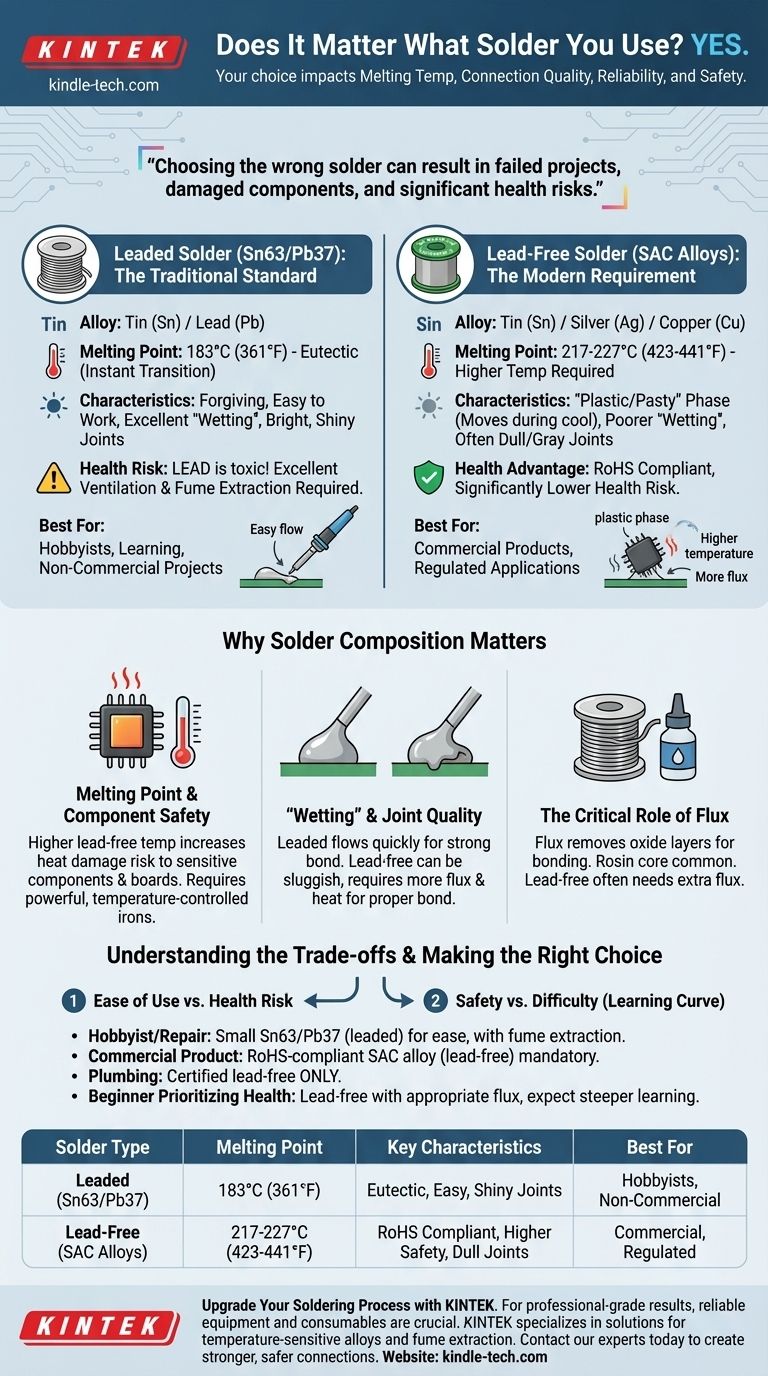

The Two Fundamental Types of Solder

Your first and most important decision is choosing between solder that contains lead and solder that does not. These two categories behave very differently.

Leaded Solder (Sn63/Pb37): The Traditional Standard

The classic electronics solder is an alloy of tin (Sn) and lead (Pb), typically in a 60/40 or 63/37 ratio.

The Sn63/Pb37 alloy is eutectic, meaning it melts and solidifies at a single temperature (183°C / 361°F). This instant transition from liquid to solid makes it extremely forgiving and easy to work with, resulting in bright, shiny joints.

Lead-Free Solder (SAC Alloys): The Modern Requirement

Due to health and environmental concerns, the Restriction of Hazardous Substances (RoHS) directive forced a move to lead-free solder in most commercial electronics.

These solders are typically alloys of tin, silver (Ag), and copper (Cu), known as SAC alloys. They have a significantly higher melting point (around 217-227°C / 423-441°F).

Unlike eutectic leaded solder, lead-free alloys have a "plastic" or "pasty" phase where they are neither fully liquid nor solid. If a component moves during this phase, it can create a weak, unreliable "cold" joint.

Why Solder Composition Matters

The alloy's makeup determines its physical behavior, which has direct consequences for your work.

Melting Point and Component Safety

The higher temperature required for lead-free solder means heat must be applied to the joint for a longer duration. This increases the risk of heat damage to sensitive electronic components and the circuit board itself.

A soldering iron that is not powerful enough will struggle to properly melt lead-free solder, tempting the user to leave the iron on the joint for too long and cause damage.

"Wetting" and Joint Quality

"Wetting" is the ability of molten solder to flow smoothly over and bond with the metal surfaces of the component lead and the circuit board pad.

Leaded solder exhibits excellent wetting action, flowing quickly and easily to create a strong metallurgical bond.

Lead-free solder has poorer wetting characteristics. It can be sluggish and may require more flux and a higher temperature to achieve a proper bond. The resulting joints are often dull or gray in appearance, which is normal.

The Critical Role of Flux

You cannot solder without flux. Flux is a chemical cleaning agent that removes invisible oxide layers from the metal surfaces, allowing the solder to form a proper bond.

Most solder for electronics comes as a wire with one or more cores of rosin flux inside. When the solder melts, the flux is released to clean the joint. For lead-free solder, using additional liquid or paste flux is often necessary to achieve a good result.

Understanding the Trade-offs

Choosing a solder is an exercise in balancing ease of use against safety and compliance.

For Leaded Solder: Ease vs. Health Risk

Leaded solder is far easier to work with, more forgiving for beginners, and produces visually appealing shiny joints. It is the ideal choice for learning and for hobbyist projects where regulations do not apply.

However, lead is a highly toxic substance. Inhaling fumes from soldering with lead requires excellent ventilation and fume extraction. Proper handwashing after handling is essential to avoid ingestion.

For Lead-Free Solder: Safety vs. Difficulty

The primary advantage of lead-free solder is its compliance with RoHS and its significantly lower health risk. It is the only choice for manufacturing commercial products.

The trade-off is a much steeper learning curve. It demands better tools (a temperature-controlled iron is almost mandatory), more precise technique, and a greater need for additional flux to achieve reliable joints.

Making the Right Choice for Your Project

Your choice should be guided by your specific application and priorities.

- If your primary focus is hobbyist electronics or repair: Use a small-diameter (e.g., 0.8mm) Sn63/Pb37 rosin-core leaded solder for its superior ease of use, but ensure you have proper fume extraction.

- If your primary focus is manufacturing a commercial product: You must use a RoHS-compliant lead-free solder, typically a SAC alloy, to meet legal requirements.

- If your primary focus is plumbing or work on potable water systems: Use only certified lead-free plumbing-specific solder as required by law for public health and safety.

- If you are a beginner prioritizing health above all: Start with lead-free solder and appropriate flux, but be prepared for a steeper learning curve and invest in a quality temperature-controlled soldering iron.

Choosing the correct solder for the task is the first step toward creating a reliable, safe, and professional-quality connection.

Summary Table:

| Solder Type | Melting Point | Key Characteristics | Best For |

|---|---|---|---|

| Leaded (Sn63/Pb37) | 183°C (361°F) | Eutectic, easy to use, shiny joints | Hobbyists, learning, non-commercial projects |

| Lead-Free (SAC Alloys) | 217-227°C (423-441°F) | RoHS compliant, higher safety, dull joints | Commercial products, regulated applications |

Upgrade Your Soldering Process with KINTEK

Choosing the right solder is just the beginning. For professional-grade results, you need reliable equipment and consumables that match your solder choice. KINTEK specializes in precision lab equipment and consumables that help electronics professionals and hobbyists achieve perfect, reliable connections every time.

Whether you're working with temperature-sensitive lead-free alloys or need fume extraction for leaded solder safety, KINTEK has the solutions to enhance your workflow and protect your health.

Ready to improve your soldering outcomes? Contact our experts today to discuss your specific needs and discover how KINTEK's laboratory solutions can help you create stronger, safer connections.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Conductive Glass Substrate Cleaning Rack

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- How much electricity does an arc furnace use? The Immense Power Behind Modern Steelmaking

- What are the different types of ash test? Choose the Right Method for Your Material

- What is the most important part of heat treatment? Mastering the Temperature-Time Cycle

- What are the problems for bio oils utilization? Overcome Key Barriers to Renewable Fuel Adoption

- What is the role of an ultrasonic homogenizer in formaldehyde sensor fabrication? Optimize Your Material Dispersion

- What is the disadvantage of an electric arc furnace? High Costs, Inconsistent Heat, and Quality Risks

- What methods can reduce energy consumption in ULT freezers? Slash Energy Costs & Protect Your Samples

- Which is the most preferred material for manufacturing of a semiconductor? Silicon's Dominance Explained