XRF analyzers are highly accurate instruments, capable of delivering lab-quality results directly in the field. They can non-destructively measure elemental concentrations from a few parts per million (ppm) up to 100%, but their precise accuracy in any given situation depends on the specific element, the nature of the sample, and the testing parameters used.

The accuracy of an XRF analyzer is not a single, fixed number but a dynamic capability. Its true value lies in providing rapid, non-destructive, and actionable data that is fit for the purpose, whether that's identifying a metal alloy in seconds or screening for contaminants on-site.

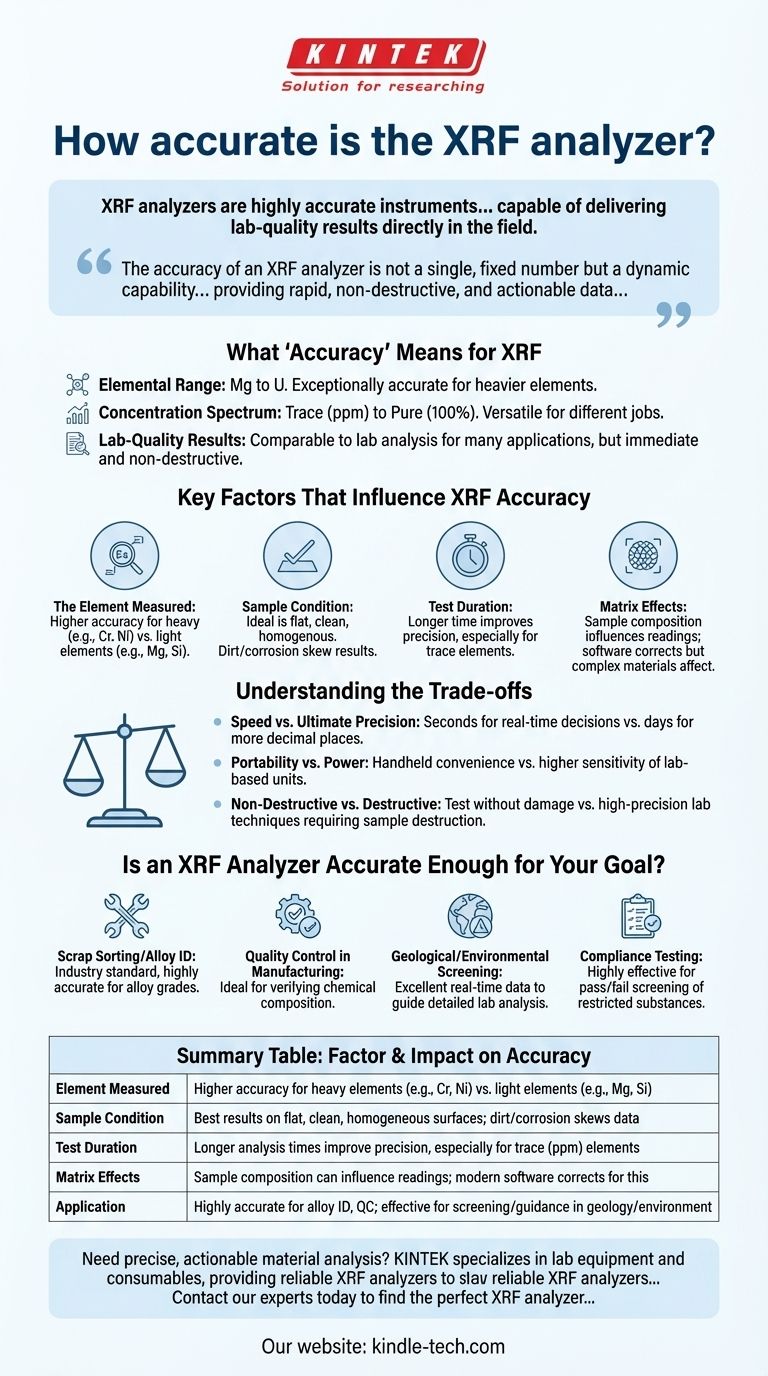

What "Accuracy" Means for XRF

To understand the capability of an XRF analyzer, we must first define what we mean by accuracy in this context. It's more than just getting a "right" or "wrong" answer.

The Role of Elemental Range

XRF analyzers can detect a wide range of elements, typically from magnesium (Mg) to uranium (U) on the periodic table.

Their effectiveness varies across this range. They are exceptionally accurate for heavier elements found in high concentrations, such as identifying the primary components of a steel alloy.

From Percentages to Parts Per Million (PPM)

The instrument can measure across the entire spectrum of concentration, from trace levels (ppm) to pure elements (100%).

This makes them versatile for different jobs, from confirming a material is 99.5% pure aluminum to detecting if a consumer product contains a few hundred ppm of a restricted element like lead.

The Concept of "Lab-Quality" Results

The term "lab-quality" means the results from a handheld XRF are comparable to those from a laboratory for many common applications.

While a dedicated lab using destructive methods might achieve a higher degree of precision, the XRF analyzer provides an immediate, reliable result without the need to cut a sample or wait for days.

Key Factors That Influence XRF Accuracy

The accuracy of any single reading is not absolute. It is directly influenced by a few critical variables that you must understand to get reliable data.

The Element Being Measured

An analyzer's sensitivity is not the same for every element. Generally, it is easier to get highly accurate results for heavier elements (like chromium or nickel) than for very light elements (like magnesium or silicon).

Sample Condition

The ideal sample is flat, clean, and homogenous. An XRF beam analyzes a small surface area, so any dirt, corrosion, coatings, or unevenness can interfere with the reading and skew the results.

Test Duration

A longer test time allows the analyzer's detector to gather more data. This improves the statistical precision of the result, which is especially important when measuring elements present in very low concentrations (ppm).

Matrix Effects

The overall composition of the sample—the "matrix"—can affect the results. X-rays emitted from one element can be absorbed or enhanced by another element in the sample. Modern analyzers have powerful software to correct for these effects, but it remains a factor in complex materials.

Understanding the Trade-offs

Choosing to use an XRF analyzer involves embracing its unique balance of benefits and limitations. Its accuracy must be weighed against its other advantages.

Speed vs. Ultimate Precision

The primary trade-off is speed for precision. You get an answer in seconds, which is incredibly powerful for making real-time decisions like sorting scrap metal.

A formal laboratory analysis might produce a result with more decimal places, but it could take several days and come at a much higher cost.

Portability vs. Power

Handheld XRF analyzers are designed for convenience in the field. This portability means they use smaller, lower-power X-ray tubes than larger, stationary benchtop models found in labs.

For most standard applications, this is not a limitation. However, for specialized analysis of trace elements, a lab-based unit may offer higher sensitivity.

Non-Destructive vs. Destructive

The single greatest advantage of XRF is that it is non-destructive. You can test finished products, historical artifacts, or valuable machinery without causing any damage.

Many high-precision lab techniques require dissolving or destroying the sample, making them unsuitable for countless quality control and inspection scenarios.

Is an XRF Analyzer Accurate Enough for Your Goal?

The answer depends entirely on the decision you need to make. The key is to match the tool's capability to the requirements of the job.

- If your primary focus is rapidly sorting scrap metal or identifying alloys: XRF is the industry standard, providing more than enough accuracy to correctly identify alloy grades in seconds.

- If your primary focus is quality control in manufacturing: It is an ideal tool for verifying that the chemical composition of raw materials or finished parts meets specifications.

- If your primary focus is geological or environmental screening: It provides excellent real-time data to guide more detailed lab analysis, telling you where to focus your efforts.

- If your primary focus is compliance testing for contaminants: It is highly effective for pass/fail screening of materials for restricted substances like lead, cadmium, or mercury.

Ultimately, an XRF analyzer's accuracy is best measured by its ability to provide the right data to make critical decisions with confidence, right when and where they are needed.

Summary Table:

| Factor | Impact on Accuracy |

|---|---|

| Element Measured | Higher accuracy for heavy elements (e.g., Cr, Ni) vs. light elements (e.g., Mg, Si) |

| Sample Condition | Best results on flat, clean, homogeneous surfaces; dirt/corrosion skews data |

| Test Duration | Longer analysis times improve precision, especially for trace (ppm) elements |

| Matrix Effects | Sample composition can influence readings; modern software corrects for this |

| Application | Highly accurate for alloy ID, QC; effective for screening/guidance in geology/environment |

Need precise, actionable material analysis?

KINTEK specializes in lab equipment and consumables, providing reliable XRF analyzers that deliver the speed, portability, and non-destructive testing capabilities your laboratory demands. Whether you're sorting alloys, conducting quality control, or screening for contaminants, our solutions are designed to provide the accurate data you need to make confident decisions.

Contact our experts today to find the perfect XRF analyzer for your specific application and see how we can enhance your lab's efficiency and accuracy.

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Aluminum Foil Current Collector for Lithium Battery

People Also Ask

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability

- How does ultrasonic dispersion equipment contribute to GO-PANI synthesis? Engineering Superior Nanocomposites

- What would be an advantage of biomass over the use of coal? A Cleaner, Carbon-Neutral Energy Source

- What is the purpose of using a glass vacuum desiccator after drying biomass? Ensure Precise Sample Data Integrity

- What is the temperature of microwave sintering? Achieve Faster, Lower-Temperature Densification

- What type of plastic is usually used with compression molding and transfer molding? Master Thermosets for Superior Performance

- What is high temperature sintering of ceramics? Transform Powder into Dense, High-Performance Components

- What is the main problem with biomass energy? The Sustainability Contradiction Explained