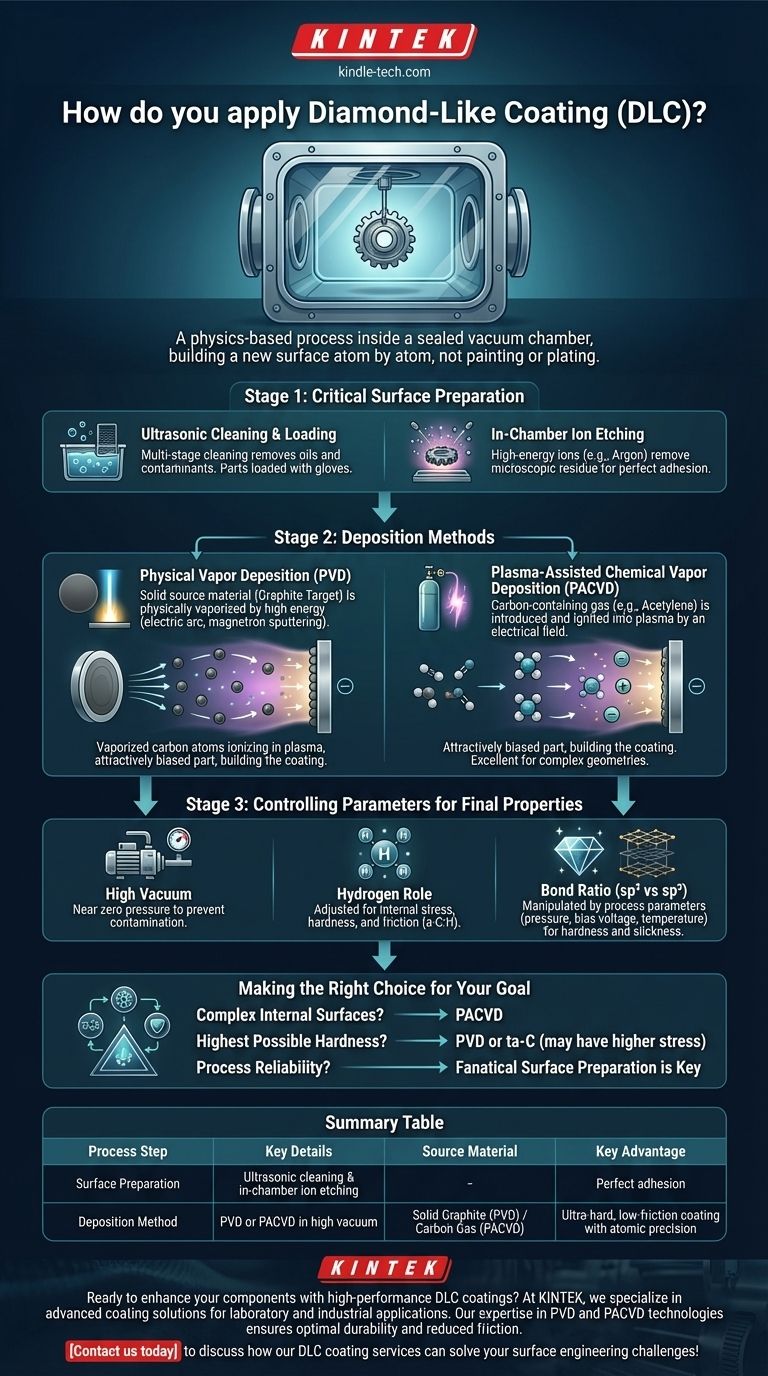

In short, Diamond-Like Carbon (DLC) coatings are applied using advanced vacuum deposition techniques. The most common methods are Physical Vapor Deposition (PVD) and Plasma-Assisted Chemical Vapor Deposition (PACVD). Both processes take place inside a sealed vacuum chamber where a source material—either solid carbon or a carbon-containing gas—is transformed into a plasma and deposited onto the target component atom by atom, forming a dense, hard, and slick film.

The core principle is not one of painting or plating, but of building a new surface. The process uses high energy in a vacuum to break down source materials into their atomic components and reassemble them as a highly-engineered, diamond-like film on the part's surface.

The Foundation: Why Surface Preparation is Critical

Before any coating can begin, the substrate (the part being coated) must be impeccably clean. The performance of a multi-thousand-dollar coating job can be completely undermined by a microscopic speck of oil or residue.

### The Cleaning and Loading Process

Parts undergo a multi-stage ultrasonic cleaning process using special detergents and solvents to remove all machining oils, grease, and handling contaminants. They are then carefully loaded onto fixtures within the vacuum chamber, a process that must be done with gloves to avoid re-contamination.

### In-Chamber Ion Etching

Once a vacuum is established, the process often begins with a final, atomic-level cleaning step. High-energy ions, typically of an inert gas like Argon, are used to bombard the part's surface. This "ion etching" or "sputter cleaning" removes any remaining microscopic oxides or contaminants, creating a pure, highly receptive surface for the DLC film to adhere to.

The Core Process: An Overview of Deposition Methods

With a perfectly prepared surface, the actual deposition can begin. While there are many variations, the two dominant industrial methods are PVD and PACVD.

### Method 1: Physical Vapor Deposition (PVD)

PVD creates the coating material by physically vaporizing a solid source material. For DLC, this is typically a high-purity graphite target. The process broadly follows three stages.

- Vaporization: A high-energy source, such as an electric arc or a magnetron sputtering source, bombards the solid graphite target. This impact is energetic enough to knock carbon atoms loose, converting the solid directly into a vapor.

- Transportation: The vaporized carbon atoms travel through the vacuum chamber. The chamber is filled with a low-pressure gas that is energized into a plasma, an ionized state of matter. The carbon atoms are ionized within this plasma.

- Deposition: The parts being coated are given a negative electrical charge (a bias). This attracts the positively charged carbon ions from the plasma, causing them to accelerate towards and impact the surface with very high energy. This bombardment is what builds the dense, well-adhered, and hard DLC film.

### Method 2: Plasma-Assisted Chemical Vapor Deposition (PACVD)

PACVD uses a similar principle but starts with a gas instead of a solid.

- Gas Introduction: A carbon-containing gas, most commonly acetylene (C₂H₂), is precisely introduced into the vacuum chamber.

- Plasma Reaction: An electrical field is applied to the chamber, igniting the gas into a plasma. This high-energy environment breaks the gas molecules apart into various reactive, carbon-containing ions and radicals.

- Deposition: As with PVD, the parts are negatively biased. This attracts the positive carbon ions from the plasma, which deposit onto the surface and build the DLC film. This method is excellent for coating complex internal geometries, as the gas can flow into areas that a line-of-sight PVD source cannot reach.

Understanding the Trade-offs and Critical Parameters

The success of a DLC coating is not just about choosing a method; it's about controlling the environment with extreme precision.

### The Need for a Vacuum

All DLC deposition happens in a high vacuum (near zero pressure). This is critical to remove air and other molecules that would otherwise contaminate the coating, creating defects and causing it to fail.

### The Role of Hydrogen

Many DLC films are created with hydrogen (designated a-C:H). In PACVD, hydrogen is naturally present from the acetylene gas. In PVD, hydrogen gas may be added intentionally. The amount of hydrogen incorporated into the film is a key parameter for controlling its internal stress, hardness, and friction coefficient.

### Controlling the Final Properties

The final performance of the coating—its hardness, slickness, and durability—is determined by precisely controlling the ratio of diamond-like (sp³) and graphite-like (sp²) atomic bonds. This ratio is manipulated by adjusting process parameters like gas pressure, the energy of the bombarding ions (bias voltage), and temperature.

Making the Right Choice for Your Goal

The method and specific "recipe" used to apply a DLC coating are chosen based on the part's geometry, the base material, and the desired final performance characteristics.

- If your primary focus is coating complex internal surfaces: PACVD is often the superior choice because the precursor gas can reach areas that are not in the direct line of sight of a solid PVD target.

- If your primary focus is achieving the highest possible hardness: Certain PVD processes or hydrogen-free DLC variants (ta-C) can produce harder, more diamond-like films, but they may also have higher internal stress.

- If your primary focus is process reliability for any application: The most critical factor is not the deposition method itself, but the fanatical attention paid to cleaning and surface preparation before the process even begins.

Ultimately, applying a diamond-like coating is a sophisticated physics-based process that engineers a surface at the atomic level to achieve unparalleled performance.

Summary Table:

| Process Step | Key Details |

|---|---|

| Surface Preparation | Multi-stage ultrasonic cleaning and in-chamber ion etching for perfect adhesion |

| Deposition Method | PVD (Physical Vapor Deposition) or PACVD (Plasma-Assisted Chemical Vapor Deposition) |

| Environment | High vacuum chamber to prevent contamination |

| Source Material | Solid graphite (PVD) or carbon-containing gas like acetylene (PACVD) |

| Key Advantage | Creates ultra-hard, low-friction coating with atomic-level precision |

Ready to enhance your components with high-performance DLC coatings?

At KINTEK, we specialize in advanced coating solutions for laboratory and industrial applications. Our expertise in PVD and PACVD technologies ensures your parts receive the optimal diamond-like coating for maximum durability, reduced friction, and extended service life.

Whether you need to coat complex geometries or require the highest hardness specifications, our team will deliver precise, reliable results.

Contact us today to discuss how our DLC coating services can solve your surface engineering challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Isostatic Molding Pressing Molds for Lab

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

People Also Ask

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition