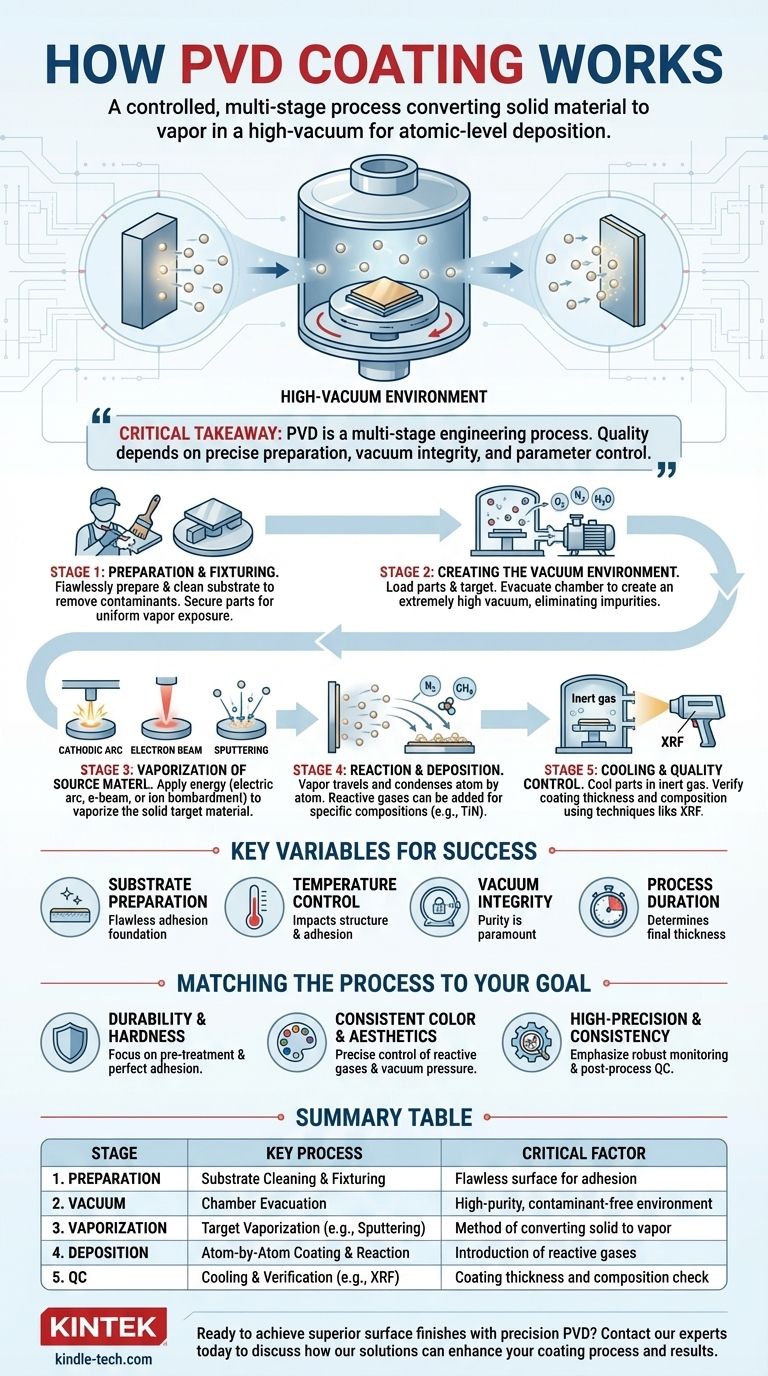

At its core, the Physical Vapor Deposition (PVD) coating process transforms a solid material into a vapor within a high-vacuum environment and then deposits it, atom by atom, onto the surface of a part. This multi-stage process includes meticulous preparation of the substrate, creating the vacuum, vaporizing the source material, depositing the coating, and implementing strict quality controls.

The crucial takeaway is that PVD is not a single action but a highly controlled, multi-stage engineering process. The quality of the final coating is determined less by the deposition itself and more by the precision of the preparation, the integrity of the vacuum, and the control over process parameters like temperature and pressure.

The Foundational Stages of the PVD Process

To truly understand how PVD works, it's best to break it down into the distinct phases that occur within and around the vacuum chamber. Each step is critical for achieving a uniform, durable, and high-performance coating.

Stage 1: Preparation and Fixturing

Before any coating can begin, the part to be coated—the substrate—must be flawlessly prepared. This often involves stripping old coatings and performing a multi-step, intensive cleaning to remove any contaminants.

Once clean, parts are mounted on specialized fixtures. This fixturing is essential for ensuring all critical surfaces are exposed to the vapor stream for uniform coating thickness.

Stage 2: Creating the Vacuum Environment

The fixtured parts and the source material (the target) are loaded into the PVD chamber. The chamber is then sealed and evacuated to create an extremely high vacuum.

This vacuum is non-negotiable. It removes atoms and molecules like oxygen, nitrogen, and water vapor that would otherwise react with the coating vapor, creating impurities and compromising the coating's integrity and adhesion.

Stage 3: Vaporization of the Source Material

With the vacuum established, energy is introduced to the chamber to vaporize the solid target material. The specific method used is a key differentiator in PVD processes.

Common techniques include:

- Cathodic Arc: A high-current electrical arc is used to vaporize and ionize the metal target.

- Electron Beam: A focused beam of high-energy electrons heats and evaporates the target material.

- Sputtering: The target is bombarded with energetic ions (often argon) from a plasma, which physically knocks atoms off its surface.

Stage 4: Reaction and Deposition

The vaporized material travels in a straight line through the vacuum and condenses on the cooler substrates. This deposition happens atom by atom, building a thin, dense, and highly-adherent film.

To create specific coating compositions (like titanium nitride for hardness or zirconium nitride for a gold color), reactive gases such as nitrogen or methane are precisely introduced into the chamber. These gases react with the metal vapor to form the desired ceramic compound on the part's surface.

Stage 5: Cooling and Quality Control

After the coating cycle is complete, the chamber is backfilled with an inert gas to help cool the parts. Once removed, the coated components undergo rigorous quality control.

Techniques like X-Ray Fluorescence (XRF) are used to verify the coating's thickness and composition, ensuring it meets the exact specifications required for the application.

Key Variables That Define a Successful Coating

The difference between a flawless coating and a failed one lies in the control of several critical process parameters. Understanding these is key to evaluating the quality of a PVD operation.

Substrate Preparation

A coating can only be as good as the surface it is applied to. Any residual oils, dust, or oxides will prevent proper adhesion, leading to flaking or delamination. This is the most common point of failure.

Temperature Control

The temperature of the substrate during deposition significantly impacts the coating's structure, adhesion, and internal stress. Consistent and appropriate temperature control is essential for repeatable results.

Vacuum Integrity

Maintaining a high-purity vacuum throughout the process is paramount. Even a microscopic leak can introduce contaminants that ruin the entire batch, resulting in a soft, discolored, or poorly-adhered coating.

Process Duration

The length of the deposition cycle, typically ranging from 30 minutes to a few hours, directly determines the final thickness of the coating. This must be precisely controlled to meet performance requirements without creating unnecessary internal stress.

Matching the Process to Your Goal

Understanding the "how" of PVD allows you to make better decisions based on your specific objective. The details of the process should be tailored to the desired outcome.

- If your primary focus is durability and hardness: Pay close attention to the pre-treatment and cleaning stages, as perfect adhesion is the foundation of a tough coating.

- If your primary focus is consistent color and aesthetics: The precise control of reactive gases and vacuum pressure is the most critical factor for achieving the target color batch after batch.

- If your primary focus is high-precision and consistency: Seek out processes that emphasize robust in-process monitoring and post-process quality control, including thickness and composition verification.

Ultimately, a successful PVD coating is the result of a disciplined and scientifically controlled process from start to finish.

Summary Table:

| Stage | Key Process | Critical Factor |

|---|---|---|

| 1. Preparation | Substrate Cleaning & Fixturing | Flawless surface for adhesion |

| 2. Vacuum | Chamber Evacuation | High-purity, contaminant-free environment |

| 3. Vaporization | Target Vaporization (e.g., Sputtering) | Method of converting solid to vapor |

| 4. Deposition | Atom-by-Atom Coating & Reaction | Introduction of reactive gases (e.g., Nitrogen) |

| 5. Quality Control | Cooling & Verification (e.g., XRF) | Coating thickness and composition check |

Ready to achieve superior surface finishes with precision PVD?

KINTEK specializes in high-performance lab equipment, including PVD systems and consumables, designed to deliver the durable, consistent, and high-quality coatings your laboratory demands.

Contact our experts today to discuss how our solutions can enhance your coating process and results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings