At its core, a vacuum press doesn't press at all. Instead, it cleverly removes air from one side of your project, allowing the full weight of the Earth's atmosphere to do the work. By placing materials inside a sealed bag and evacuating the air, you create a low-pressure environment, causing the higher atmospheric pressure outside the bag to apply immense, perfectly uniform force.

A vacuum press is not a machine that applies force, but one that removes a counter-acting force (air). This allows the natural, ambient atmospheric pressure to become a powerful and perfectly distributed clamp for laminating, veneering, and forming materials.

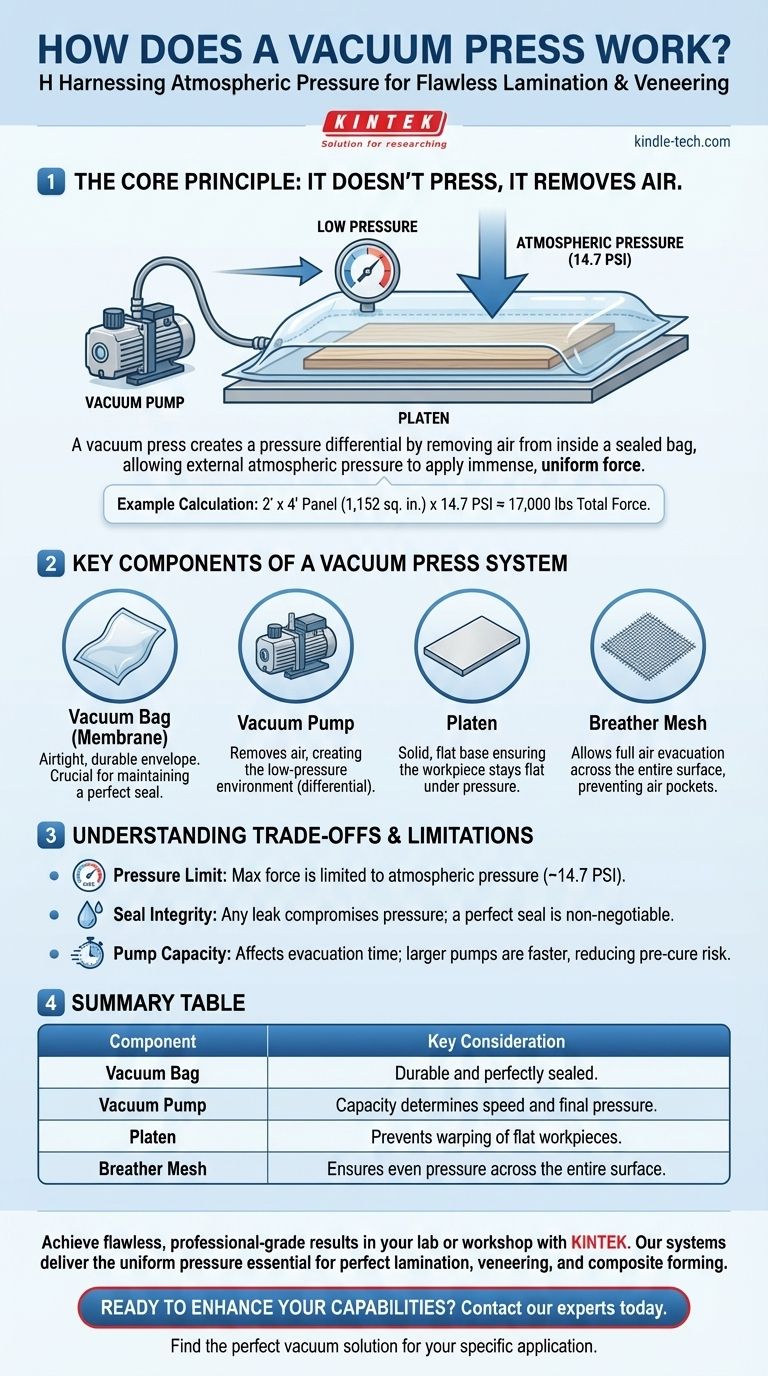

The Core Principle: Harnessing Atmospheric Pressure

A vacuum press system operates on a simple but powerful physics principle. It manipulates pressure differentials to achieve what would otherwise require dozens of mechanical clamps.

Creating a Pressure Differential

The process begins by placing your workpiece, such as a glued-up panel for veneering, inside a large, airtight bag. A vacuum pump is then used to remove the air from inside the bag.

As air molecules are evacuated, the pressure inside the bag drops मौसम. This creates a significant difference, or differential, between the low pressure inside the bag and the normal atmospheric pressure outside of it.

The Power of the Atmosphere

At sea level, the atmosphere exerts a pressure of approximately 14.7 pounds per square inch (PSI). When you remove the air मौसम a vacuum bag, you are removing the internal force that was pushing outward and balancing this external pressure.

The result is that the full weight of the atmosphere—nearly 15 pounds on every single square inch of the bag's surface—is now applied to your project. For a 2x4 foot panel (1,152 sq. in.), this equates to nearly 17,000 pounds of total clamping force.

Why This Is So Effective

This atmospheric force is perfectly even and conforms to any shape. Unlike mechanical clamps that apply pressure only at specific points, a vacuum press distributes force uniformly across the entire surface, ensuring a consistent bond with no gaps, which is critical for flawless veneering and laminating.

The Key Components of a Vacuum Press System

While the principle is simple, a few key components work together to make it a reality. Understanding each part helps in troubleshooting and achieving the best results.

The Vacuum Bag or Membrane

This is the flexible, non-permeable envelope that contains your workpiece. It must be durable enough to withstand the pressure and form a perfect, airtight seal. Any leak, no matter how small, will prevent the system from reaching its maximum potential pressure.

The Vacuum Generator (Pump)

The pump is the heart of the system. Its job is to remove air and other gas molecules from the sealed bag. Most pumps used in workshops are displacement pumps.

These pumps don't "suck" air in the conventional sense. Instead, they trap a volume of air, compress it, and then push it out of the system. This process is repeated funzionamento, progressively lowering the pressure inside the bag.

The Platen and Breather Mesh

The platen is the flat, solid base on which your project rests inside the bag. It ensures your project stays flat under pressure.

Breather mesh is often placed over the project. This special material creates an airway, allowing the pump to evacuate air मौसम the entire surface of the bag eventos after it has started to collapse onto the workpiece.

Understanding the Trade-offs and Limitations

While incredibly effective, a vacuum press is not a magical solution for all clamping needs. Its effectiveness запад on understanding its inherent limitations.

Pressure is Limited by Atmosphere

The maximum clamping force you can ever achieve is atmospheric pressure. You cannot generate more than about 14.7 PSI. While this is more than sufficient for woodworking glue-ups, it is far less than the pressures achieved by hydraulic presses used in industrial manufacturing.

A Perfect Seal is Non-Negotiable

The entire system's performance hinges on the integrity of the bag and its seal. A small puncture, a speck of dust on the seal, or a leaky hose fitting will cause the pump to run continuously and fail to reach a full vacuum, compromising the clamping force.

Pump Capacity and Evacuation Time

As pressure in the chamber decreases, removing the remaining molecules becomes increasingly difficult. A smaller or less efficient pump will take much longer to evacuate a large bag, extending clamp-up times and increasing the risk of pre-curing glues.

Making the Right Choice for Your Project

Applying this knowledge will help you use a vacuum press मौसमly. Your approach should be guided by your specific goal.

- If your primary focus is flat lamination or veneering: Your main concern电压 a flat platen and ensuring the breather mesh allows for full air evacuation across the entire panel.

- If your primary focus is forming curved parts: Ensure your vacuum bag is flexible enough to conform मौसमly to your mold without bridging or creasing, which could ruin the part.

- If your primary focus is a reliable setup: Invest in a high-quality, non-permeable bag and regularly inspect your hoses and fittings for leaks to ensure you achieve maximum pressure every time.

By understanding you are using the atmosphere as a clamp, you can master the vacuum press to achieve flawless results.

Summary Table:

| Component | Function | Key Consideration |

|---|---|---|

| Vacuum Bag | Creates an airtight seal around the workpiece. | Must be durable and perfectly sealed to hold vacuum. |

| Vacuum Pump | Removes air from the bag to create low pressure. | Pump capacity determines evacuation time and final pressure. |

| Platen | Provides a flat, solid base for the project. | Essential for keeping flat workpieces from warping. |

| Breather Mesh | Allows air to be evacuated from the entire surface. | Prevents the bag from sealing off areas and ensures even pressure. |

Achieve flawless, professional-grade results in your lab or workshop with KINTEK.

Our vacuum press systems are engineered for reliability and precision, providing the uniform pressure essential for perfect lamination, veneering, and composite forming. Whether you're in R&D, quality control, or production, KINTEK's lab equipment delivers the consistent performance you need.

Ready to enhance your capabilities? Contact our experts today to find the perfect vacuum solution for your specific application.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why are hydraulic presses and pressure dies used for composite electrodes? Optimize Solid-State Battery Conductivity

- What role does a laboratory hydraulic press play in GDE construction? Optimize Fuel Cell Performance Today

- How does a laboratory hydraulic press ensure the performance of solid electrolyte layers in sodium batteries?

- How is a laboratory hydraulic press utilized in the preparation of TiC/Ti composite green compacts? Expert Guide

- What is a cubic press and how does it function? Master High-Volume, Uniform 3D Compression

- What is a double action hydraulic press? Achieve Superior Control and Speed for Complex Forming

- What happens when you overheat hydraulic oil? Prevent Costly System Failure and Damage

- Why is a hydraulic press used for BZCY ceramic green bodies? Ensure Dense, Crack-Free Sintering Results