When preserving biological materials, freeze drying is a fundamentally superior method for achieving long-term, shelf-stable preservation. Unlike conventional freezing which merely suspends biological activity by turning water into potentially damaging ice, freeze drying (lyophilization) removes the water entirely. This process preserves the material's physical and biological structure while eliminating the need for a constant, energy-intensive cold chain.

The core distinction is not about temperature, but about the state of water. Conventional freezing manages existing ice crystals, which can compromise sample integrity. Freeze drying removes these crystals altogether, resulting in a lightweight, structurally intact product that is stable at room temperature.

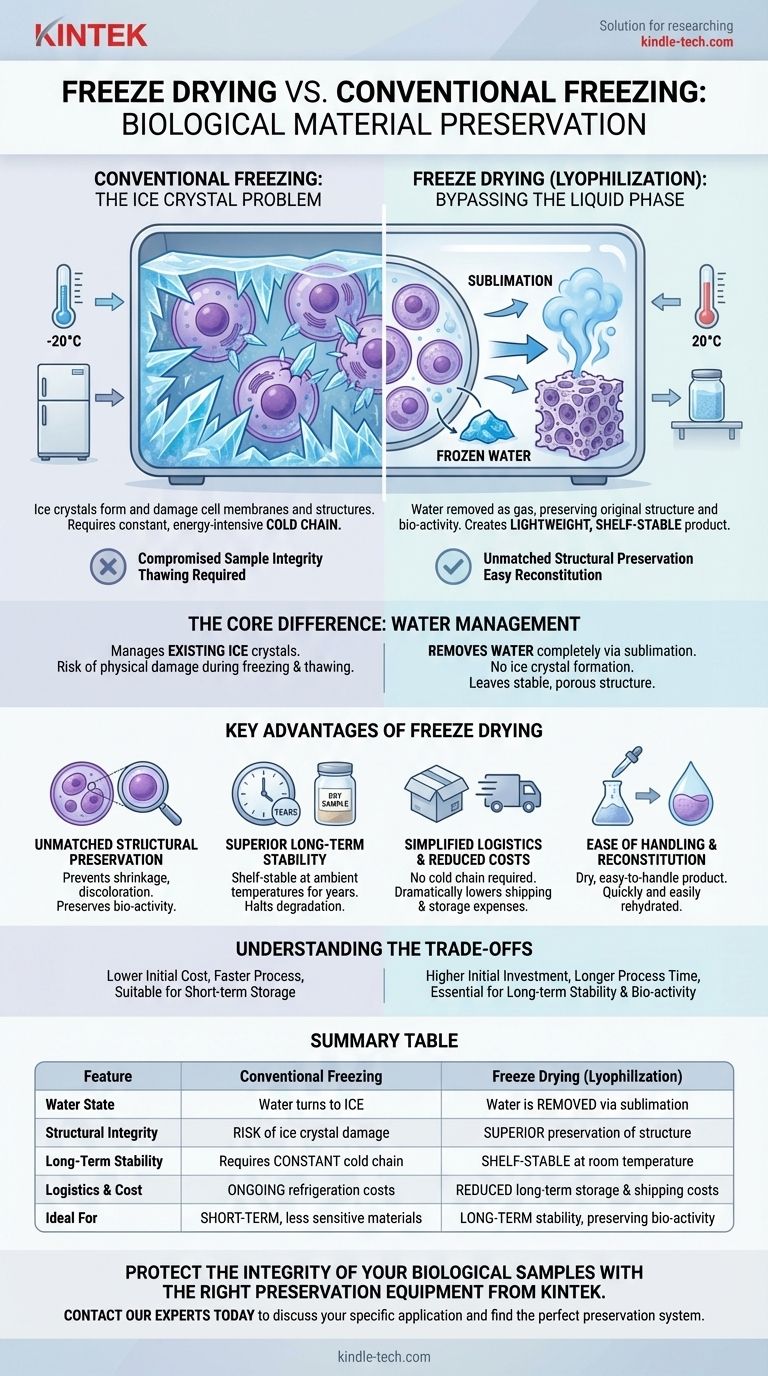

The Core Difference: Managing Water and Ice

The method you choose has a direct impact on the microscopic structure of your biological samples. The key variable is how each process handles the water contained within the cells.

Conventional Freezing: The Ice Crystal Problem

Conventional freezing simply lowers the temperature until the water inside the material becomes solid ice.

While this effectively halts most biological and chemical degradation, the formation of ice crystals can cause significant physical damage. These sharp crystals can puncture cell membranes and disrupt the delicate architecture of proteins and other molecules.

This damage becomes especially pronounced during thawing, limiting the sample's viability for many sensitive applications.

Freeze Drying (Lyophilization): Bypassing the Liquid Phase

Freeze drying is a more sophisticated, three-step process designed to remove water without causing structural damage.

The material is first frozen solid. It is then placed under a deep vacuum, and a small amount of heat is applied. This causes the frozen water to turn directly from a solid into a gas in a process called sublimation, completely bypassing the damaging liquid phase.

By removing the water molecules themselves, you are left with a structurally sound, porous scaffold of the original material.

Key Advantages of Freeze Drying

The sublimation process creates several distinct advantages over simply keeping a sample frozen, especially when long-term stability and integrity are priorities.

Unmatched Structural Preservation

Because water is removed as a gas, the material's original shape, size, and structure are left intact.

This prevents the shrinkage, discoloration, and loss of texture common in other drying methods. For pharmaceuticals, enzymes, or microbial cultures, this means preserving the very structure that dictates their biological activity.

Superior Long-Term Stability

Water is the medium for most biochemical reactions that lead to degradation. By removing over 95% of the water, freeze drying effectively halts these processes.

This makes the material shelf-stable at ambient temperatures for years, eliminating the risk and expense associated with freezer failure or cold chain disruptions during transport.

Simplified Logistics and Reduced Costs

Freeze-dried materials are lightweight and do not require ongoing refrigeration.

This dramatically reduces shipping and storage costs. It breaks the dependency on an unbroken "cold chain," which is a major logistical and financial burden for distributing sensitive biological products globally.

Ease of Handling and Reconstitution

The final product is a dry, often porous solid or powder that is easy to handle, measure, and store. It can be quickly and easily rehydrated, often returning to a state nearly identical to its pre-frozen condition.

Understanding the Trade-offs

While freeze drying offers superior results, it is not always the necessary choice. Its advantages come with specific operational considerations.

The Initial Investment

Freeze dryers are complex pieces of equipment that represent a significantly higher capital investment than conventional laboratory freezers. The process requires precise control over temperature and vacuum.

Process Time and Energy

A typical freeze-drying cycle can take many hours, or even days, to complete. While it saves energy on long-term storage and transport, the process itself is more energy-intensive than simply placing a sample in a freezer.

When "Good Enough" is Right

For many routine applications involving short-term storage or less sensitive materials, conventional freezing is perfectly adequate. If you have a reliable cold chain and are not concerned about minor ice crystal damage, the simplicity and speed of freezing may be the more practical option.

Making the Right Choice for Your Goal

Your choice depends entirely on your priorities for sample integrity, storage duration, and operational complexity.

- If your primary focus is long-term stability and preserving bio-activity: Freeze drying is the definitive choice for creating shelf-stable samples that do not require a cold chain.

- If your primary focus is short-term preservation or cost-sensitive operations: Conventional freezing is a fast, simple, and effective method, provided you can maintain an unbroken cold chain.

Ultimately, investing in the right preservation method protects the integrity of your material and the validity of your future work.

Summary Table:

| Feature | Conventional Freezing | Freeze Drying (Lyophilization) |

|---|---|---|

| Water State | Water turns to ice | Water is removed via sublimation |

| Structural Integrity | Risk of ice crystal damage | Superior preservation of structure |

| Long-Term Stability | Requires constant cold chain | Shelf-stable at room temperature |

| Logistics & Cost | Ongoing refrigeration costs | Reduced long-term storage & shipping costs |

| Ideal For | Short-term preservation, less sensitive materials | Long-term stability, preserving bio-activity |

Protect the integrity of your biological samples with the right preservation equipment from KINTEK.

Whether your lab requires reliable conventional freezers for short-term storage or advanced freeze dryers for creating shelf-stable, long-term samples, KINTEK has the solution. We specialize in high-quality lab equipment and consumables to meet all your laboratory preservation needs.

Contact our experts today to discuss your specific application and find the perfect preservation system to ensure the validity of your work.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Hybrid Tissue Grinding Mill

- Small Injection Molding Machine for Lab Use

People Also Ask

- In which fields is the laboratory freeze dryer commonly used? Essential for Biopharma, Food Science & Research

- What are the overall benefits of freeze drying technology across industries? Achieve Unparalleled Product Preservation

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- How does freeze drying support lab research? Preserve Samples with Perfect Fidelity

- What is the significance of freeze dryers in biotechnology? Preserving Life-Saving Samples for Research