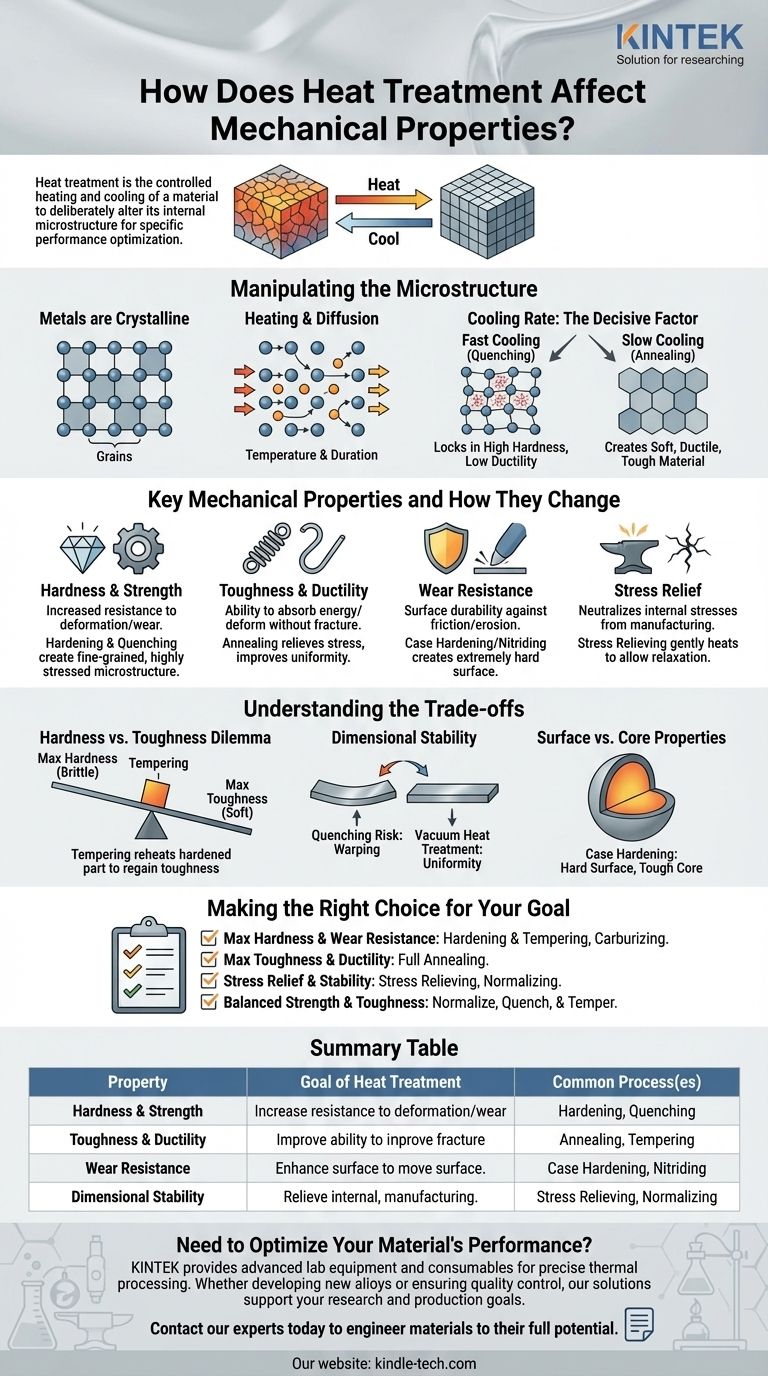

At its core, heat treatment is the controlled process of heating and cooling a material, most often a metal alloy, to deliberately alter its internal microstructure. This manipulation is not arbitrary; it is a precise engineering discipline used to enhance or suppress specific mechanical properties. By changing the atomic arrangement within the material, you can transform a soft, workable metal into a hard, wear-resistant component, or relieve internal stresses to prevent future failure.

Heat treatment is not about making a material "better" in all aspects, but about strategically optimizing its performance for a specific application. By controlling the material's microscopic crystal structure, you can trade one property (like softness) for another (like hardness) to achieve the ideal balance of strength, toughness, and durability.

The Goal: Manipulating the Microstructure

To understand how heat treatment works, you must first understand that a material's bulk properties are dictated by its internal, microscopic structure.

Why Microstructure Matters

Metals are crystalline, meaning their atoms are arranged in a highly organized, repeating pattern called a lattice. These lattices form "grains." The size, shape, arrangement, and composition of these grains—the material's microstructure—directly determine its mechanical properties.

The Role of Temperature and Diffusion

Heating a metal provides the energy needed for atoms to move, or diffuse, within the crystal lattice. This allows elements within an alloy (like carbon in steel) to dissolve and distribute more evenly, creating a new, uniform solid-state solution. The temperature and duration of the heating cycle determine the extent of this change.

Cooling Rate: The Decisive Factor

The rate at which the metal is cooled from its high-temperature state is the most critical factor. The cooling rate "locks in" a specific microstructure, which in turn defines the final mechanical properties.

- Fast cooling (quenching) traps atoms in a highly strained, distorted lattice, resulting in high hardness and strength but low ductility.

- Slow cooling (annealing) gives atoms time to rearrange into a more stable, stress-free structure, resulting in a softer, more ductile, and tougher material.

Key Mechanical Properties and How They Change

Different heat treatment processes are designed to target and optimize specific properties based on the intended use of the component.

Hardness and Strength

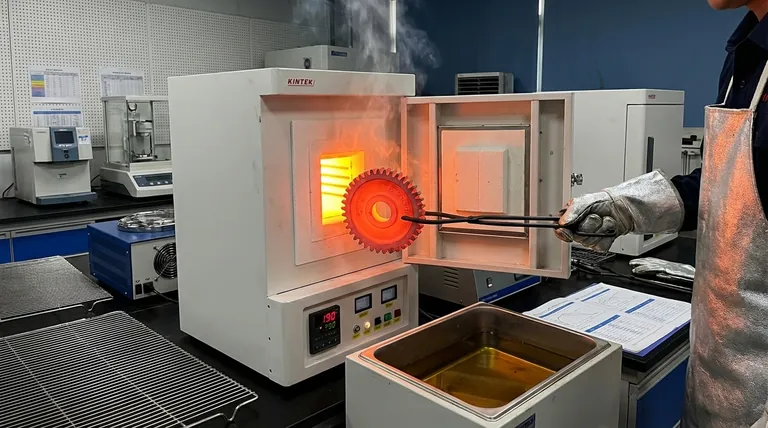

Hardness (resistance to indentation and scratching) and strength (resistance to deformation) are often increased together. Processes like hardening involve heating the metal and then rapidly quenching it in water, oil, or air. This creates a fine-grained, highly stressed microstructure that strongly resists external forces.

Toughness and Ductility

Toughness is a material's ability to absorb energy and deform without fracturing, while ductility is its ability to be stretched or drawn into a wire. Processes like annealing (heating and cooling very slowly) relieve internal stresses and create a more uniform grain structure, significantly improving both toughness and ductility at the expense of hardness.

Wear Resistance

Wear resistance is directly related to hardness. By creating an extremely hard surface through processes like case hardening or nitriding, a component can withstand abrasion, friction, and erosion far better. This is critical for parts like gears, bearings, and cutting tools.

Stress Relief

Manufacturing processes like welding, machining, or cold forming introduce significant internal stresses into a material. If left untreated, these stresses can lead to warping, distortion, or premature cracking. A low-temperature heat treatment known as stress relieving gently heats the part to allow the microstructure to relax, neutralizing these internal forces without significantly altering other properties.

Understanding the Trade-offs

Improving one mechanical property often comes at the expense of another. A skilled engineer must understand and manage these trade-offs.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in heat treatment. A material that has been quenched to its maximum hardness is also extremely brittle and has very low toughness.

To solve this, a secondary process called tempering is used. The hardened part is reheated to a lower temperature, which relieves some of the internal strain and sacrifices a small amount of hardness to regain a significant amount of toughness.

Dimensional Stability and Distortion

The rapid temperature changes involved in heat treatment, especially quenching, can cause a part to warp, distort, or even crack. This risk is highest in complex geometries or thin-walled components.

Techniques like vacuum heat treatment minimize this by providing uniform heating and preventing surface oxidation, which can contribute to uneven cooling. For high-precision parts, slower cooling rates or specialized press quenching may be required.

Surface vs. Core Properties

For many applications, you need a combination of properties: a very hard, wear-resistant surface and a tough, ductile core that can withstand impact.

Case hardening (or surface hardening) achieves this by introducing elements like carbon or nitrogen into only the surface layer of the metal. When the part is heat-treated, only the case becomes hard, while the core retains its original toughness.

Making the Right Choice for Your Goal

Selecting the correct heat treatment requires a clear understanding of the final application's primary requirement.

- If your primary focus is maximum hardness and wear resistance: Use a hardening and tempering cycle, or a surface hardening process like carburizing or nitriding.

- If your primary focus is maximum toughness and ductility: Use a full annealing process to create the softest, most workable state.

- If your primary focus is relieving stress to improve stability and machinability: Use a stress-relieving or normalizing heat treatment.

- If your primary focus is a balanced combination of strength and toughness: A normalize, quench, and temper cycle is the most common and versatile approach for structural components.

Ultimately, mastering heat treatment means understanding it not as a single action, but as a powerful tool for engineering a material to its full potential.

Summary Table:

| Property | Goal of Heat Treatment | Common Process(es) |

|---|---|---|

| Hardness & Strength | Increase resistance to deformation and wear | Hardening, Quenching |

| Toughness & Ductility | Improve ability to absorb energy and deform without cracking | Annealing, Tempering |

| Wear Resistance | Enhance surface durability against abrasion | Case Hardening, Nitriding |

| Dimensional Stability | Relieve internal stresses to prevent warping | Stress Relieving, Normalizing |

Need to Optimize Your Material's Performance?

Choosing the right heat treatment process is critical for achieving the perfect balance of strength, toughness, and durability in your components. KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise thermal processing and material analysis.

Whether you are developing new alloys or ensuring quality control in manufacturing, our solutions support your research and production goals. Contact our experts today to discuss how we can help you engineer materials to their full potential.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Does heat treatment affect conductivity? Mastering Material Properties for Performance

- What are the 3 types of biomass? A Guide to Woody, Agricultural, and Waste Sources

- Can sintered parts be machined? How to Overcome the Challenges of Porosity

- What are the advantages of plastic pyrolysis process? Unlock Value from Waste Plastic

- What is the HIP process of metal? Achieve Perfect Density for Critical Components

- How long does vacuum casting take? A Detailed Breakdown of the 7-10 Day Timeline

- What is sputter coating in SEM? Essential Guide to Preventing Charging and Enhancing Image Quality

- What is a metal test called? A Guide to Heavy Metals Panels and Toxic Exposure Testing