In chemical analysis, the mixed melting point technique is a simple and rapid method used to confirm the identity of a solid compound. By mixing an unknown substance with a known, pure standard and measuring the melting point of the mixture, you can determine if the two are the same compound.

The core principle is melting point depression: When two different compounds are mixed, the mixture will typically melt at a lower and broader temperature range than either pure compound. If the compounds are identical, the melting point will remain sharp and unchanged.

The Principle Behind the Technique

To understand how this method works, you first need to grasp the relationship between purity and a substance's melting point.

The Purity of a Crystal Lattice

A pure crystalline solid has a highly ordered, repeating three-dimensional structure called a crystal lattice.

The intermolecular forces holding this structure together are uniform and strong. Overcoming these forces to break the lattice and melt the solid requires a specific, consistent amount of energy, which corresponds to a sharp and narrow melting point range.

How Impurities Cause Disruption

Introducing a different compound—an impurity—disrupts this perfect, repeating structure.

These foreign molecules get in the way, creating defects and weakening the intermolecular forces that hold the lattice together.

Melting Point Depression Explained

Because the forces holding the impure solid together are weaker, less energy is required to break them.

This results in two observable effects:

- Depression: The melting point of the mixture is lower than that of the pure substance.

- Broadening: The melting process occurs over a wider range of temperatures because the disruptions are not uniform throughout the crystal.

This phenomenon is a colligative property, meaning it depends on the number of solute (impurity) particles, not their chemical identity.

Performing a Mixed Melting Point Analysis

The practical application of this principle is straightforward and follows a clear, logical process.

Step 1: Characterize Your Unknown

First, carefully measure the melting point of your unknown compound by itself. This gives you a baseline value and an initial indication of its purity. A sharp melting range (e.g., 1-2°C) suggests a relatively pure substance.

Step 2: Select a Known Standard

Based on the measured melting point and any other available data (e.g., experimental context), choose a known, pure compound that you suspect might be your unknown. The known compound's literature melting point should be very close to what you measured.

Step 3: Create and Analyze the Mixture

Thoroughly grind together a small amount of your unknown compound with the known standard, typically in a 1:1 ratio.

Load this mixture into a capillary tube and measure its melting point using the same technique you used for the unknown alone.

Step 4: Interpret the Results

The outcome of this final measurement is what provides the identification.

- If the compounds are different, the known compound acts as an impurity for the unknown (and vice versa). You will observe a significant depression and broadening of the melting point.

- If the compounds are identical, no impurity has been introduced. The melting point of the mixture will be sharp and virtually identical to the melting points of the individual substances.

Common Pitfalls and Limitations

While powerful, the mixed melting point technique is not infallible. Objectivity requires understanding its limitations.

The Eutectic Point Exception

For some pairs of compounds, there exists a specific ratio called the eutectic mixture. This unique mixture melts at a sharp, constant temperature that is lower than the melting point of either pure component.

While the melting point is still depressed (indicating different compounds), its sharpness can be misleading if not interpreted carefully.

Incorrect Sample Ratios

Using a ratio far from 1:1, such as 9:1, may not introduce enough of the "impurity" to cause a clearly observable melting point depression. A 1:1 mixture maximizes the disruptive effect.

Procedural Errors

Inaccurate results can arise from common laboratory errors. These include heating the sample too quickly, poor packing of the capillary tube, or inaccurate thermometer readings. Consistency in technique is critical.

Limited Scope of Identification

This technique can only provide strong evidence that two compounds are the same. It cannot, on its own, definitively identify a complete unknown without a candidate standard to test against.

Making the Right Choice for Your Goal

Use this technique as a powerful piece of evidence in your broader analysis.

- If your primary focus is confirming a reaction product: Mix your synthesized product with a pure sample of the expected compound. An unchanged melting point provides strong evidence of success.

- If your primary focus is identifying an unknown substance: First, accurately determine its melting point. Then, use this technique to systematically test it against known compounds that have a similar melting point until you find a match.

Ultimately, the mixed melting point technique is an elegant diagnostic tool that leverages a fundamental physical property to bring clarity to chemical identity.

Summary Table:

| Scenario | Mixture Melting Point | Interpretation |

|---|---|---|

| Compounds are identical | Sharp, unchanged | Confirms identity |

| Compounds are different | Depressed, broad | Indicates different substances |

| Eutectic mixture | Sharp but depressed | Special case indicating different compounds |

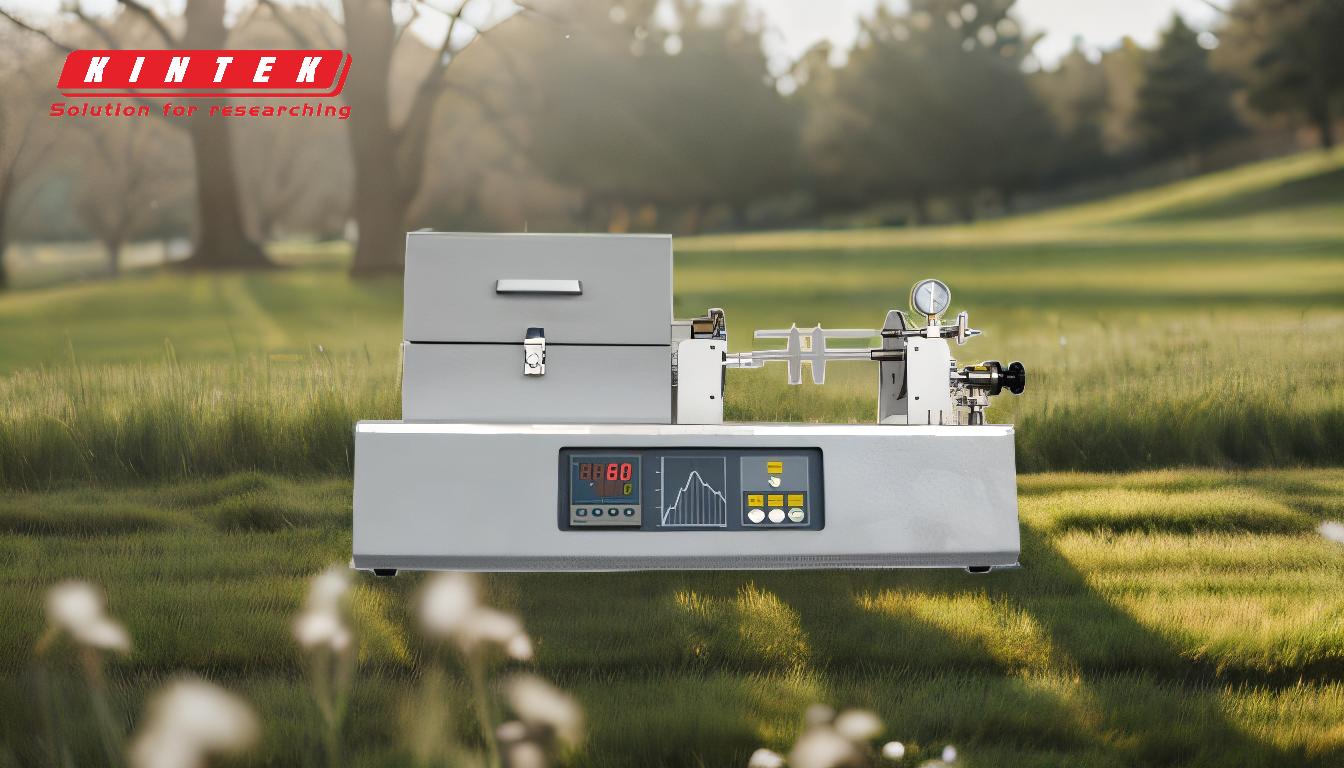

Need precise identification for your lab samples? KINTEK specializes in high-quality lab equipment and consumables that ensure accurate melting point determination and reliable results. Let our expertise support your chemical analysis workflows. Contact our team today to find the right tools for your laboratory needs!

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Isostatic Molding Pressing Molds for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

People Also Ask

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the process of VIM metal? Achieve Superior Purity for High-Performance Alloys

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What are the different melting methods? A Guide to Choosing the Right Industrial Furnace

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting