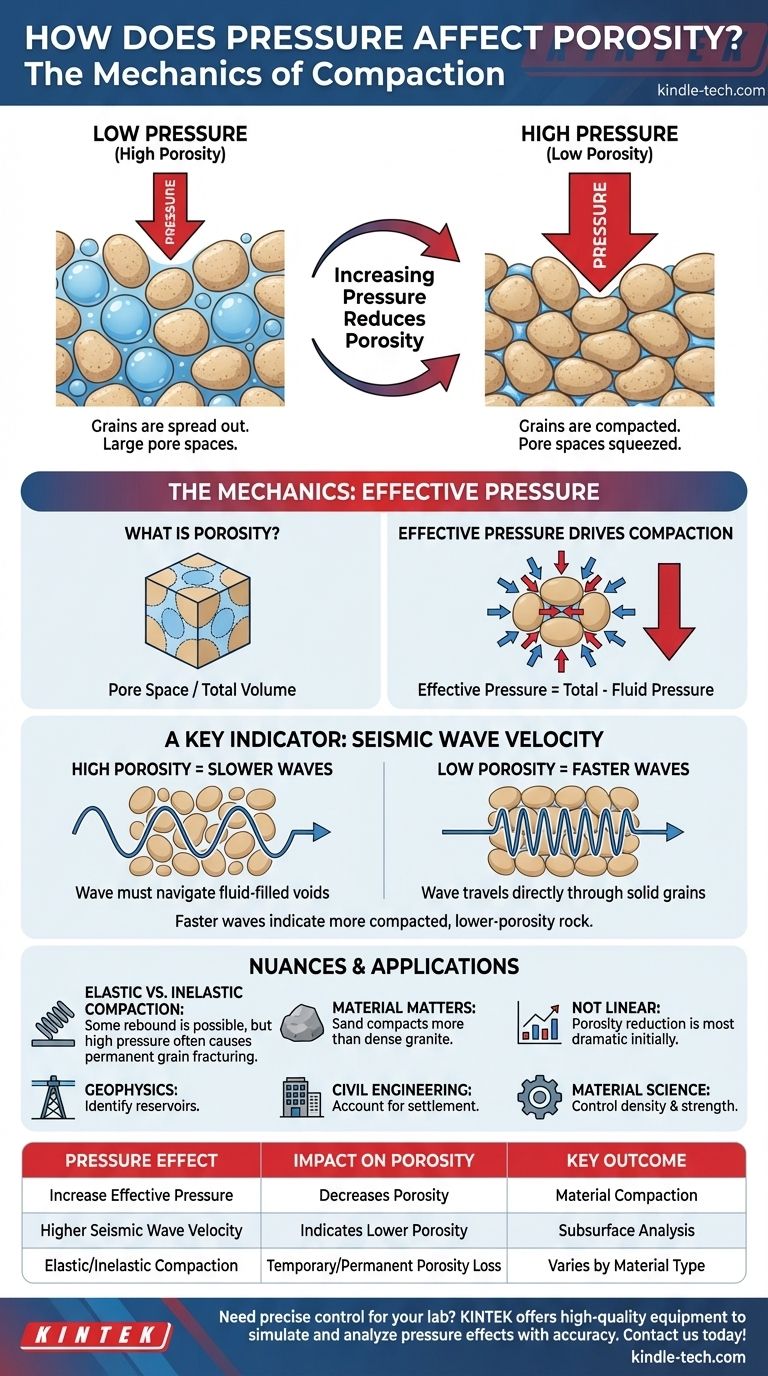

In short, increasing pressure on a porous material reduces its porosity. As the effective pressure rises, the solid grains that make up the material are forced closer together. This physical compaction squeezes the empty pore spaces, decreasing the overall volume of voids and thus lowering the material's porosity.

The relationship between pressure and porosity is fundamentally inverse. This isn't just a theoretical concept; it is the core principle that explains how geological formations compress, how soils settle under buildings, and how we can use seismic waves to interpret the world beneath our feet.

The Mechanics of Porosity Reduction

To grasp the full picture, it's essential to understand the forces at play and how they alter the physical structure of a material. This process is driven by what is known as "effective pressure."

What is Porosity?

Porosity is simply a measure of the empty, or void, spaces within a material. It is expressed as a percentage or a fraction of the total volume that is not occupied by solid matter.

The Critical Role of Effective Pressure

The key driver is effective pressure, not total pressure. This is the stress that is supported by the solid framework of the material at the points where grains make contact.

Imagine a water-filled sponge. The total pressure is the external force squeezing it. The fluid pressure is the water inside pushing back. Effective pressure is the net force that actually compresses the sponge's structure.

The Process of Compaction

As effective pressure increases, the grains of the material undergo physical changes. They begin to repack into a tighter, more dense arrangement.

Under significant pressure, weaker or more angular grains can deform or even fracture. This process, known as compaction, permanently reduces the size and number of pore spaces.

A Key Indicator: Seismic Wave Velocity

We can observe the effects of this pressure-porosity relationship indirectly by measuring how waves travel through a material. This is a foundational technique in fields like geophysics.

The Connection: Pressure, Porosity, and Velocity

Compressional waves, such as the P-waves used in seismic surveys, are essentially sound waves. These waves travel significantly faster through solid rock than they do through the fluid (like water, oil, or gas) that fills the pores.

An Inverse Relationship

When porosity is high, a wave must navigate through more of the "slower" fluid-filled voids, resulting in a lower overall velocity.

As pressure increases and porosity decreases, the material becomes more compact and solid. The wave can then travel more directly through the faster grain-to-grain contacts, causing its measured velocity to increase.

Practical Application in Geoscience

This principle is the bedrock of seismic exploration. By analyzing the velocity of seismic waves sent deep into the earth, geoscientists can infer the porosity of subsurface rock layers. Faster wave travel times often indicate more compacted, lower-porosity rock.

Common Pitfalls and Nuances

While the inverse relationship is a powerful rule, it's important to recognize its limitations and the factors that can influence it.

The Relationship is Not Perfectly Linear

The reduction in porosity is often most dramatic under initial pressure increases. As the material becomes highly compacted, it takes much more pressure to achieve further small reductions in porosity.

Material Type is a Decisive Factor

Different materials respond differently to pressure. A loosely packed, unconsolidated sand will compact significantly more than a dense, crystalline igneous rock like granite, which has very low initial porosity.

Elastic vs. Inelastic Compaction

In some cases, if pressure is removed, a material's porosity can partially rebound—this is elastic compaction. More commonly, especially under high geological pressures, the grain rearrangement and fracturing are permanent, resulting in inelastic compaction.

Making the Right Choice for Your Goal

Understanding this relationship is critical for interpreting data and predicting material behavior across several disciplines.

- If your primary focus is geophysics or petroleum engineering: Use the inverse relationship between seismic velocity and porosity as a primary tool for identifying and characterizing subsurface reservoirs.

- If your primary focus is civil engineering or soil mechanics: Always account for compaction under load, as the pressure from a structure will reduce soil porosity and inevitably lead to ground settlement.

- If your primary focus is material science: Recognize that applying pressure is a fundamental method for reducing porosity to control the final density, strength, and permeability of manufactured materials.

Ultimately, grasping how pressure governs porosity is essential for predicting how any porous material will respond to the stress of its environment.

Summary Table:

| Pressure Effect | Impact on Porosity | Key Outcome |

|---|---|---|

| Increase in Effective Pressure | Decreases Porosity | Material Compaction |

| Higher Seismic Wave Velocity | Indicates Lower Porosity | Used in Subsurface Analysis |

| Elastic/Inelastic Compaction | Temporary/Permanent Porosity Loss | Varies by Material Type |

Need precise control over material porosity for your lab work? KINTEK specializes in high-quality lab equipment and consumables that help you simulate and analyze pressure effects with accuracy. Whether you're in geoscience, civil engineering, or materials research, our solutions ensure reliable data and efficient workflows. Contact us today to explore how our products can support your specific laboratory needs!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- What are the disadvantages of powder metallurgy? Key Limitations in Strength and Size

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- What is the process of isostatic graphite? A Guide to High-Performance, Uniform Material Creation