In short, tempering reduces hardness. This reduction is not a failure of the process but its entire purpose. Freshly hardened steel is often too brittle for practical use, and tempering is the controlled process of sacrificing some of that peak hardness to gain a critical increase in toughness and durability.

The core purpose of tempering is to relieve the immense internal stresses created during hardening. This process transforms the steel's brittle microstructure into a more ductile and tough one, making the material useful by trading a degree of hardness for a significant reduction in brittleness.

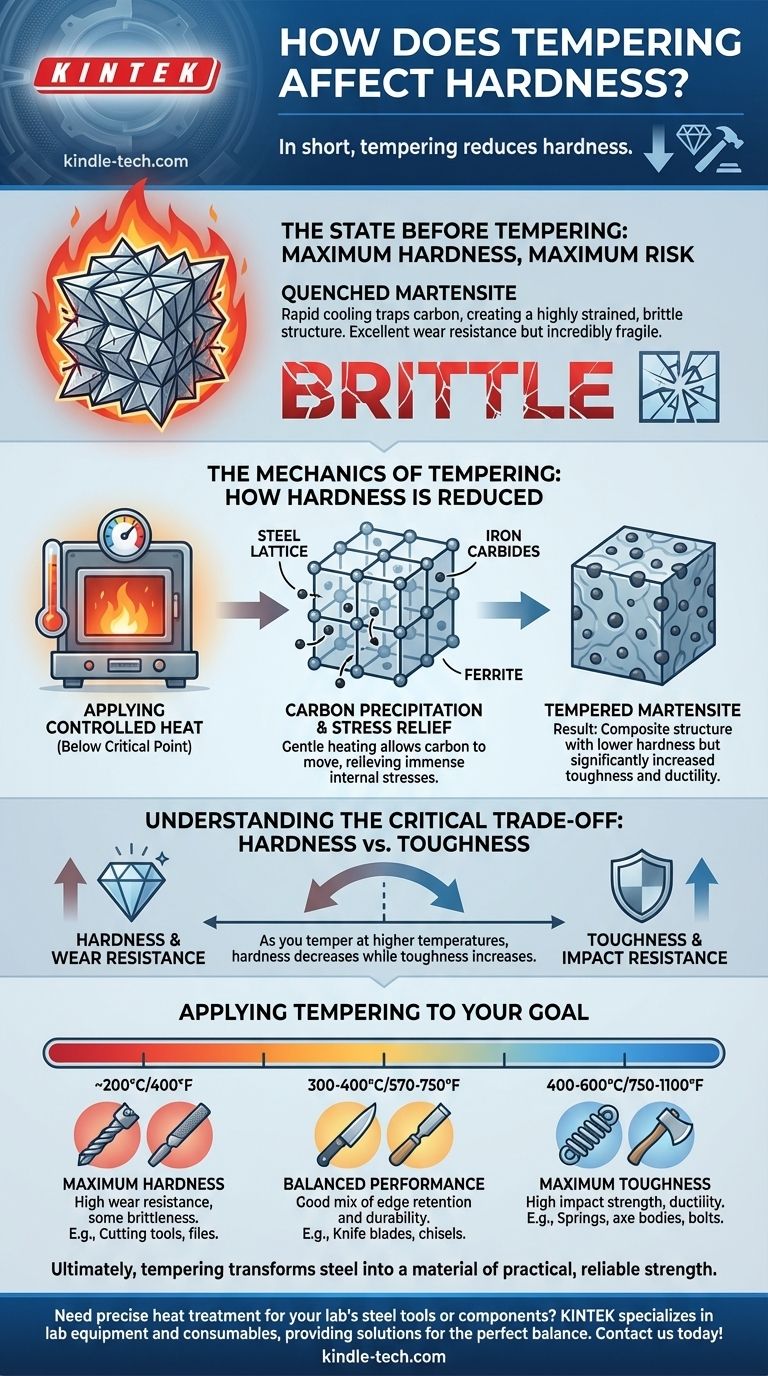

The State Before Tempering: Maximum Hardness, Maximum Risk

To understand tempering, you must first understand the state of steel immediately after it has been hardened. This sets the stage for why a reduction in hardness is not just desirable, but necessary.

The Quenching Process

Hardening begins by heating steel to a high temperature, causing its crystal structure to change into a phase called austenite. The steel is then rapidly cooled, or quenched, typically in water, oil, or air.

This extreme cooling shock doesn't give the crystal structure time to change back to its normal, soft state.

Introducing Martensite: The Brittle Giant

Instead, quenching traps carbon atoms within the iron crystal lattice, creating a new, highly strained microstructure called martensite.

Martensite is extremely hard and possesses excellent wear resistance. However, the internal stress makes it incredibly brittle, like glass. A sharp impact could cause it to shatter catastrophically.

The Mechanics of Tempering: How Hardness is Reduced

Tempering is a precise heat treatment process designed to carefully modify the unstable martensite structure.

Applying Controlled Heat

After quenching, the steel is reheated to a specific temperature below its critical point (well below the initial hardening temperature). This temperature is held for a set amount of time.

Carbon Precipitation and Stress Relief

This gentle heating gives the trapped carbon atoms enough energy to move. They migrate out of the strained martensite lattice and form tiny, distinct particles of very hard iron carbides (like cementite).

As the carbon leaves, the immense internal stress within the material is relieved. The crystal structure relaxes into a more stable and less-strained state.

The Result: Tempered Martensite

The resulting microstructure is a composite of a softer, more ductile iron matrix (ferrite) with many fine, hard carbide particles dispersed throughout. This is known as tempered martensite.

This new structure is no longer as hard as the original martensite, but it is substantially tougher and less brittle.

The Role of Temperature and Time

The final hardness is directly controlled by the tempering temperature.

A lower tempering temperature allows less carbon to move, resulting in a material that is still very hard but with some of the extreme brittleness removed.

A higher tempering temperature allows more carbon to migrate and form larger carbides, leading to a significant reduction in hardness but a dramatic increase in toughness.

Understanding the Critical Trade-off: Hardness vs. Toughness

The relationship between hardness and toughness in tempering is the central concept for any application. They exist in an inverse relationship.

Hardness and Wear Resistance

Hardness is a material's ability to resist scratching, abrasion, and indentation. A harder steel will hold a sharp edge longer and resist being worn away. Untempered martensite is at the peak of hardness.

Toughness and Impact Resistance

Toughness is a material's ability to absorb energy and deform without fracturing. A tough material can withstand sudden shocks, impacts, and bending forces. Tempering is the primary method for increasing toughness.

The Inverse Relationship

As a rule, when you temper steel at a higher temperature, its hardness and wear resistance decrease, while its toughness and ductility increase. The goal is to find the perfect balance point on this spectrum for the component's intended job.

Applying Tempering to Your Goal

The correct tempering temperature is dictated entirely by the final application of the steel component.

- If your primary focus is maximum hardness and wear resistance (e.g., cutting tools, files): Opt for a low tempering temperature (around 200°C / 400°F) to retain as much hardness as possible while relieving only the most extreme stresses.

- If your primary focus is maximum toughness and impact strength (e.g., springs, axe bodies, structural bolts): Use a higher tempering temperature (400-600°C / 750-1100°F) to significantly increase ductility and the ability to absorb shock.

- If you need a balance of edge retention and durability (e.g., knife blades, chisels): Select a mid-range temperature that provides a compromise, often identified visually by temper colors like straw yellow or blue.

Ultimately, tempering transforms steel from a material of pure potential into one of practical, reliable strength.

Summary Table:

| Tempering Goal | Typical Temperature Range | Resulting Properties | Common Applications |

|---|---|---|---|

| Maximum Hardness | ~200°C / 400°F | High wear resistance, some brittleness reduced | Cutting tools, files |

| Balanced Performance | 300-400°C / 570-750°F | Good mix of hardness and toughness | Knife blades, chisels |

| Maximum Toughness | 400-600°C / 750-1100°F | High impact strength, ductility | Springs, axe bodies, bolts |

Need precise heat treatment for your lab's steel tools or components? KINTEK specializes in lab equipment and consumables, providing solutions that ensure your materials achieve the perfect balance of hardness and toughness. Our expertise helps laboratories maintain optimal performance and durability for all their steel applications. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Does tempering steel increase hardness? Discover the Essential Trade-off for Toughness

- What are batch furnaces best used for? Maximize Flexibility in Heat Treatment & R&D

- What is the principle of muffle furnace in lab? Ensuring Sample Purity Through Complete Isolation

- What is the design and construction of a muffle furnace? A Guide to Its Isolated Heating Chamber

- What is the function of a high-temperature muffle furnace in YAG synthesis? Master Pure-Phase Crystal Production

- What function does a muffle furnace serve in catalyst activation? Unlock Optimal Zr-Mo Performance

- What is the main function of a muffle furnace? Achieve Pure, High-Temperature Processing

- What is powder sintering process? A Guide to Solid-State Metal & Ceramic Fabrication