While there is no single "too hot" temperature for all hydraulic systems, the widely accepted operational limit is 180°F (82°C). Exceeding this threshold is a critical warning sign, as it marks the point where most mineral-based hydraulic oils begin to rapidly degrade. The true maximum temperature is ultimately defined by the specific oil type, its additive package, and the temperature tolerance of the system's seals and hoses.

The core issue isn't a specific number on a thermometer; it's the irreversible damage that excessive heat inflicts on the hydraulic fluid itself. Heat destroys the oil's ability to lubricate and protect, triggering a cascade of failures that will shorten the life of every component in your system.

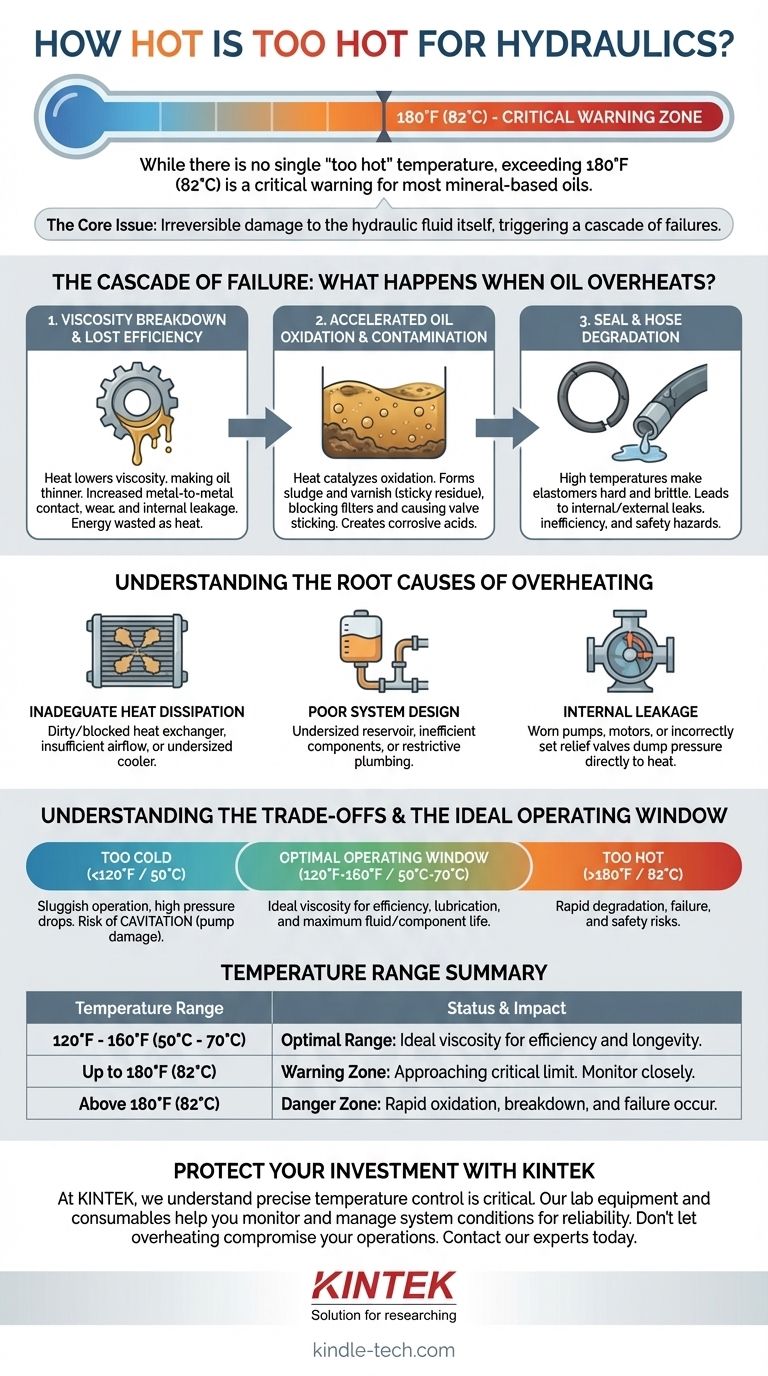

The Cascade of Failure: What Happens When Oil Overheats?

An overheating hydraulic system is not a minor issue; it is an active failure in progress. The heat initiates a chain reaction of degradation that compromises the entire system.

Viscosity Breakdown and Lost Efficiency

Heat drastically lowers the oil's viscosity, making it thinner. This thin fluid film is less effective at lubricating the tight tolerances inside pumps, motors, and valves.

The result is increased metal-to-metal contact, accelerated wear, and higher internal leakage. As fluid bypasses components internally, the system loses efficiency, meaning more energy is converted into waste heat instead of useful work.

Accelerated Oil Oxidation and Contamination

Heat acts as a catalyst for oxidation, a chemical reaction between the oil and oxygen. This process breaks down the oil, forming damaging byproducts.

These byproducts include sludge, which can block filters and small orifices, and varnish, a sticky residue that coats internal surfaces. Varnish can cause valves to stick and other precision components to malfunction. Oxidation also creates corrosive acids that attack metal surfaces and seals.

Seal and Hose Degradation

The elastomeric materials used for seals and hoses are highly susceptible to heat damage. High temperatures cause them to become hard, brittle, and lose their sealing capability.

This leads to both internal and external leaks. A leaking system is inefficient and poses a significant safety and environmental hazard.

Understanding the Root Causes of Overheating

To solve a heat problem, you must first diagnose its source. The heat in your system is a symptom of energy being wasted or improperly managed.

Inadequate Heat Dissipation

The most common cause is a failure to remove heat from the system. This is often due to a dirty or blocked heat exchanger (cooler), insufficient airflow across the cooler fins, or a cooler that is simply undersized for the system's heat load.

Poor System Design

System design plays a crucial role. An undersized reservoir doesn't allow the oil enough time to cool and release trapped air. Inefficient components or unnecessarily restrictive plumbing will generate excess heat during normal operation.

Internal Leakage

A worn component, such as a pump, motor, or incorrectly set relief valve, can cause high-pressure fluid to leak directly back to the reservoir without performing any work. This process converts all of the potential energy directly into heat, rapidly overwhelming the system's cooling capacity.

Understanding the Trade-offs

Managing temperature is a balancing act. The goal is not simply to run as cool as possible, but to maintain a stable temperature within the optimal range.

The Myth of "Cooler is Always Better"

Operating a hydraulic system too cold is also detrimental. Cold oil has a very high viscosity, which can lead to sluggish actuator movement and increased pressure drops.

More dangerously, thick, cold oil can starve the pump of fluid, a condition known as cavitation, which can destroy a pump in minutes.

The Ideal Operating Window

For most industrial and mobile systems using standard mineral oil, the optimal operating temperature is between 120°F and 160°F (50°C and 70°C). Within this range, the fluid has an ideal viscosity to ensure efficient operation, proper lubrication, and maximum fluid life.

Cost vs. Longevity

Investing in a larger reservoir or a more efficient cooling system has an upfront cost. However, running a system hot to save on initial expense is a false economy that will be paid for many times over in premature component failures, unplanned downtime, and frequent oil changes.

How to Apply This to Your System

Your strategy for managing hydraulic temperature should be based on your operational priorities and environment.

- If your primary focus is maximum component life and reliability: Aim to maintain a stable operating temperature in the 120°F-160°F (50°C-70°C) range, well below the 180°F (82°C) alarm limit.

- If your primary focus is troubleshooting an overheating system: Start by inspecting the heat exchanger and fluid level, then use an infrared thermometer to find hot spots that could indicate severe internal leakage from a specific component.

- If your primary focus is designing or purchasing a new system: Ensure the cooling package is sized to handle the maximum continuous heat load, not just the average, and account for the highest ambient temperatures in your operating environment.

Ultimately, managing hydraulic temperature is about preserving the fluid's integrity to protect the entire system.

Summary Table:

| Temperature Range | Status & Impact |

|---|---|

| 120°F - 160°F (50°C - 70°C) | Optimal Range: Ideal viscosity for lubrication, efficiency, and maximum fluid/component life. |

| Up to 180°F (82°C) | Warning Zone: Approaching critical limit for most mineral oils. Monitor closely. |

| Above 180°F (82°C) | Danger Zone: Rapid oil oxidation, viscosity breakdown, and accelerated seal/hose failure occur. |

Is your hydraulic system running hot? Protect your investment and avoid costly downtime.

At KINTEK, we understand that precise temperature control is critical for laboratory and industrial hydraulic systems. Our range of high-quality lab equipment and consumables is designed to help you monitor and manage system conditions effectively, ensuring reliability and longevity.

Don't let overheating compromise your operations. Contact our experts today to discuss your specific needs and discover how KINTEK solutions can help you maintain optimal performance.

Visual Guide

Related Products

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- Shaking Incubators for Diverse Laboratory Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- Why is it necessary to equip corn cob hydrolysis systems with rapid cooling? Maximize Glucose and Xylose Yield

- Why are internal cooling coils used after hydrothermal treatment? Unlock Higher Yields in Biomass Processing

- What is the delta 20 rule? A Guide to Diagnosing and Perfecting Your Espresso

- Why is a high-performance cooling circulator necessary in silica membrane desalination? Boost Your Permeate Mass Transfer

- What is the purpose of using a cooling water system after wheat straw pretreatment? Optimize Sugar Yield and Safety