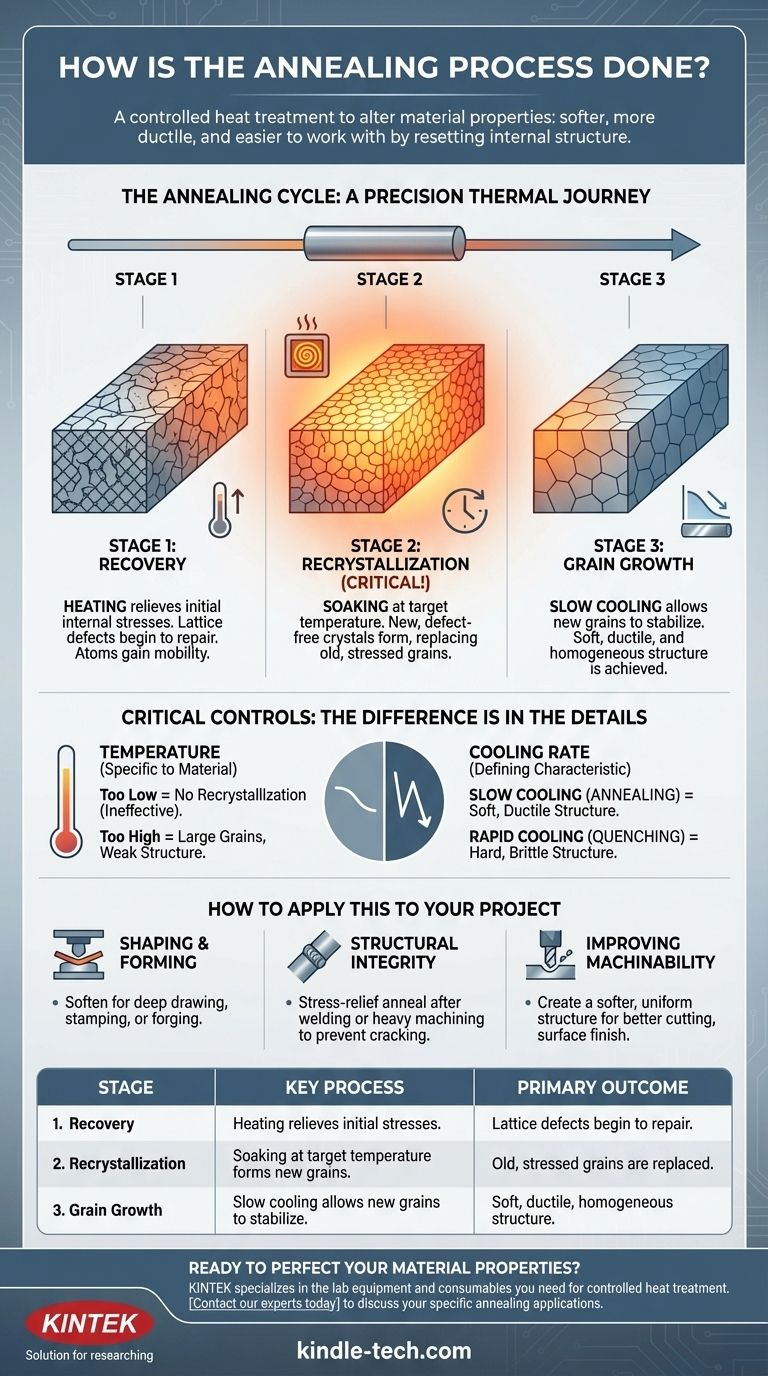

At its core, the annealing process is a controlled heat treatment used to alter a material's physical and sometimes chemical properties. It involves heating a metal or alloy to a specific temperature, holding it there for a set time, and then cooling it slowly. This procedure fundamentally makes the material softer, more ductile, and easier to work with by resetting its internal crystalline structure.

Annealing is not simply heating and cooling a material. It is a precise thermal cycle designed to relieve internal stresses, erase the effects of prior work, and produce a uniform microstructure, thereby making the material less brittle and more formable.

The Purpose of Annealing: Releasing Internal Stress

Many manufacturing processes, such as casting, welding, or cold working (like bending or stamping), introduce significant stress into a material's internal structure. This accumulated stress makes the material harder and more brittle, increasing the risk of cracking or failure under load.

Relieving Fabrication Stresses

Annealing is the primary method for relieving these internal stresses. By heating the material, you give its atoms enough energy to move and rearrange themselves into a more stable, lower-stress state.

Increasing Ductility and Toughness

A key goal of annealing is to increase ductility (the ability to be stretched or drawn without breaking) and toughness. This makes the material much easier to shape, machine, or form in subsequent manufacturing steps.

Creating a Homogeneous Structure

The process also helps to create a more uniform and consistent internal grain structure. This homogeneity ensures that the material's properties are predictable and reliable throughout the entire part.

The Three Stages of the Annealing Cycle

The transformation during annealing doesn't happen all at once. It occurs across three distinct, temperature-dependent stages.

Stage 1: Recovery

As the material is heated, the first stage is recovery. During this phase, the material begins to relieve internal stresses as the crystal lattice defects start to repair themselves. The atoms gain mobility but have not yet begun to form new crystal structures.

Stage 2: Recrystallization

This is the most critical stage. As the material reaches its target annealing temperature, recrystallization begins. New, defect-free crystals (or "grains") start to form and grow, completely replacing the old, deformed, and stressed grains from the material's previous state. The material is held at this temperature—a process called "soaking"—to ensure this transformation is complete.

Stage 3: Grain Growth

During the final, slow-cooling stage, these new grains can continue to grow. The rate of cooling is critical; it must be slow enough to allow the new, stress-free structure to stabilize properly without introducing new thermal stresses.

Understanding the Critical Controls

The success of annealing depends entirely on precise control over temperature and time. Deviating from the required parameters can lead to undesirable results or even ruin the material.

The Importance of Temperature

The annealing temperature is specific to each material. If the temperature is too low, recrystallization will not occur, and the process will be ineffective. If it's too high, the grains can grow too large, which can make the material weaker, or it could even begin to melt.

The Role of the Cooling Rate

The cooling rate is what distinguishes annealing from other heat treatments. Slow cooling is the defining characteristic of annealing, producing a soft and ductile state. In contrast, rapid cooling (quenching) would lock in a different crystal structure, making the material hard and brittle—a process known as hardening.

How to Apply This to Your Project

Your decision to use annealing should be based on the material's condition and your end goal.

- If your primary focus is preparing a material for significant shaping: Use annealing to soften a raw or work-hardened material, making it ductile enough for processes like deep drawing, stamping, or forging.

- If your primary focus is ensuring structural integrity after fabrication: Apply a stress-relief anneal after processes like welding or heavy machining to prevent delayed cracking and improve service life.

- If your primary focus is improving machinability: Anneal a hard or inconsistent material to create a softer, more uniform structure that is easier to cut, reducing tool wear and improving surface finish.

Ultimately, mastering annealing allows you to take control of a material's properties, transforming it to perfectly suit your specific application.

Summary Table:

| Stage | Key Process | Primary Outcome |

|---|---|---|

| 1. Recovery | Heating relieves initial internal stresses. | Lattice defects begin to repair. |

| 2. Recrystallization | Soaking at target temperature forms new grains. | Old, stressed grains are replaced. |

| 3. Grain Growth | Slow cooling allows new grains to stabilize. | Soft, ductile, and homogeneous structure is achieved. |

Ready to perfect your material properties with precise annealing?

KINTEK specializes in the lab equipment and consumables you need to achieve controlled heat treatment. Whether you're preparing materials for shaping, ensuring structural integrity after fabrication, or improving machinability, our solutions deliver the consistent results your laboratory requires.

Contact our experts today to discuss how we can support your specific annealing applications and enhance your lab's capabilities.

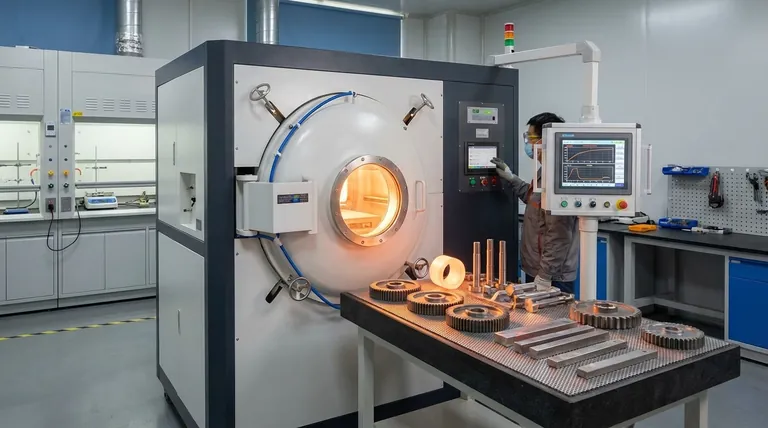

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is vacuum annealing? Achieve Clean, Oxide-Free Metal Parts for Superior Performance

- Which factor causes the failure of furnace lining? The primary cause is thermal stress and spalling.

- How does multi-stage vacuum distillation facilitate the removal of zinc and cadmium from crude magnesium?

- What is vacuum heat treatment? Achieve Superior Material Performance and Pristine Finishes

- Why is a preheating oven used to treat AISI 316L stainless steel? Ensure Integrity & Superior Salt Bath Nitriding

- What is a sintering machine? Transforming Powders into High-Performance Parts

- Why is a vacuum oven required for degassing carbon black in fluoride ion batteries? Ensure High-Purity Electrodes

- Why is a vacuum drying oven required for SiCw aluminum composites? Ensure Pure Powders for High-Strength Sintering