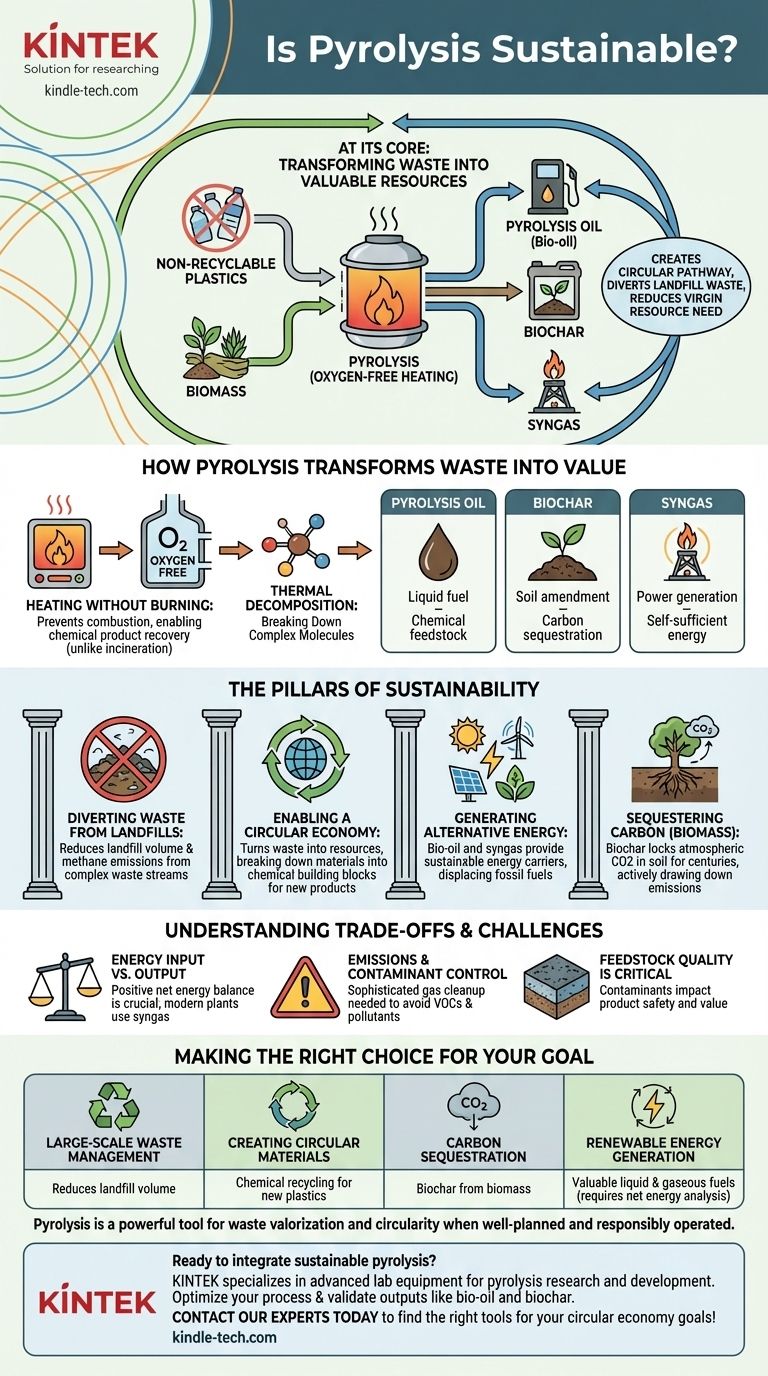

At its core, pyrolysis is considered sustainable because it is a thermochemical process that transforms waste materials, such as non-recyclable plastics and biomass, into valuable resources like fuel and chemicals. This method simultaneously diverts significant waste from landfills and creates a circular pathway for materials that would otherwise be discarded, reducing the need for virgin resource extraction.

The sustainability of any pyrolysis operation is not a given; it is a direct result of the specific feedstock used, the energy efficiency of the system, and how the resulting products are managed. When executed correctly, it is a powerful tool for waste valorization and circularity.

How Pyrolysis Transforms Waste into Value

Pyrolysis is fundamentally a process of thermal decomposition. It involves heating organic-based materials, such as plastics, tires, or agricultural biomass, to high temperatures in an environment completely devoid of oxygen.

The Core Process: Heating Without Burning

Unlike incineration, which burns waste with oxygen to produce heat and ash, pyrolysis uses heat to break down complex molecules into simpler, more valuable ones. The absence of oxygen is critical because it prevents combustion, allowing for the recovery of chemical products instead of just releasing energy as heat.

The Key Outputs: A Versatile Trio

The process typically yields three primary products, each with its own sustainable application:

- Pyrolysis Oil (Bio-oil): A liquid fuel similar to crude oil that can be refined into transportation fuels, used in boilers for heat and power, or serve as a chemical feedstock.

- Biochar (or Carbon Black): A stable, solid, carbon-rich material. When derived from biomass, biochar is a powerful soil amendment that improves water retention and sequesters carbon for centuries. When from tires or plastics, it can be used as a pigment or reinforcing agent.

- Syngas: A mixture of combustible gases (primarily hydrogen and carbon monoxide). This gas can be combusted on-site to provide the heat needed to power the pyrolysis reactor, making the process more self-sufficient.

The Pillars of Pyrolysis Sustainability

The sustainability argument for pyrolysis rests on its ability to address several key environmental challenges simultaneously.

Pillar 1: Diverting Waste from Landfills

Pyrolysis provides a viable solution for complex and often non-recyclable waste streams. This includes mixed plastics, used tires, and agricultural residues that would otherwise occupy vast amounts of landfill space, releasing methane—a potent greenhouse gas—as they decompose.

Pillar 2: Enabling a Circular Economy

The process exemplifies a core principle of the circular economy: turning waste into a resource. Pyrolysis breaks down materials like plastics into their basic chemical building blocks. These can then be used to create new plastics or other chemicals, reducing our reliance on fossil fuels for virgin material production.

Pillar 3: Generating Alternative Energy

Both the bio-oil and syngas produced are energy carriers. As mentioned in the reference, this provides a sustainable energy source. Using the syngas to power the facility reduces its external energy demand, while the bio-oil can displace fossil fuels in other industrial applications.

Pillar 4: Sequestering Carbon

When biomass is the feedstock, the creation of biochar represents a significant form of carbon removal. The carbon that the plant absorbed from the atmosphere is locked into the stable biochar. When added to soil, this carbon is effectively sequestered for hundreds or even thousands of years, actively drawing down atmospheric CO2.

Understanding the Trade-offs and Challenges

True sustainability requires an objective look at the potential downsides. Pyrolysis is a sophisticated industrial process with challenges that must be managed responsibly.

Energy Input vs. Energy Output

A pyrolysis facility requires a significant initial energy input to reach operating temperature. A system is only truly sustainable if its net energy balance is positive—meaning it produces more energy in its outputs than it consumes. Well-designed modern plants achieve this by using their own syngas as fuel.

Emissions and Contaminant Control

While it avoids the direct combustion emissions of incineration, the process is not emission-free. Improperly managed pyrolysis can release volatile organic compounds (VOCs) and other pollutants. Sophisticated gas cleanup and control systems are essential for any environmentally sound operation.

Feedstock Quality is Critical

The composition of the waste feedstock directly impacts the quality and safety of the final products. Contaminants in the waste stream, such as PVC plastic or heavy metals, can end up in the oil or char, limiting their use and requiring further costly purification.

Making the Right Choice for Your Goal

Evaluating pyrolysis requires aligning its capabilities with your specific objective.

- If your primary focus is large-scale waste management: Pyrolysis is an excellent technology for reducing landfill volume and handling difficult, non-recyclable materials like mixed plastics and tires.

- If your primary focus is creating circular materials: Chemical recycling via pyrolysis is one of the most promising methods for breaking down polymers into feedstocks to produce new, virgin-quality plastics.

- If your primary focus is carbon sequestration: Pyrolysis of clean biomass to create biochar for agricultural use is a proven and effective carbon dioxide removal strategy.

- If your primary focus is renewable energy generation: The process can produce valuable liquid and gaseous fuels, but you must carefully analyze the net energy balance and feedstock logistics.

Ultimately, pyrolysis offers a compelling pathway toward sustainability, but its success hinges on careful planning, responsible operation, and a clear understanding of its role within a broader circular system.

Summary Table:

| Sustainability Pillar | Key Benefit |

|---|---|

| Waste Diversion | Reduces landfill volume and methane emissions from non-recyclable materials. |

| Circular Economy | Breaks down waste into chemical feedstocks for new products, reducing virgin resource use. |

| Alternative Energy | Produces bio-oil and syngas that can displace fossil fuels. |

| Carbon Sequestration | Biochar from biomass locks away carbon in soil for centuries. |

Ready to integrate sustainable pyrolysis technology into your lab or waste management process? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Our solutions help you accurately analyze feedstocks, optimize processes, and validate outputs like bio-oil and biochar. Enhance your sustainability projects with precision equipment—contact our experts today to find the right tools for your circular economy goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output