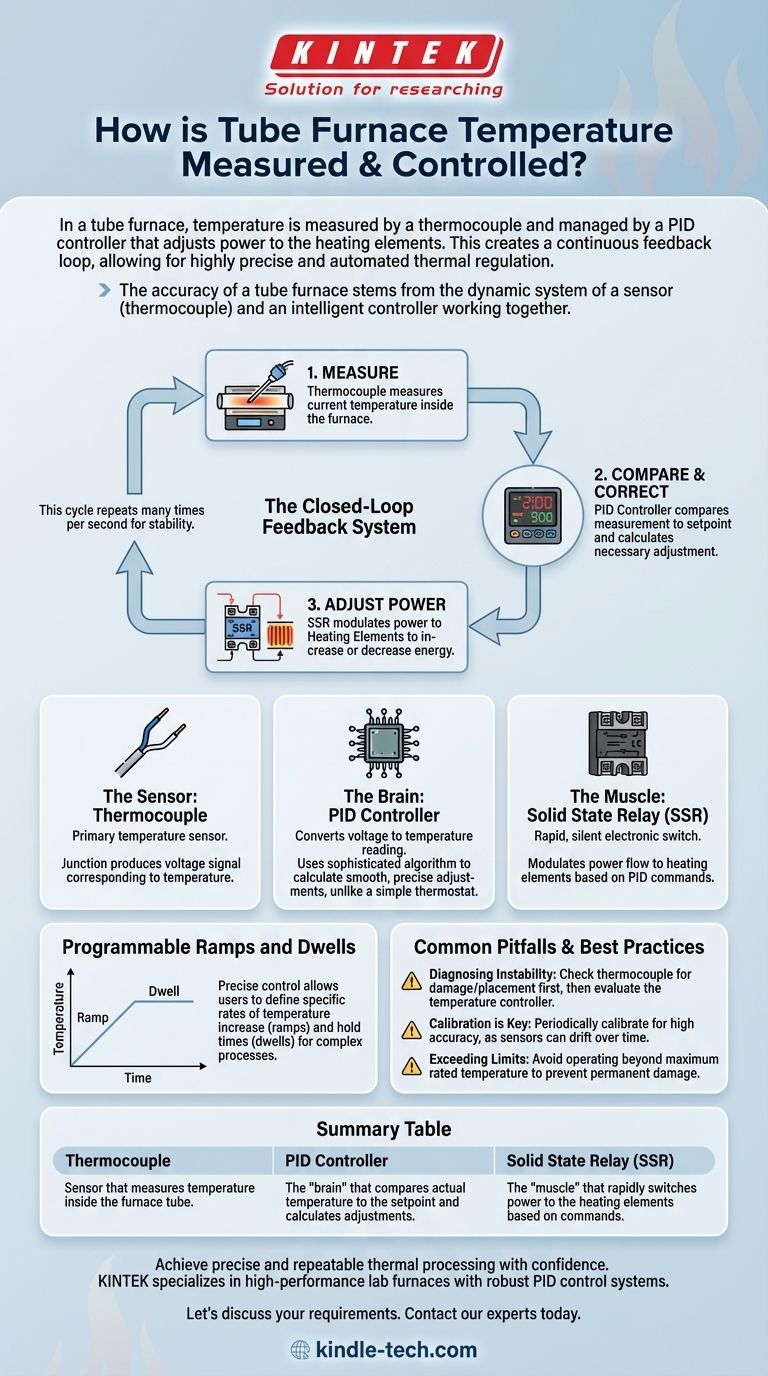

In a tube furnace, temperature is measured by a thermocouple and managed by a PID controller that adjusts power to the heating elements. This creates a continuous feedback loop, allowing for highly precise and automated thermal regulation.

The accuracy of a tube furnace stems not from a single component, but from the dynamic system of a sensor (the thermocouple) and an intelligent controller working together. This system constantly measures, compares, and corrects the temperature to match a desired setpoint with remarkable stability.

The Core Components of Temperature Control

To understand how a tube furnace achieves its precision, we must first look at the key components responsible for the task. Each part plays a distinct and critical role in the control loop.

The Sensor: The Thermocouple's Role

A thermocouple is the primary temperature sensor inside the furnace. It is a simple yet effective device made of two different metals joined at one end.

When this junction is heated, it produces a small voltage that corresponds directly to the temperature. This signal is the raw data that feeds the entire control system.

The Brain: The PID Controller

The PID (Proportional-Integral-Derivative) controller is the intelligent heart of the system. It receives the voltage signal from the thermocouple and converts it into a temperature reading.

Unlike a simple thermostat that just turns heating on or off, a PID controller uses a sophisticated algorithm. It continuously calculates the difference between the actual temperature and your setpoint, predicting how the system will behave to make smooth, precise adjustments.

The Muscle: The Solid State Relay (SSR)

The PID controller sends its commands to a Solid State Relay (SSR) or a similar device like a silicon-controlled rectifier.

The SSR acts as a rapid, silent, and highly durable electronic switch. It modulates the flow of power to the furnace's heating elements with incredible speed, allowing for the fine-tuned adjustments dictated by the PID controller.

How the System Works in Harmony

These individual components form a cohesive, closed-loop system that enables the furnace's advanced capabilities. The process is a constant, self-correcting cycle.

The Closed-Loop Feedback System

The control process is a continuous loop:

- Measure: The thermocouple measures the current temperature.

- Compare: The PID controller compares this measurement to the programmed setpoint.

- Correct: The controller calculates the necessary power adjustment and instructs the SSR to increase or decrease energy to the heating elements.

This cycle repeats many times per second, preventing temperature overshoots and undershoots and maintaining exceptional stability.

Programmable Ramps and Dwells

This precise control system is what allows a tube furnace to be programmed. Users can define specific rates of temperature increase (ramps) and hold times at specific temperatures (dwells).

This level of programmable control is essential for complex material processing, annealing, and scientific experiments where the thermal history of the sample is critical.

Common Pitfalls and Troubleshooting

Even with a sophisticated system, issues can arise. Understanding the potential points of failure is key to maintaining accuracy and reliability.

Diagnosing Temperature Instability

If you experience significant temperature fluctuations, the problem almost always lies with the two primary control components.

The first step in troubleshooting is to check the thermocouple for damage or improper placement. The second step is to evaluate the temperature controller itself, as its internal electronics can fail or drift over time.

The Importance of Calibration

For applications requiring high accuracy, the thermocouple and controller system must be periodically calibrated. Over time and with thermal cycling, a sensor's readings can drift slightly.

Recalibration ensures that the temperature displayed on the controller is a true reflection of the temperature inside the furnace tube.

Exceeding Operational Limits

Every furnace is designed with a maximum rated temperature. Operating the furnace beyond this limit can cause permanent damage to the heating elements and the thermocouple.

This not only shortens the equipment's lifespan but also compromises the accuracy of all future temperature measurements.

Ensuring Accurate and Repeatable Results

Your approach to operating a tube furnace should be guided by your primary experimental or production goal.

- If your primary focus is process precision: Leverage the PID controller's programmable features for ramps and dwells, and ensure your system is regularly calibrated.

- If your primary focus is troubleshooting fluctuations: Always begin by inspecting the thermocouple and its connection to the controller before suspecting a more complex failure.

- If your primary focus is equipment longevity: Strictly adhere to the furnace's rated temperature limits to protect the heating elements and ensure long-term sensor accuracy.

Understanding this elegant control system empowers you to achieve highly reliable and repeatable thermal processing for your critical applications.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Thermocouple | Sensor that measures temperature inside the furnace tube. |

| PID Controller | The "brain" that compares actual temperature to the setpoint and calculates adjustments. |

| Solid State Relay (SSR) | The "muscle" that rapidly switches power to the heating elements based on the controller's commands. |

Achieve precise and repeatable thermal processing with confidence.

Understanding the sophisticated control system of a tube furnace is key to your success. For applications requiring the highest level of temperature accuracy and stability—from materials research to sample preparation—you need equipment you can trust.

KINTEK specializes in high-performance lab furnaces and consumables, serving the exacting needs of laboratories worldwide. Our tube furnaces are engineered with robust PID control systems to deliver the reliable results your work depends on.

Let's discuss your specific thermal processing requirements. Contact our experts today to find the perfect solution for your laboratory.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How do tube furnaces or atmosphere furnaces facilitate the final crystallization sintering of Li10GeP2S12 (LGPS)?

- What are the advantages of using a Monel alloy tubular reactor? Ensure High Purity in Graphene Fluorination

- What is the role of a tube furnace or atmosphere furnace in lignin-based carbon fibers? Expert Insights

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- How do high-temperature tube furnaces maintain accuracy in sulfur oxide atmospheres? Ensure Precise Gas Control

- How does a tube furnace facilitate the carbon coating process for lithium-based anode materials? Boost Battery Performance

- What is the function of a laboratory vertical tube furnace in microalgae catalytic pyrolysis? Optimize Your Bio-Fuel.

- How does a Tube Atmosphere Furnace ensure stability for steam oxidation? Master Precise Alloy Testing