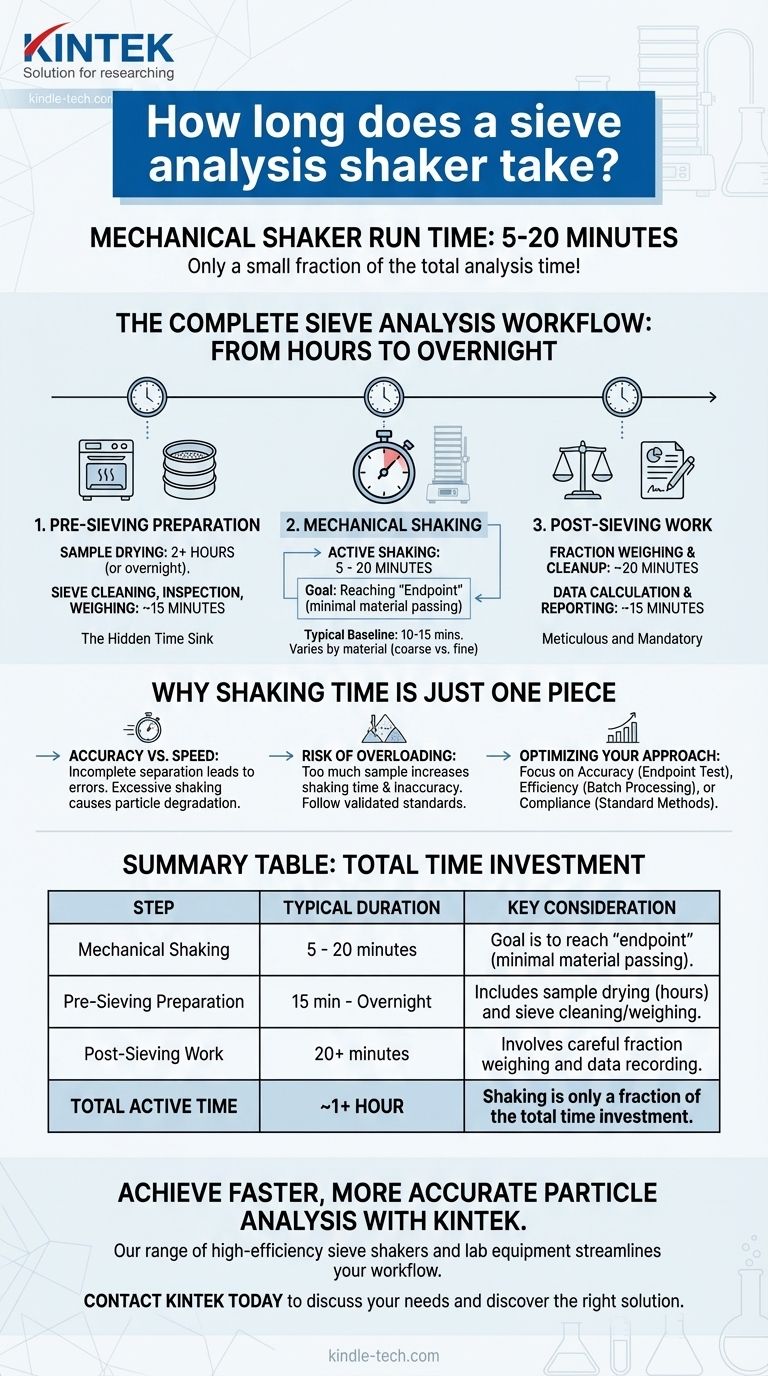

For a typical sieve analysis, the mechanical shaker itself usually runs for a period of 5 to 20 minutes. This duration, however, is only a small fraction of the total time required for a complete sieve analysis. The actual shaking is a relatively quick step bracketed by much more time-consuming preparation and evaluation procedures.

The most common mistake is focusing on the shaker's run time. The true duration of a sieve analysis is dictated by the mandatory preparation and post-analysis steps, which can easily extend the entire process from under an hour to several hours.

The Shaking Process Itself: A Matter of Minutes

While the shaker is the active part of the analysis, its duration is determined by the material and the goal of the test, not a fixed universal standard.

Establishing a Typical Baseline

For most common materials like sand, aggregates, or free-flowing powders, a run time of 10 to 15 minutes is a standard starting point. This is often sufficient to achieve adequate particle separation.

Factors Influencing Shaker Time

The optimal time varies based on several factors. Coarse materials may separate quickly in as little as 5 minutes, while very fine or slightly cohesive powders may require 20 minutes or more to properly pass through the mesh.

The Technical Goal: Reaching "Endpoint"

The goal of shaking is to reach the "endpoint," the point at which continued sieving no longer results in a significant amount of material passing through any given sieve. A common industry rule is that the endpoint is reached when less than 1% of the material on a sieve passes through it during one minute of additional shaking.

Why Shaker Time is Just One Piece of the Puzzle

The overall workflow, as outlined in standard testing methods, shows that the mechanical shaking step is just one component among many. The other steps are what truly consume the bulk of the time and labor.

Pre-Sieving Preparation: The Hidden Time Sink

Before the shaker is even turned on, significant time is invested. This includes sample preparation, which may involve drying a sample in an oven for several hours or overnight to remove moisture. It also includes the meticulous task of cleaning, inspecting, and weighing each individual empty sieve.

Post-Sieving Work: Meticulous and Mandatory

After the shaking stops, the work is far from over. Each sieve must be carefully removed from the stack, and the material fraction retained on it must be weighed precisely. This process, known as back-weighing, requires care to avoid losing any sample material.

A Realistic Timeline Example

Consider a single sample:

- Sample Drying: 2+ hours (if required)

- Sieve Prep & Weighing: 15 minutes

- Sample Weighing & Loading: 5 minutes

- Mechanical Shaking: 10 minutes

- Fraction Weighing & Cleanup: 20 minutes

- Data Calculation & Reporting: 15 minutes

In this realistic scenario, the 10-minute shaking accounts for only a small portion of the 1 hour and 5 minutes of active work, not including the lengthy drying time.

Understanding the Trade-offs

Optimizing sieve analysis requires balancing speed with the fundamental need for accurate and repeatable results.

Accuracy vs. Speed

Shaking for too little time is the most critical error. It results in incomplete separation, where finer particles are incorrectly counted as part of a coarser fraction, invalidating the entire test. Conversely, excessive shaking offers no benefit and can, in some cases, cause particle degradation (attrition), which also skews results.

The Risk of Overloading

Placing too much sample material onto the top sieve is a common mistake made to save time. This overloads the mesh, preventing particles from having a fair chance to pass through. It dramatically increases the required shaking time and produces an inaccurate result. Following a validated standard method is the only way to know the correct sample size.

How to Apply This to Your Project

Your approach to sieve analysis timing should be guided by your ultimate goal.

- If your primary focus is accuracy and reproducibility: Perform an endpoint determination test for each new material type to establish a standardized, validated shaking time.

- If your primary focus is high-throughput and efficiency: Streamline your workflow by preparing and weighing sieves in batches and creating an efficient station for post-shaking weighing and data entry.

- If you are performing a test for compliance or certification: Disregard any "typical" times and follow the specified standard method (e.g., from ASTM or ISO) precisely, as it will dictate sample size, shaker settings, and duration.

Ultimately, a reliable particle size analysis is built on a consistent process, where the shaker's run time is a validated constant, not a variable to be adjusted.

Summary Table:

| Step | Typical Duration | Key Consideration |

|---|---|---|

| Mechanical Shaking | 5 - 20 minutes | Goal is to reach 'endpoint' (minimal material passing). |

| Pre-Sieving Preparation | 15 min - Overnight | Includes sample drying (hours) and sieve cleaning/weighing. |

| Post-Sieving Work | 20+ minutes | Involves careful fraction weighing and data recording. |

| Total Active Time | ~1+ hour | Shaking is only a fraction of the total time investment. |

Achieve faster, more accurate particle analysis with KINTEK.

Our range of high-efficiency sieve shakers and lab equipment is designed to streamline your workflow, from sample preparation to data reporting. Let our experts help you optimize your process for maximum throughput and reliability.

Contact KINTEK today to discuss your specific laboratory needs and discover the right solution for you.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Shaking Incubators for Diverse Laboratory Applications

People Also Ask

- What size are test sieves? A Guide to Frame Diameters and Mesh Sizes

- Can sieving be used to separate a solid substance from a liquid substance? Learn the Right Technique for Your Mixture

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Which Cannot be separated by sieving? Understanding the Limits of Particle Size Separation

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits