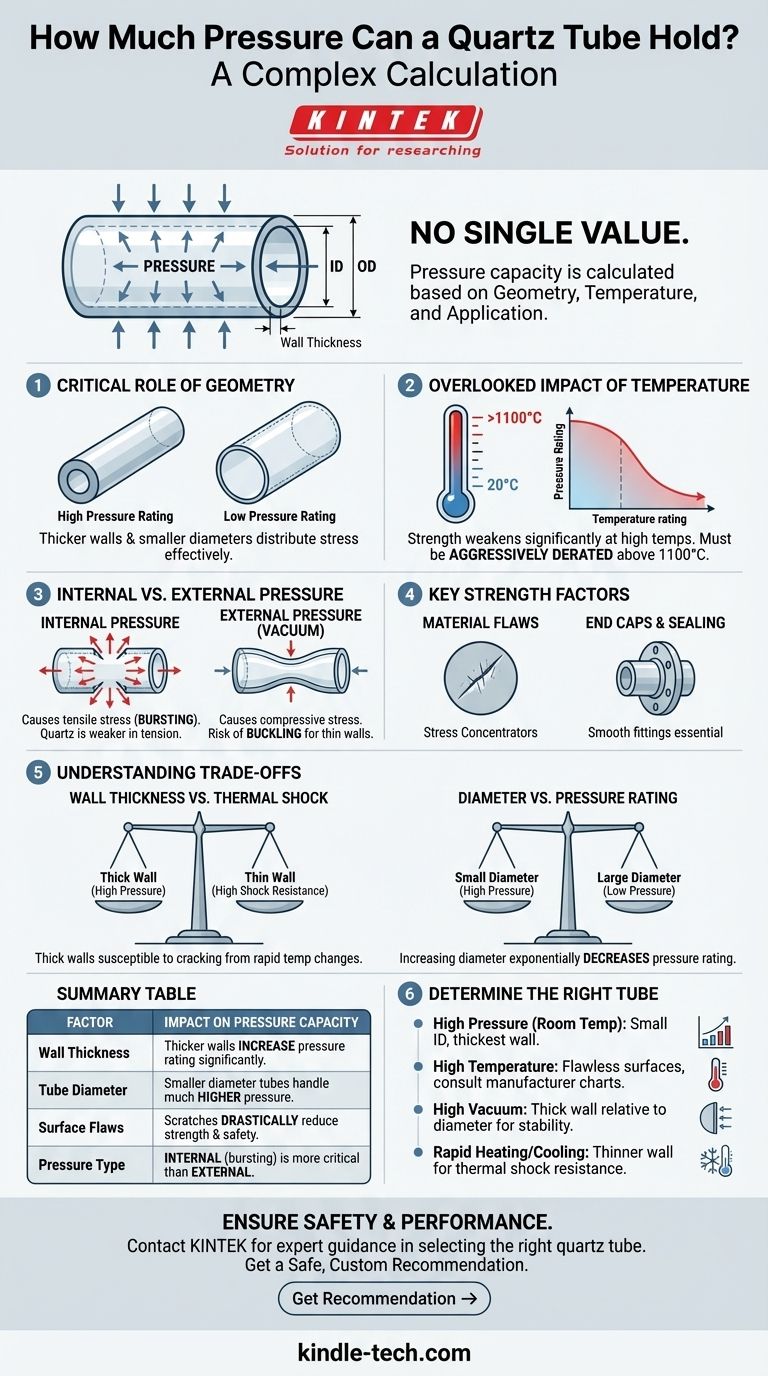

The pressure capacity of a quartz tube is not a single value but a complex calculation based on its specific dimensions, operating temperature, and application. Unlike metals, which have standardized pressure ratings, the brittle nature of quartz means its strength is dictated by factors like wall thickness, diameter, and surface quality. A thick-walled, small-diameter tube at room temperature might handle tens of atmospheres, while a large, thin-walled tube at 1000°C may only be safe for a slight vacuum.

The safe operating pressure of a quartz tube is a calculated value specific to your exact tube and operating conditions, not a fixed property of the material. It is critically dependent on the wall thickness-to-diameter ratio and decreases sharply with increasing temperature.

Why There Is No Single Answer

Asking how much pressure a quartz tube can hold is like asking how much weight a rope can support. The answer immediately depends on the rope's thickness, material, and condition. For quartz tubes, the same principles apply, but the material's properties introduce unique considerations.

The Critical Role of Geometry

The most important factors are the tube's Outer Diameter (OD), Inner Diameter (ID), and the resulting wall thickness.

Internal pressure creates a "hoop stress" that tries to pull the tube walls apart. A thicker wall and a smaller diameter distribute this stress more effectively, dramatically increasing the pressure rating.

The Overlooked Impact of Temperature

Fused quartz maintains its strength very well up to a point, but it weakens significantly at elevated temperatures.

The material begins to soften above 1100°C. Therefore, any pressure calculations must be aggressively derated for high-temperature work. A tube safe for 5 bar at 20°C may not be safe for even 1.1 bar at 1000°C.

Internal vs. External Pressure

The failure mode is different for internal and external pressure.

- Internal Pressure: Causes tensile stress, leading to bursting. Quartz is much weaker under tension.

- External Pressure (Vacuum): Causes compressive stress. While quartz is incredibly strong in pure compression, a thin-walled tube under external pressure can fail by buckling or collapsing long before the material's compressive strength is reached.

Key Factors That Determine Strength

Beyond the core variables of geometry and temperature, several other factors can drastically affect the safe operating pressure of your system.

Material Purity and Flaws

Quartz is a brittle material. This means that microscopic scratches, inclusions, or imperfections on the surface act as stress concentrators.

A tiny, invisible scratch can be the initiation point for a catastrophic fracture under pressure. This is why it is critical to handle quartz tubes carefully and inspect them for any surface damage.

End Caps and Sealing Methods

How you seal the ends of the tube is a common point of failure. Sharp corners on flanges or overtightened clamps can introduce localized stress that will crack the tube well below its theoretical pressure limit.

Smooth, well-designed fittings that distribute the load evenly are essential for any pressurized quartz system.

Understanding the Critical Trade-offs

Choosing a quartz tube often involves balancing competing requirements. Understanding these trade-offs is key to a safe and successful design.

Wall Thickness vs. Thermal Shock Resistance

A thicker wall provides a higher pressure rating. However, it also creates a larger temperature gradient across the glass when heated or cooled.

This gradient induces stress, making thick-walled tubes much more susceptible to cracking from thermal shock. If your process involves rapid temperature changes, a thinner wall may be necessary, which in turn limits your operating pressure.

Diameter vs. Pressure Rating

For a given wall thickness, increasing the tube's diameter exponentially decreases its pressure rating.

This means that scaling up a process from a 1-inch tube to a 4-inch tube requires a complete recalculation of safety limits. You cannot assume the pressure performance will be similar.

How to Determine the Right Tube for Your Application

There is no universal calculator for quartz tube pressure ratings because of the variables involved, especially material flaws. You must always consult the original manufacturer for guidance and apply a conservative safety factor.

- If your primary focus is high pressure at room temperature: Prioritize a tube with the smallest possible inner diameter and the thickest possible wall.

- If your primary focus is high-temperature operation: Your maximum pressure will be severely limited. Select a tube with flawless surfaces and consult manufacturer charts for temperature derating.

- If you are working with a high vacuum (external pressure): Buckling is the primary risk. A thick wall relative to the diameter is the most important factor for stability.

- If you require rapid heating and cooling: You must prioritize thermal shock resistance by using a thinner wall, which will significantly lower your safe pressure limit.

Ultimately, you must treat any pressurized glass system with extreme care, using appropriate safety shields and operating well within the calculated limits for your specific components and conditions.

Summary Table:

| Factor | Impact on Pressure Capacity |

|---|---|

| Wall Thickness | Thicker walls increase pressure rating significantly. |

| Tube Diameter | Smaller diameter tubes can handle much higher pressure. |

| Temperature | Capacity decreases sharply above 1100°C; requires aggressive derating. |

| Surface Flaws | Scratches or imperfections drastically reduce strength and safety. |

| Pressure Type | Internal pressure (bursting) is more critical than external (vacuum/buckling). |

Ensure the safety and performance of your high-temperature or pressurized processes. The pressure rating of a quartz tube is highly specific to your application's geometry, temperature, and conditions. Don't risk equipment failure or safety hazards.

Contact KINTEK today for expert guidance in selecting the right quartz tube for your laboratory's unique needs. Our specialists will help you calculate safe operating limits and provide high-purity, flaw-inspected lab equipment designed for reliability.

Get a Safe, Custom Recommendation →

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between a pressure switch and a vacuum switch? Understand Their Critical Roles in System Safety

- Why are high-density grinding media used for magnesium-based amorphous powders? Master Kinetic Energy Transfer

- How does a high-precision platinum-rhodium thermocouple contribute to calculating activation energy? | KINTEK

- Why is the selection of materials for grinding vials and grinding balls critical? Master HEA Powder Purity

- What are the parts of a kiln sitter? A Guide to the Essential Safety Mechanism

- Why are zirconia ball mill jars required for zirconium halide electrolytes? Ensure Pure, High-Conductivity Synthesis

- What role does an ultrasonic cleaner play in the pre-treatment of 4140 steel? Ensure Uniform Nitriding Activation

- How does a laboratory magnetic stirrer function? Master Composite Coating Preparation with KINTEK