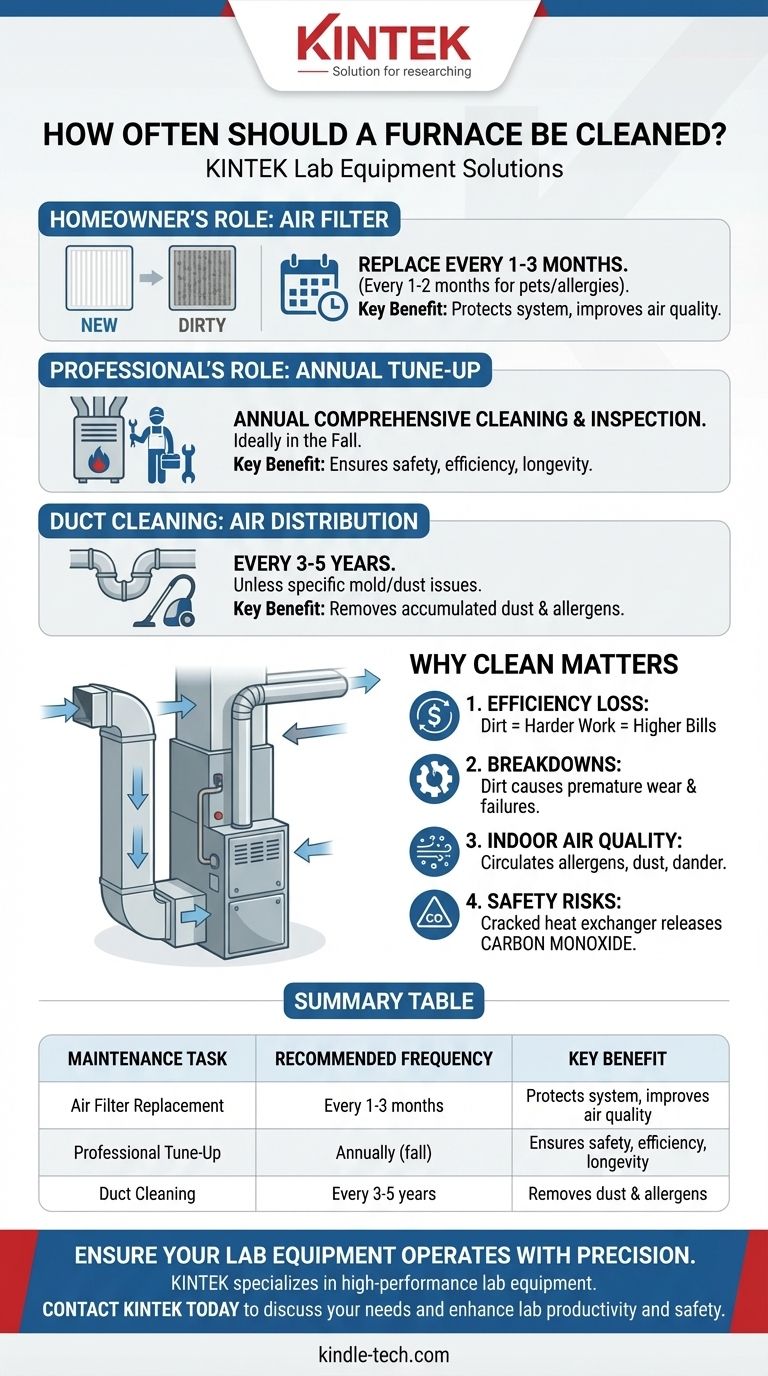

For a residential furnace, the most critical cleaning task is replacing the air filter every 1-3 months. For a comprehensive professional cleaning and safety inspection—often called a "tune-up"—the standard recommendation is to have it done once per year, ideally in the fall before the heating season begins.

The core principle of furnace maintenance is separating homeowner tasks from professional service. While you are responsible for frequent filter changes, an annual professional tune-up is essential for ensuring the system's safety, efficiency, and longevity.

Why a Clean Furnace Matters More Than You Think

Neglecting furnace maintenance is not a passive act; it actively degrades your system and home environment. The accumulation of dust and soot has direct, measurable consequences.

The Cost of Neglect: Efficiency Loss

A dirty furnace works harder to produce the same amount of heat. Clogged filters restrict airflow, and dirty components struggle to transfer heat effectively. This forces the system to run longer, directly increasing your fuel consumption and utility bills.

Protecting Your System from Breakdowns

Dirt and dust are the primary enemies of mechanical systems. They cause components like the blower motor and ignition system to wear out prematurely. An annual cleaning and inspection can catch these issues before they lead to a complete system failure, often in the middle of winter.

The Impact on Indoor Air Quality

Your furnace circulates all the air in your home multiple times a day. If the system is dirty, it is actively distributing dust, dander, and other allergens. Regular filter changes and periodic duct cleaning are fundamental to maintaining healthy indoor air.

The Two Levels of Furnace Maintenance

It's crucial to understand the difference between the simple tasks you should perform and the comprehensive service best left to a qualified technician.

The Homeowner's Role: The Air Filter

This is the single most important task you can do. The furnace air filter traps airborne particles before they can enter and damage the system's sensitive components.

A dirty filter is a roadblock for air. Check your filter monthly and replace it at least every 3 months. Homes with pets, smokers, or allergy sufferers should change it every 1-2 months.

The Professional's Role: Annual Tune-Up

A technician performs a deep cleaning and safety inspection that goes far beyond the filter. This includes cleaning burners, inspecting the heat exchanger for dangerous cracks, checking electrical connections, and ensuring the system is combusting fuel safely and efficiently. This is the annual service experts recommend.

A Note on Duct Cleaning

While the furnace itself should be serviced annually, the ductwork that distributes the air has a different schedule. Unless you have specific issues with mold or excessive dust, a professional duct cleaning is typically recommended only every 3 to 5 years.

Common Pitfalls to Avoid

Skipping maintenance can seem like a way to save money in the short term, but it often leads to much greater expenses and risks down the line.

Short-Term Savings vs. Long-Term Costs

The fee for an annual tune-up is a minor, predictable expense. It is an investment to prevent an unexpected and expensive breakdown, which can easily cost ten times as much. Proactive maintenance is always more cost-effective than reactive repair.

Voided Warranties

Many furnace manufacturers stipulate in their warranty terms that the system must receive regular professional maintenance. If your system fails while under warranty and you cannot provide service records, your claim may be denied, leaving you to cover the full cost of a major repair.

Critical Safety Risks

The most important reason for an annual inspection is safety. A technician will inspect the heat exchanger, a metal chamber that separates the air you breathe from the toxic combustion gases. A crack in this component can leak deadly, odorless carbon monoxide into your home. This is a risk that should never be taken.

How to Apply This to Your System

Translate this knowledge into a simple, actionable plan based on your primary goal for your HVAC system.

- If your primary focus is maximum efficiency and longevity: Schedule a professional tune-up every fall and change your air filter monthly.

- If your primary focus is safety on a practical budget: Do not go more than two years without a professional inspection, and replace your air filter religiously every three months.

- If your primary focus is improving indoor air quality: Change your filter every 1-2 months using a high-quality pleated filter and schedule a duct cleaning every 3 years.

Consistent, simple maintenance is the definitive way to ensure your furnace operates safely and reliably for its entire intended lifespan.

Summary Table:

| Maintenance Task | Recommended Frequency | Key Benefit |

|---|---|---|

| Air Filter Replacement | Every 1-3 months | Protects system, improves air quality |

| Professional Tune-Up | Annually (ideally in fall) | Ensures safety, efficiency, longevity |

| Duct Cleaning | Every 3-5 years | Removes accumulated dust and allergens |

Ensure your lab equipment operates with the same precision and reliability as a well-maintained furnace. KINTEK specializes in high-performance lab equipment and consumables, providing the tools you need for accurate and efficient results. From ovens and furnaces to essential lab supplies, we support your laboratory's success. Contact KINTEK today to discuss your specific needs and discover how our solutions can enhance your lab's productivity and safety.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is brazing vs soldering? Choose the Right Joining Method for Strength vs. Precision

- Does melting point ever change? Unlock the Secrets of Pressure and Purity

- Why do we need to use properly some of the laboratory apparatus in the laboratory? The Foundation of Safe and Accurate Science

- What is the difference between a crucible and a furnace? Understanding the Heat Source and Container Partnership

- What affects the melting point of a substance? Uncover the Key Factors & Forces