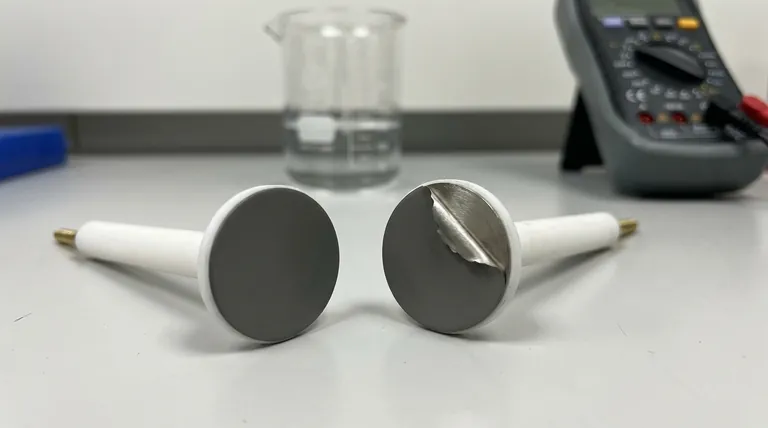

When a titanium electrode's coating is partially peeled, you must immediately stop operations and inspect the damage. For minor peeling that covers less than 5% of the total surface area, you may be able to continue operation at a reduced current density. However, if the damage is more significant, the electrode must be replaced to prevent catastrophic process failure and ensure operational integrity.

The peeling of a titanium electrode's coating is a critical failure indicator. While minor damage might seem manageable, it signals an underlying issue and creates a point of weakness that will inevitably lead to accelerated degradation, reduced efficiency, and potential contamination of your process.

Diagnosing the Extent of the Damage

The first step is to assess the situation methodically. A rushed judgment can lead to either unnecessary expense or a much larger system failure down the line.

Immediate Action: Stop the Process

The moment peeling is suspected or observed, halt all electrical current and remove the electrode from the system.

Continuing to operate with an exposed substrate can cause arcing, a dramatic increase in voltage, and rapid destruction of the remaining coating as current density spikes on the intact surfaces.

The 5% Rule for Damage Assessment

Carefully inspect the entire surface of the electrode. The established rule of thumb is to quantify the damaged area.

If the peeled or damaged area is less than 5% of the total active surface, the electrode may be cautiously returned to service.

If the damage is greater than 5%, the electrode is no longer considered reliable and must be taken out of commission permanently.

Why a Damaged Coating Is a Critical Failure

The specialized coating (often a mixed metal oxide, or MMO) is the catalytically active component. The titanium underneath is merely a substrate.

When the coating peels, the exposed titanium passivates almost instantly in the electrolyte, forming an inert, non-conductive layer of titanium dioxide (TiO₂). This passivated area no longer contributes to the reaction, forcing the remaining coating to work harder and fail faster.

Understanding the Root Causes of Peeling

To prevent recurrence, you must understand why the failure occurred. Peeling is not random; it is a symptom of operational stress.

Excessive Current Density

This is the most common operational cause. Every electrode has a maximum designed current density. Exceeding it generates excessive heat and gas at the coating-substrate interface, physically pushing the coating off.

Physical Impact or Abrasion

The catalytic coatings are hard but can be brittle. Dropping the electrode, scraping it against the cell tank, or overly aggressive cleaning can easily chip or crack the coating, creating a starting point for peeling.

Improper Shutdown Procedures

Abruptly cutting power to the cell can create a reverse potential. This momentary reversal of polarity can chemically attack the delicate bond between the coating and the titanium, weakening it over time and leading to delamination.

Understanding the Trade-offs: Repair vs. Replace

The decision to continue using a damaged electrode is a calculated risk. There is no scenario where a field repair is a viable option.

The Case for Continued Use (with Caution)

Using an electrode with less than 5% damage is a short-term solution to maintain production.

The trade-off is accepting reduced performance. You must operate at a lower current density to avoid overloading the remaining coating. This means lower production rates and a shorter overall lifespan for the electrode.

The Inevitability of Replacement

Once peeling begins, it is a cascading failure. The exposed edge of the intact coating becomes a new stress riser, making it the most likely point for further peeling.

For any damage over 5%, or for any process where consistency and purity are paramount, replacement is the only technically sound decision.

Why Field Repairs Are Not Viable

The application of MMO coatings is a highly specialized industrial process involving chemical preparation, precise application, and high-temperature curing in controlled atmospheres.

Attempting to "patch" a coating in the field is impossible and will only serve to contaminate your process and accelerate the failure of the surrounding area.

A Proactive Strategy for Electrode Longevity

To maximize the life of your titanium electrodes and ensure process stability, your focus should shift from reactive repair to proactive maintenance and proper handling.

- If your primary focus is immediate production continuity: For damage under 5%, reduce the current density to protect the remaining coating and schedule a replacement during the next maintenance window.

- If your primary focus is process efficiency and quality: Replace any electrode with visible peeling, as the compromised surface will increase power consumption and introduce a risk of failure.

- If your primary focus is long-term cost reduction: Implement and enforce strict operational protocols for handling, current limits, and gradual power-down to prevent the root causes of peeling.

A well-maintained electrode is the foundation of a reliable and efficient electrochemical process.

Summary Table:

| Action | Condition | Recommendation |

|---|---|---|

| Continue Operation | Damage < 5% of surface area | Use with caution at a reduced current density. |

| Replace Electrode | Damage > 5% of surface area | Immediate replacement is required to prevent system failure. |

| Root Cause | Common Causes | Excessive current density, physical impact, improper shutdown. |

Ensure your electrochemical processes run with maximum efficiency and reliability. A damaged electrode can lead to costly downtime and contamination. KINTEK specializes in high-performance lab equipment and consumables, including robust electrochemical cells and replacement electrodes. Our experts can help you select the right components and implement best practices for electrode longevity. Contact our team today to discuss your specific needs and protect your process integrity.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Metal Disc Electrode Electrochemical Electrode

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- What is the difference between RDE and RRDE? Unlock Advanced Electrochemical Reaction Analysis

- How should a platinum wire/rod electrode be cleaned before use? A Guide to Reliable Electrochemical Data

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What is a common application for the platinum wire/rod electrode? The Essential Guide to Counter Electrodes

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights