To properly maintain a platinum sheet electrode, you must implement a strict protocol of gentle handling, rigorous cleaning, and careful storage. This involves inspecting the surface before each use, rinsing it with deionized water immediately after, and storing it in a dry, protected container to prevent both physical damage and chemical contamination.

The core objective of maintaining a platinum electrode is not just cleanliness, but the preservation of its pristine, catalytically active surface. The quality and reproducibility of your electrochemical data depend directly on the consistent and uncontaminated state of this surface.

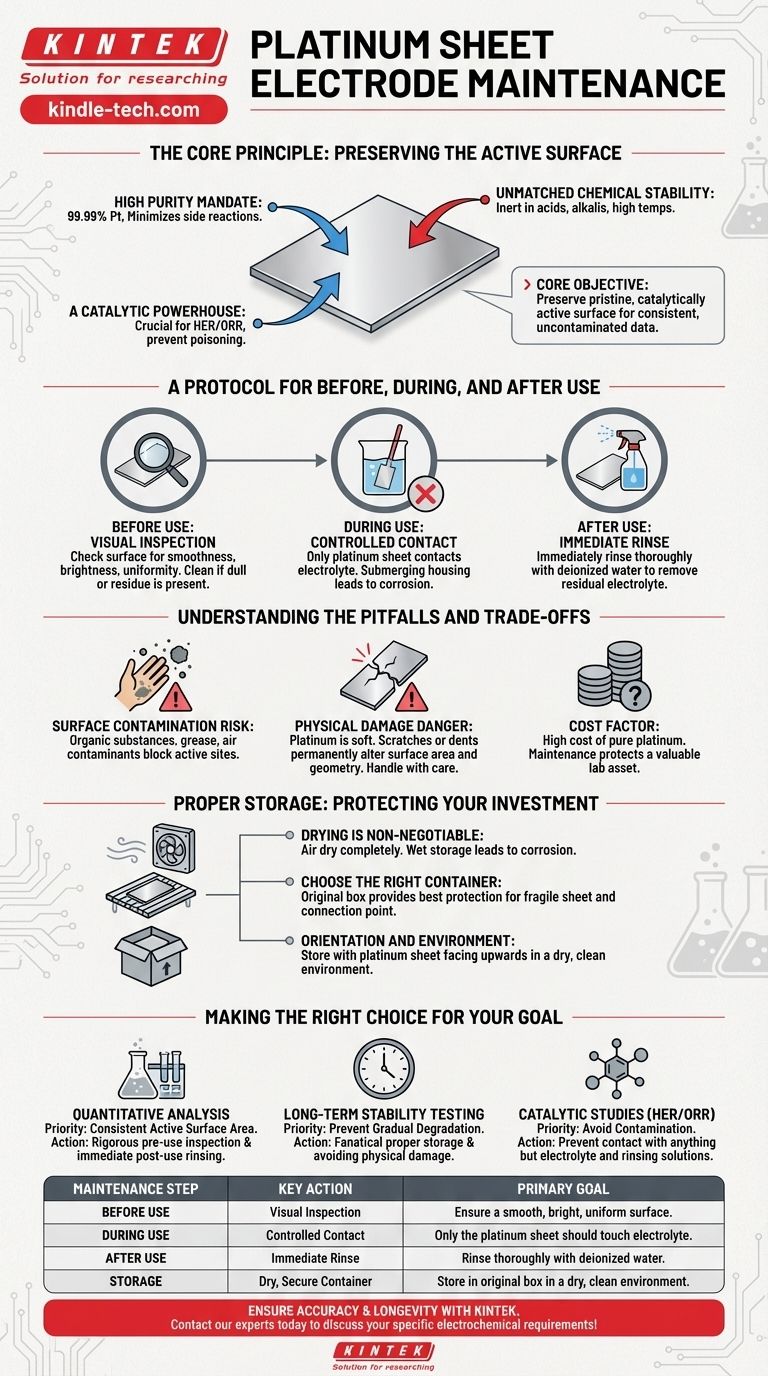

The Core Principle: Preserving the Active Surface

A platinum electrode is a high-precision instrument, not a simple piece of metal. Its value lies in the unique properties of its surface, which your maintenance routine is designed to protect.

The High Purity Mandate

The platinum used in these electrodes typically has a purity of 99.99%. This exceptional purity minimizes side reactions and ensures that the electrochemical behavior you observe is characteristic of platinum, leading to accurate and reliable data.

Unmatched Chemical Stability

Platinum is renowned for its chemical inertness. It remains stable in strong acids, strong alkalis, and high-temperature environments, making it suitable for a wide range of electrochemical experiments without degrading.

A Catalytic Powerhouse

The platinum surface exhibits excellent catalytic performance for critical electrochemical processes like the hydrogen evolution reaction (HER) and the oxygen reduction reaction (ORR). Any contamination or damage to this surface can "poison" these catalytic sites, altering your results.

A Protocol for Before, During, and After Use

Adhering to a consistent workflow is the most effective way to extend the life of your electrode and ensure the integrity of your experiments.

Before Each Experiment: Visual Inspection

Before immersing the electrode, always inspect the platinum surface. It should appear smooth, bright, and uniform. If you notice any dullness, discoloration, or residue, it must be cleaned and re-treated before proceeding.

During the Experiment: Controlled Contact

It is imperative that only the platinum sheet makes contact with your electrolyte solution. Submerging any other part of the electrode, such as the housing or connection point, can lead to corrosion and contamination of your sample.

Immediately After Use: The Rinse Protocol

As soon as the experiment is complete, remove the electrode and immediately rinse the platinum surface thoroughly with deionized water. This removes residual electrolyte before it can dry and crystallize, which can damage or passivate the surface.

Understanding the Pitfalls and Trade-offs

Proper maintenance is about mitigating risks. Being aware of the most common failure modes is critical for protecting your investment and your data.

The Risk of Surface Contamination

The most common problem is surface contamination. Contact with organic substances, greases, or even contaminants from the air can block the active sites on the platinum surface, drastically affecting its performance.

The Danger of Physical Damage

Platinum is a soft metal. The thin sheet is fragile and susceptible to scratches, dents, or deformation. Any physical damage permanently alters the electrode's geometry and active surface area, introducing an uncontrolled variable into your measurements. Always handle with care.

The Cost Factor

These electrodes are expensive due to the high cost of pure platinum. A disciplined maintenance routine is not just good science; it is sound financial management that protects a valuable laboratory asset.

Proper Storage: Protecting Your Investment

How you store the electrode between uses is just as important as how you clean it. Improper storage is a primary cause of gradual performance degradation.

Drying is Non-Negotiable

After the final deionized water rinse, allow the electrode to air dry completely. Storing it while wet can trap moisture and lead to slow corrosion or contamination.

Choose the Right Container

The original box is often the best storage container. It is designed to hold the electrode securely and protect the fragile platinum sheet and the critical connection point from physical impact.

Orientation and Environment

Store the electrode in a dry, clean environment with the platinum sheet facing upwards, if possible. This minimizes contact with any container surfaces and reduces the chance of dust or other airborne particles settling on the active surface.

Making the Right Choice for Your Goal

Your specific experimental goal should guide the focus of your maintenance efforts.

- If your primary focus is quantitative analysis: Your top priority is a consistent active surface area. Rigorous pre-use inspection and immediate post-use rinsing are non-negotiable.

- If your primary focus is long-term stability testing: You must be fanatical about proper storage and avoiding physical damage to prevent gradual, uncontrolled changes in electrode performance over time.

- If your primary focus is catalytic studies (e.g., HER/ORR): Your greatest enemy is contamination. You must prevent the surface from touching anything other than the electrolyte and rinsing solutions to avoid poisoning the catalytic sites.

By treating your platinum electrode as the precision instrument it is, you ensure the long-term integrity of your research.

Summary Table:

| Maintenance Step | Key Action | Primary Goal |

|---|---|---|

| Before Use | Visual Inspection | Ensure a smooth, bright, and uniform surface. |

| During Use | Controlled Contact | Only the platinum sheet should touch the electrolyte. |

| After Use | Immediate Rinse | Rinse thoroughly with deionized water to remove residue. |

| Storage | Dry, Secure Container | Store in original box in a dry, clean environment. |

Ensure the accuracy and longevity of your electrochemical research with the right equipment and expertise. KINTEK specializes in high-quality lab equipment and consumables, serving the precise needs of laboratories. Our team can help you select the perfect electrodes and provide guidance on best practices for maintenance. Protect your investment and your data—contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Gold Electrochemical Sheet Electrode Gold Electrode

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

People Also Ask

- What are the standard specifications for platinum wire and rod electrodes? Select the Right Form Factor for Your Experiment

- How does a platinum electrode and Ag/AgCl reference electrode monitor aluminum foil leaching? Precision Redox Control

- Why are platinized titanium anodes an ideal alternative to pure platinum? Save 36x in Kolbe Electrolysis Scale-up

- Why is a Saturated Calomel Electrode (SCE) used as a reference electrode in microbial fuel cell research?

- What are the features of the Lead Dioxide-Titanium Oxygen Evolution Electrode? High Oxidizing Power & Durability

- Which polishing cloths should be used with specific sizes of alumina powder? Match Cloth to Powder for a Perfect Finish

- What is a key environmental restriction for using platinum electrodes? Avoid Lithium to Prevent Corrosion

- What is the recommended maintenance for the filling solution of a reference electrode? A Guide to Stable & Accurate Readings