Proper maintenance of an acrylic electrolytic cell hinges on a disciplined routine that respects the material's unique properties. This involves gentle handling to prevent scratches, cleaning with appropriate non-corrosive solvents, regular inspection of the cell body and electrodes, and ensuring all components are stored in a dry, moisture-free environment.

An acrylic cell offers excellent optical clarity but demands greater care than its glass counterparts. Its primary vulnerabilities are its soft surface, which scratches easily, and its sensitivity to certain chemicals. Your maintenance strategy must therefore be built around preventing both physical abrasion and chemical degradation.

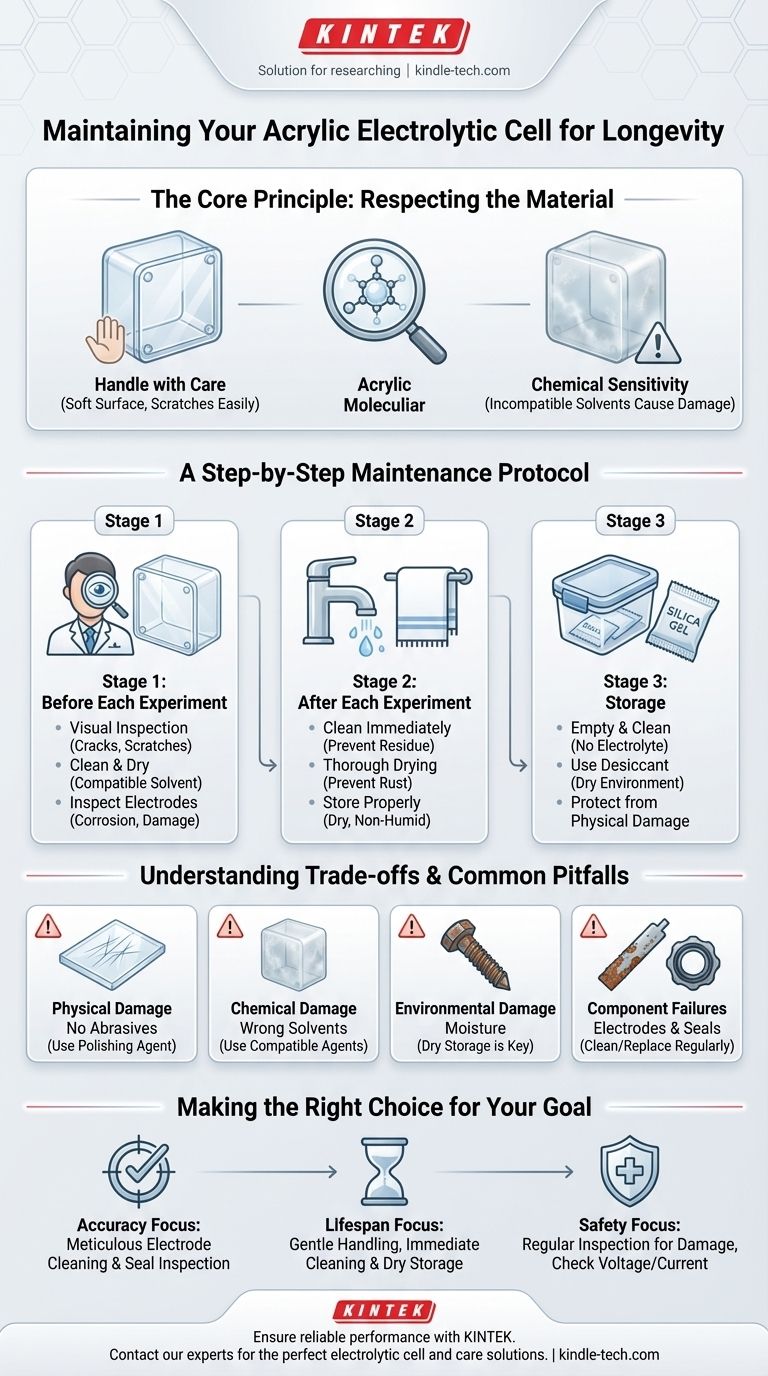

The Core Principle: Respecting the Material

Acrylic is chosen for its transparency, impact resistance, and cost-effectiveness. However, it is not glass. Understanding its inherent limitations is the first step toward extending its life.

The Vulnerability of Acrylic

The surface hardness of acrylic is relatively low. This makes it highly susceptible to scratches and abrasions from routine handling if care is not taken.

Chemical Sensitivity

Unlike borosilicate glass, acrylic can be damaged, clouded, or weakened by exposure to incompatible solvents. Always verify chemical compatibility before introducing new substances to the cell.

A Step-by-Step Maintenance Protocol

A consistent routine is the most effective way to ensure the cell's longevity and the accuracy of your experiments. This protocol should cover every phase of use.

Before Each Experiment

First, perform a visual inspection. Check the acrylic body for any cracks, deep scratches, or signs of chemical clouding.

Ensure the cell is clean. If needed, clean it with a suitable solvent to remove any grease or impurities, rinse thoroughly with distilled water, and allow it to air dry completely.

Inspect the electrodes for any signs of corrosion, contamination, or physical damage. A compromised electrode surface will compromise your results.

After Each Experiment

Clean the cell immediately after use. This prevents residual electrolytes or chemical products from drying onto the surfaces and causing corrosion or contamination.

Dry all components thoroughly. Pay special attention to metal parts, such as screws, to prevent rust.

Store the cell and its electrodes properly. Place them in a clean, dry, and non-humid environment to prevent moisture-related damage.

Understanding the Trade-offs and Common Pitfalls

Choosing acrylic involves accepting specific trade-offs. Being aware of the common failure modes allows you to prevent them proactively.

Physical Damage: The Enemy is Abrasion

Never use abrasive cleaners or rough cloths on the acrylic body. Minor scratches can often be removed with a polishing agent specifically designed for acrylic. Handle the cell gently to avoid collisions with hard objects.

Chemical Damage: Choosing the Right Solvents

Using the wrong cleaning solvent is a common and costly mistake. Aggressive or corrosive solvents can cause crazing (a network of fine cracks) or fogging of the acrylic. Always use a known, compatible, non-corrosive cleaning agent.

Environmental Damage: The Importance of Storage

For long-term storage, empty the electrolyte and ensure the cell is perfectly clean and dry. Placing a desiccant, like silica gel, inside the storage container can help maintain a dry environment and prevent degradation.

Component-Specific Failures

Electrodes can become contaminated or oxidized, affecting performance. Regularly clean noble metal electrodes in a dilute acid and store oxidation-prone metals in a protective, oxygen-free environment.

Seals are also a critical failure point. Regularly inspect all sealing components for signs of aging or damage and replace them immediately to prevent leaks.

Making the Right Choice for Your Goal

Your maintenance focus may shift slightly depending on your primary objective.

- If your primary focus is experimental accuracy: Prioritize meticulous electrode cleaning and regular inspection of all seals to prevent leaks or cross-contamination.

- If your primary focus is maximizing the cell's lifespan: Emphasize gentle handling, immediate post-use cleaning, and proper moisture-free storage.

- If your primary focus is operational safety: Make regular inspection for cracks or damage your top priority, and never exceed the cell's rated voltage and current.

Ultimately, a disciplined maintenance routine transforms your electrolytic cell from a consumable item into a reliable, long-term scientific instrument.

Summary Table:

| Maintenance Phase | Key Action | Purpose |

|---|---|---|

| Before Use | Visual inspection; clean with compatible solvent | Ensure cell integrity and remove contaminants |

| After Use | Immediate cleaning; thorough drying | Prevent chemical residue and corrosion |

| Storage | Store in a dry environment with desiccant | Protect from moisture and physical damage |

| Common Pitfalls | Avoid abrasive cleaners and incompatible solvents | Prevent scratching and chemical degradation |

Ensure your lab's electrolytic cells perform reliably for years to come. Proper maintenance is key to longevity and accurate results. KINTEK specializes in high-quality lab equipment and consumables, offering the right tools and expert advice to keep your experiments running smoothly.

Contact our experts today to find the perfect electrolytic cell and learn more about our comprehensive care solutions tailored to your laboratory's needs.

Visual Guide

Related Products

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

People Also Ask

- What is the purpose of the double-layer structure in the H-type electrolytic cell? Achieve Precise Thermal Control

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- What are the standard opening specifications for an H-type exchangeable membrane electrolytic cell? Asymmetrical Ports for Precise Electrochemistry

- What is the structure of an H-type exchangeable membrane electrolytic cell? A Guide to Precise Electrochemical Separation

- What is the typical experimental system used with a double-layer water-bath electrolytic cell? Achieve Precise Electrochemical Control