The most common method for regenerating activated carbon is a high-temperature thermal process designed to burn off and destroy the components that have been adsorbed onto its surface. This process is typically executed in three distinct stages, each involving progressively higher temperatures to fully restore the carbon's porous structure and adsorptive capacity.

Activated carbon regeneration is a process of reversing adsorption to restore the material's effectiveness. While thermal regeneration is the industry standard, it involves a trade-off between the cost of the process and the inevitable loss of material and performance with each cycle.

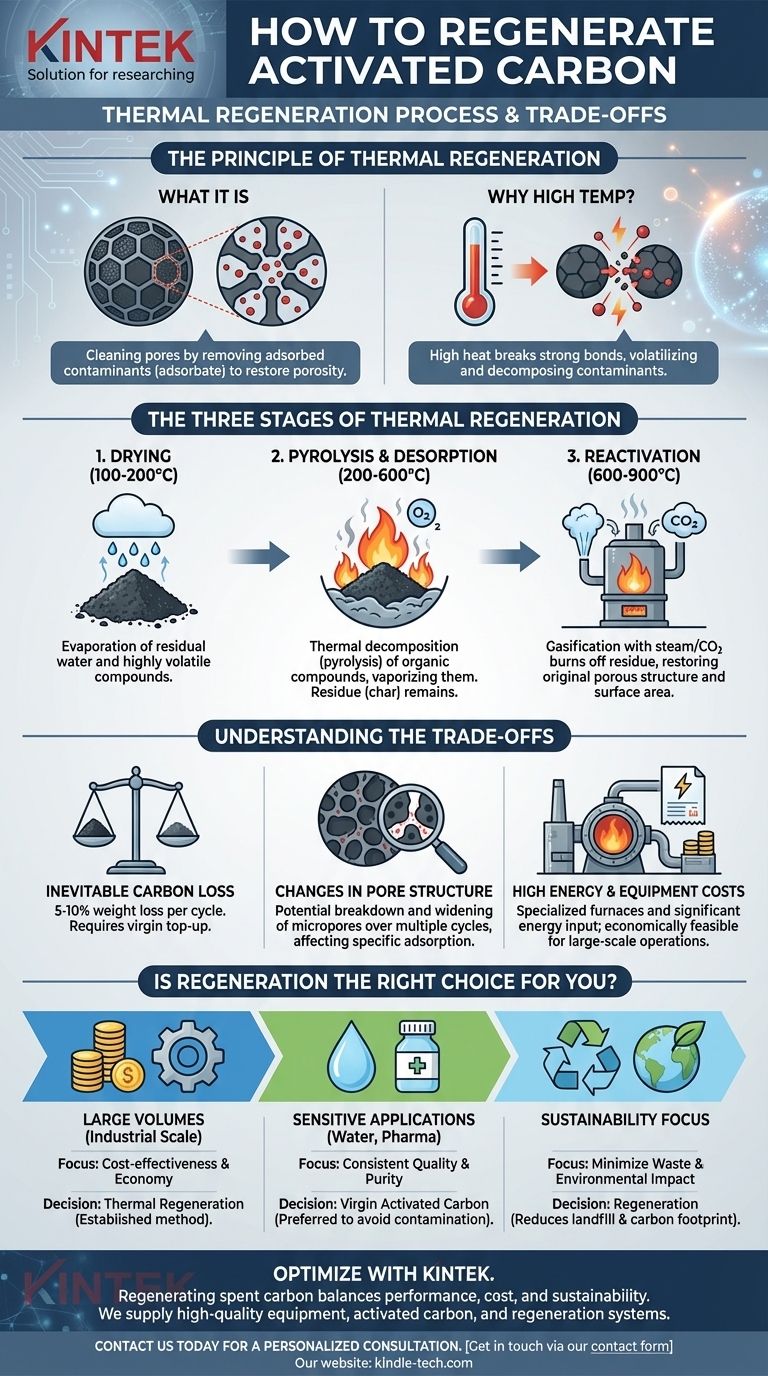

The Principle of Thermal Regeneration

What is Activated Carbon Regeneration?

Activated carbon works by providing a vast internal surface area, composed of millions of microscopic pores, where contaminants get trapped. Over time, these pores become saturated, rendering the carbon ineffective.

Regeneration is the process of cleaning out these pores by removing the adsorbed contaminants, known as the adsorbate. The goal is to restore the carbon's porosity so it can be reused.

Why High Temperature is Essential

The bonds holding contaminants to the carbon surface can be strong. Thermal regeneration uses high heat as the primary mechanism to provide the energy needed to break these bonds.

This process essentially volatilizes and then thermally decomposes the adsorbed contaminants within a controlled environment, clearing the pathways to the internal pore network.

The Three Stages of Thermal Regeneration

While specifics can vary based on the original carbon material and the type of contaminants, the thermal process generally follows three key phases.

Stage 1: Drying

The first step involves heating the spent carbon to approximately 100-200°C. The primary purpose of this stage is to evaporate any residual water held within the carbon's pore structure.

Some of the most highly volatile organic compounds may also be desorbed and vaporized during this initial drying phase.

Stage 2: Pyrolysis and Desorption

Next, the temperature is increased significantly, typically in the range of 200-600°C, in an oxygen-limited environment. This is the main desorption stage.

The heat causes the adsorbed organic compounds to break down (pyrolysis) and vaporize, freeing them from the carbon surface. The resulting gases are removed, leaving behind a layer of carbonized residue, or "char," within the pores.

Stage 3: Reactivation and Gasification

In the final and hottest stage, the temperature is raised above 600°C (often to 800-900°C). An oxidizing agent, typically steam or carbon dioxide, is introduced into the furnace.

This agent selectively reacts with the carbonized residue left behind in the previous stage (gasification), clearing out the pores and restoring the original porous structure. This step is critical for recovering the high surface area that gives activated carbon its adsorptive power.

Understanding the Trade-offs

Regeneration is not a perfect process. It's essential to understand the inherent limitations and costs before committing to it.

Inevitable Carbon Loss

Each thermal regeneration cycle is an aggressive process that burns away not only the contaminant char but also a small amount of the activated carbon itself.

This results in a material loss of 5-10% by weight with each cycle. The regenerated carbon must be topped up with virgin material to maintain the required volume.

Changes in Pore Structure

The high temperatures can also subtly alter the physical structure of the carbon. Over multiple cycles, this can lead to a breakdown of the material, generating more fine particles and potentially widening the micropores.

This structural change can reduce the carbon's effectiveness for adsorbing specific target molecules that rely on a particular pore size.

High Energy and Equipment Costs

Thermal regeneration requires specialized, high-temperature furnaces (like rotary kilns or multiple hearth furnaces) and significant energy input to operate.

These capital and operational expenses mean that regeneration is typically only economically feasible for large-scale industrial operations. For smaller applications, replacing the spent carbon is often more cost-effective.

Is Regeneration the Right Choice for You?

The decision to regenerate versus replace depends entirely on your operational scale, budget, and performance requirements.

- If your primary focus is managing large volumes of spent carbon economically: Thermal regeneration is the most established and cost-effective method for industrial-scale applications.

- If your primary focus is on sensitive applications like drinking water or pharmaceuticals: Using virgin activated carbon is often preferred to guarantee consistent quality and avoid any risk of contamination from previous cycles.

- If your primary focus is sustainability and minimizing waste: Regeneration offers a significant environmental benefit by reducing landfill disposal and the carbon footprint associated with producing new material.

Ultimately, choosing to regenerate activated carbon is a strategic decision that balances operational cost, environmental responsibility, and the performance demands of your specific process.

Summary Table:

| Stage | Temperature Range | Key Process | Purpose |

|---|---|---|---|

| 1. Drying | 100-200°C | Evaporation | Remove water and volatile compounds |

| 2. Pyrolysis & Desorption | 200-600°C | Thermal decomposition (low oxygen) | Vaporize and break down adsorbed organics |

| 3. Reactivation | 600-900°C | Gasification (with steam/CO₂) | Burn off residue to restore porosity |

Optimize your activated carbon management with KINTEK.

Regenerating spent carbon is a strategic decision that balances performance, cost, and sustainability. Whether you operate at an industrial scale and need to reduce disposal costs, or require virgin carbon for sensitive applications like pharmaceuticals, KINTEK has the solution.

We specialize in supplying high-quality laboratory equipment and consumables, including activated carbon and the systems needed for its effective use and regeneration. Our expertise helps you maximize efficiency and minimize waste.

Contact us today to discuss your specific needs and let our experts guide you to the most cost-effective and reliable solution for your process. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the principles of a rotary kiln? Master the Mechanics of High-Temperature Processing

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process

- What is the temperature for activated carbon regeneration? Key Ranges from 220°C to 900°C

- What temperature is needed for porcelain? A Guide to Cone 6 and Cone 10 Firing