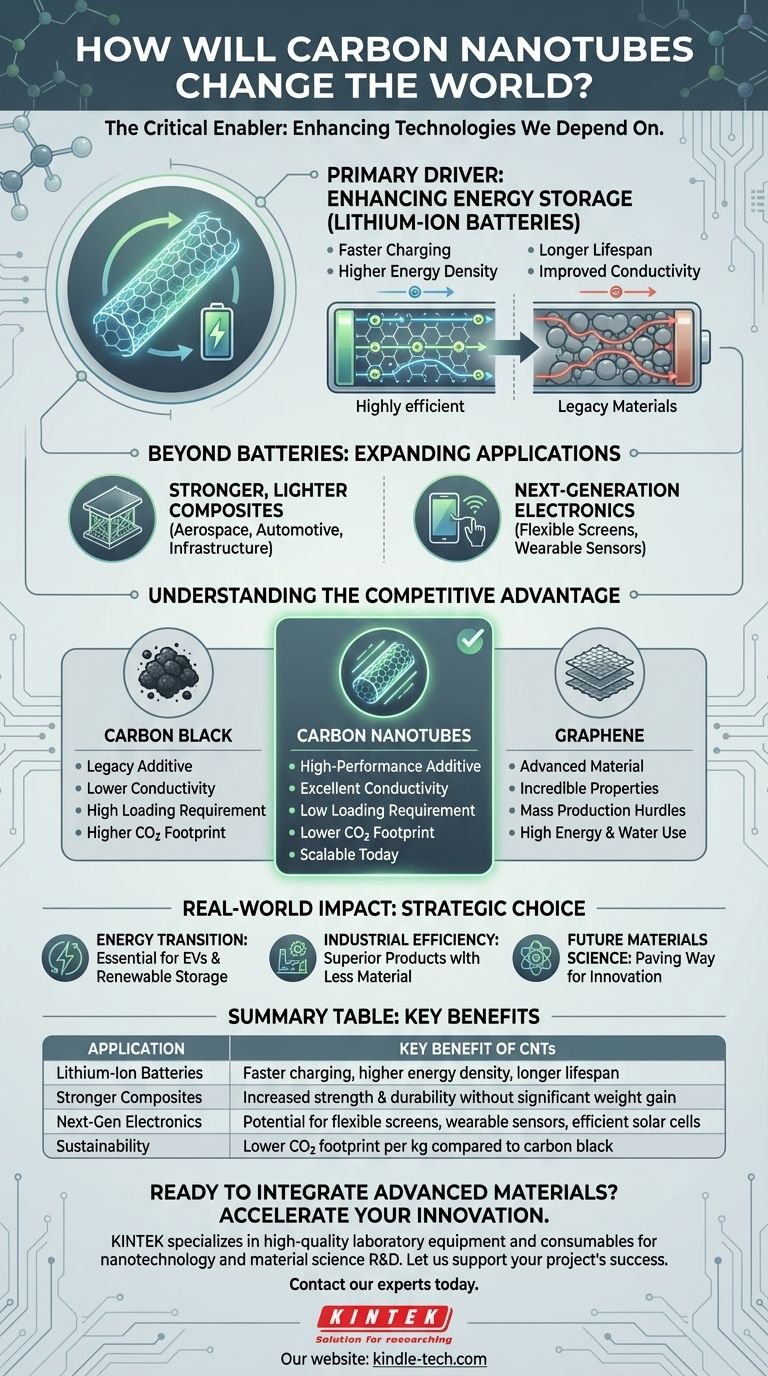

At their core, carbon nanotubes will change the world not by creating fantastical new devices overnight, but by making the technologies we already depend on—especially batteries—significantly more powerful, durable, and sustainable. Their immediate, tangible impact is as a high-performance additive that enhances existing materials, rather than as a standalone wonder material.

The true revolution of carbon nanotubes is in their role as a critical enabler. They are quietly making green technologies more efficient and commercially viable by outperforming older materials like carbon black while being more scalable today than newer materials like graphene.

The Primary Driver: Enhancing Energy Storage

The most significant and immediate impact of carbon nanotubes (CNTs) is within lithium-ion batteries, the power source for everything from electric vehicles to smartphones.

Why Batteries Need a Boost

Modern batteries face a constant battle against their own physical limitations. Key challenges include slow charging speeds, limited energy density (how much power they can hold), and degradation over time.

The Role of CNTs as Conductive Additives

CNTs are almost unimaginably small, strong, and electrically conductive. When a tiny amount is mixed into a battery's electrode materials (the cathode and anode), they form a highly efficient electrical network.

This network acts like a superhighway for electrons, allowing energy to move in and out of the battery with far less resistance.

The Tangible Benefits for Batteries

This improved conductivity directly translates to real-world performance gains. Batteries with CNTs can be charged faster, last for more cycles, and store more energy in the same amount of space. This means longer-range electric vehicles and more reliable grid-scale energy storage.

Beyond Batteries: Expanding Applications

While batteries are the main market, the unique properties of CNTs are creating value in other sectors, particularly in advanced materials.

Stronger, Lighter Composites

When added to materials like concrete or polymers, CNTs can drastically increase strength and durability without adding significant weight. This opens the door for longer-lasting infrastructure and lighter components in aerospace and automotive manufacturing.

Next-Generation Electronics

CNTs are also being explored for use in transparent, conductive films. This could lead to the development of flexible screens, wearable sensors, and more efficient solar cells, though these applications are generally at an earlier stage than their use in batteries.

Understanding the Competitive Advantage

To grasp why CNTs are gaining traction, it's essential to compare them to the alternatives they are replacing or competing with.

The Problem with Carbon Black

Carbon black is the traditional conductive additive used in batteries and composites. However, it is far less conductive than CNTs. To achieve a desired effect, manufacturers must use a much larger amount of it.

This high loading requirement not only adds weight but also displaces active material in a battery, reducing its overall energy capacity. Furthermore, its production generally carries a higher carbon footprint.

The Graphene Challenge

Graphene is another advanced carbon material with incredible properties. However, its path to mass production faces significant hurdles related to energy consumption, high water usage, and the need for harsh chemicals.

Currently, carbon nanotubes offer a more mature, scalable, and environmentally favorable manufacturing process, making them the more practical choice for many large-scale industrial applications today.

The Sustainability Angle

This is the critical differentiator. CNTs enable better performance in green technologies like batteries while having a lower CO2 footprint per kilogram compared to carbon black. This combination of high performance and better sustainability is the engine driving their adoption.

How This Translates to Real-World Impact

The adoption of carbon nanotubes is a strategic choice based on clear performance and environmental trade-offs. Their impact is felt by improving the efficiency of the technologies that will define our future.

- If your primary focus is the energy transition: CNTs are a key enabling material for better batteries, which are essential for the widespread adoption of electric vehicles and renewable energy storage.

- If your primary focus is industrial efficiency: Using CNTs allows manufacturers to create superior products with less material and a more favorable environmental profile compared to legacy additives.

- If your primary focus is future materials science: CNTs serve as a leading example of how nanomaterials are moving from the lab to large-scale commercial reality, paving the way for further innovation.

Ultimately, carbon nanotubes are a powerful force for incremental, yet profound, technological evolution.

Summary Table:

| Application | Key Benefit of CNTs |

|---|---|

| Lithium-Ion Batteries | Faster charging, higher energy density, longer lifespan |

| Stronger Composites | Increased strength & durability without significant weight gain |

| Next-Gen Electronics | Potential for flexible screens, wearable sensors, efficient solar cells |

| Sustainability | Lower CO2 footprint per kg compared to carbon black |

Ready to integrate advanced materials into your products?

KINTEK specializes in providing high-quality laboratory equipment and consumables essential for research and development in nanotechnology and material science. Whether you are developing next-generation batteries, stronger composites, or innovative electronics, having the right tools is critical.

Let us help you accelerate your innovation. Contact our experts today to discuss how our solutions can support your specific laboratory needs and contribute to your project's success.

Visual Guide

Related Products

- Aluminum Foil Current Collector for Lithium Battery

- High Purity Zinc Foil for Battery Lab Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- How to check the power of a lithium-ion battery? Master the difference between charge level and battery health.

- Why is carbon coating important? Boost Battery Performance and Longevity

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- How do you test the capacity of a lithium-ion battery? A Guide to Accurate Measurement