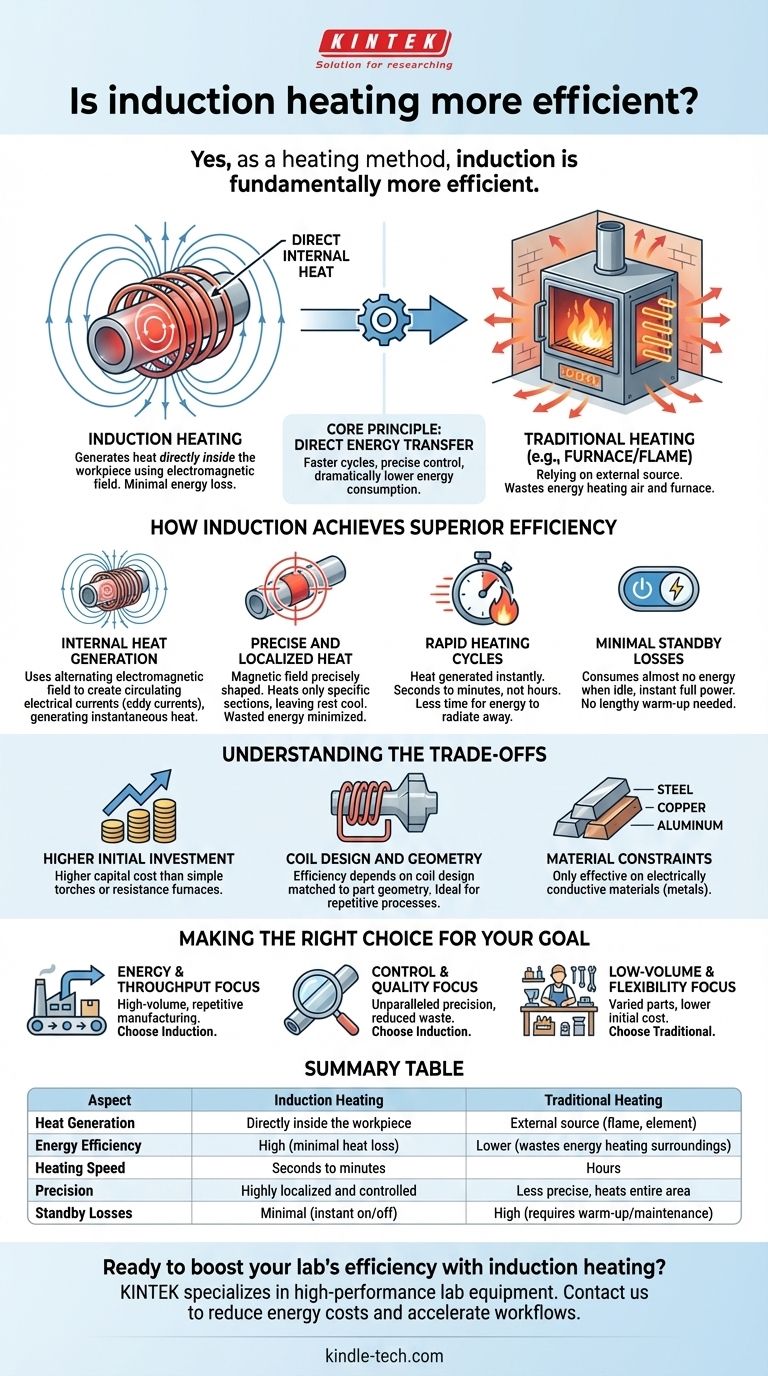

Yes, as a heating method, induction is fundamentally more efficient. This is because induction heating generates heat directly inside the workpiece using an electromagnetic field, rather than relying on an external heat source like a flame or heating element. Traditional methods waste a significant amount of energy heating the surrounding air and the furnace itself, while induction transfers energy with minimal loss.

The core principle behind induction's superior efficiency is its method of direct energy transfer. By generating heat within the material itself, it bypasses the slow and wasteful process of heat conduction, leading to faster cycles, precise control, and dramatically lower energy consumption.

How Induction Achieves Superior Efficiency

Understanding the mechanism of induction reveals why it stands apart from conventional heating. It’s not just an incremental improvement; it’s a different paradigm of energy transfer.

Internal Heat Generation

Traditional furnaces and torches work by conduction and convection. They create a hot environment, and that heat slowly soaks into the part from the outside in.

Induction heating uses an alternating electromagnetic field to create circulating electrical currents (eddy currents) inside the conductive material. The material's natural resistance to these currents generates precise, instantaneous heat from within.

Precise and Localized Heat

A significant source of inefficiency in conventional heating is wasted energy. A furnace heats its own walls and the entire chamber just to heat the part inside.

With induction, the magnetic field can be precisely shaped and targeted. This means you only heat the specific section of the part that requires it, leaving the rest of the material and the surrounding environment cool.

Rapid Heating Cycles

Because heat is generated instantly and internally, heating cycles are exceptionally fast—often taking seconds or minutes instead of hours.

This speed is a major component of its overall efficiency. Less time spent heating means less opportunity for energy to radiate away from the part, resulting in lower total energy consumption per part produced.

Minimal Standby Losses

An induction system consumes almost no energy when idle and reaches full power in an instant.

Conversely, a conventional furnace requires a lengthy warm-up period and is often left running between cycles to avoid delays, constantly burning energy just to maintain its temperature.

Understanding the Trade-offs

While highly efficient, induction heating is not a universal solution. Objectivity requires acknowledging its specific constraints and considerations.

Higher Initial Investment

Induction heating equipment typically carries a higher upfront capital cost compared to a simple torch setup or a basic resistance-coil furnace.

Coil Design and Geometry

The efficiency of an induction process is heavily dependent on the design of the induction coil, which must be carefully matched to the geometry of the part being heated. This makes it ideal for repetitive processes but less flexible for one-off jobs with varying shapes.

Material Constraints

The process works by inducing an electric current within the material. Therefore, it is only effective on electrically conductive materials, primarily metals like steel, copper, and aluminum.

Making the Right Choice for Your Goal

The "best" heating method depends entirely on the priorities of your application. Induction's efficiency is not just about saving energy; it's about improving the entire process.

- If your primary focus is minimizing energy costs and maximizing throughput: The rapid, direct heating of induction is the clear choice for high-volume, repetitive manufacturing.

- If your primary focus is process control and part quality: Induction offers unparalleled precision, reducing material warping, scaling, and defects, which leads to less waste.

- If your primary focus is low-volume work with varied parts: The flexibility and lower initial cost of traditional methods like a torch or furnace may be more practical despite their lower energy efficiency.

By understanding that induction's efficiency encompasses energy, speed, and material precision, you can select the optimal heating technology for your specific industrial process.

Summary Table:

| Aspect | Induction Heating | Traditional Heating |

|---|---|---|

| Heat Generation | Directly inside the workpiece | External source (flame, element) |

| Energy Efficiency | High (minimal heat loss) | Lower (wastes energy heating surroundings) |

| Heating Speed | Seconds to minutes | Hours |

| Precision | Highly localized and controlled | Less precise, heats entire area |

| Standby Losses | Minimal (instant on/off) | High (requires warm-up and maintenance) |

Ready to boost your lab's efficiency with induction heating?

KINTEK specializes in high-performance lab equipment, including induction heating systems designed for rapid, precise, and energy-efficient thermal processing. Whether you're in materials research, manufacturing, or quality control, our solutions help you reduce energy costs, accelerate workflows, and improve part quality.

Contact us today to explore how our induction heating technology can transform your lab's capabilities!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What are the advantages of a vacuum hot-press furnace? Superior Bonding for Diamond/Aluminum Composites

- Why must vacuum hot pressing equipment have high-tonnage pressure control for WC/Cu-Zr-Ti amorphous composites?

- What are the core advantages of using a vacuum hot pressing furnace for Cu/WC composites? Superior Density & Bonding