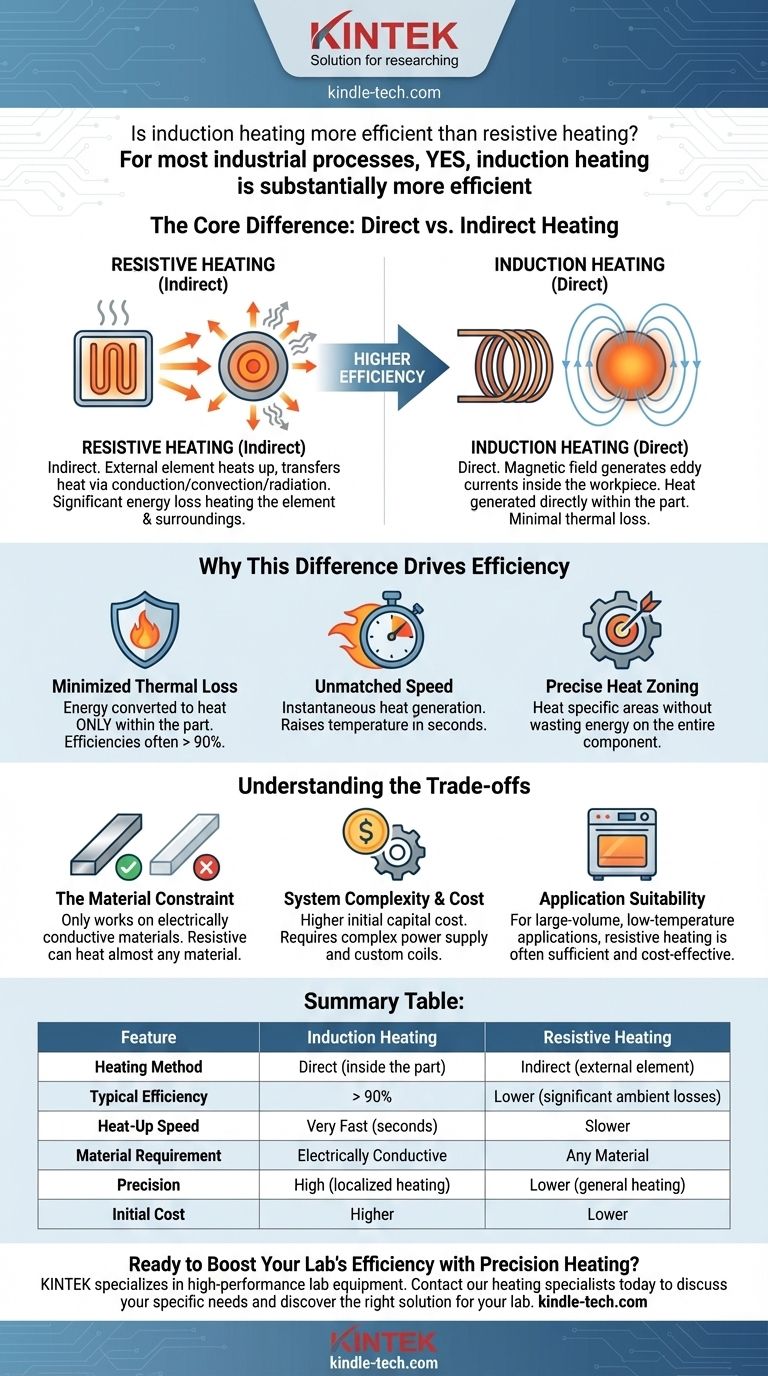

For most industrial processes, yes, induction heating is substantially more efficient than resistive heating. This efficiency advantage comes from its unique method of heat generation. Instead of heating an external element and waiting for that heat to transfer, induction heating uses a magnetic field to generate heat directly inside the workpiece itself.

The core difference lies in direct versus indirect heating. Resistive heating loses significant energy by heating the surrounding environment, while induction heating turns the workpiece into its own heat source, drastically minimizing thermal losses and improving process speed.

The Fundamental Difference: Direct vs. Indirect Heating

To understand the efficiency gap, you must first understand the fundamental difference in how these two methods deliver thermal energy.

How Resistive Heating Works (Indirect)

Resistive heating is a form of indirect heating. It works by passing an electrical current through a high-resistance material, known as a heating element.

This element gets extremely hot and then transfers its thermal energy to the target workpiece through conduction, convection, or radiation. Significant energy is lost heating the element itself and the surrounding air and structures.

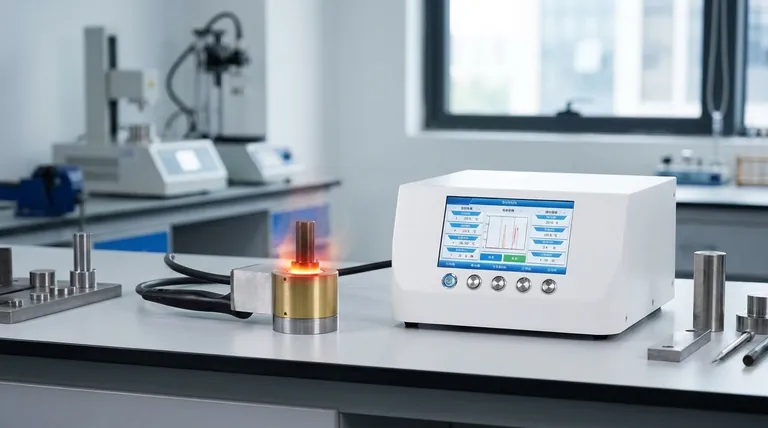

How Induction Heating Works (Direct)

Induction heating is a form of direct heating. It uses an alternating current flowing through a copper coil to generate a powerful, oscillating magnetic field.

When a conductive workpiece (like steel) is placed within this field, the field induces electrical currents—called eddy currents—directly within the metal. The material's natural resistance to these internal currents generates precise, rapid heat from the inside out.

Why This Difference Drives Efficiency

The move from an indirect to a direct heating method creates several key advantages that add up to significant energy and operational savings.

Minimized Thermal Loss

This is the single biggest factor. With resistive heating, much of the energy is wasted heating the air, insulation, and the heating element itself. With induction, nearly all the energy is converted to heat only within the part, leading to process efficiencies often exceeding 90%.

Unmatched Speed

Induction does not have to wait for an external element to warm up and transfer its heat. Heat generation is instantaneous and can be incredibly rapid, raising the temperature of a specific area by hundreds of degrees in seconds. This reduces overall energy-on time.

Precise Heat Zoning

The magnetic field can be shaped by the design of the induction coil. This allows you to heat a very specific area of a part—such as the tip of a tool or a single gear tooth—without wasting energy heating the entire component. This level of precision is nearly impossible with resistive methods.

Understanding the Trade-offs

While highly efficient, induction heating is not the universal solution. Its effectiveness is dependent on the application, and sometimes resistive heating is the more practical choice.

The Material Constraint

The primary limitation of induction is that it only works on electrically conductive materials, like metals. It cannot heat plastics, glass, ceramics, or other insulators. Resistive heating, by contrast, can heat almost any material.

System Complexity and Cost

Induction heating systems are more complex. They require a high-frequency power supply and a carefully designed copper coil, often custom-made for the specific part. This results in a higher initial capital cost compared to the simplicity and low cost of resistive heaters.

Application Suitability

For large-volume, low-temperature applications like a curing oven, the slow, gentle heat of a resistive system is often perfectly adequate and more cost-effective. The high speed of induction would be unnecessary and its precision an unused benefit.

Making the Right Choice for Your Goal

Selecting the correct technology requires matching its strengths to your primary objective.

- If your primary focus is maximum energy efficiency and speed: For conductive materials in repetitive processes like hardening, brazing, or forging, induction heating is the definitive choice.

- If your primary focus is low initial cost and material versatility: Resistive heating is the more practical and economical solution, especially for non-metals or general-purpose oven applications.

- If your primary focus is precise heat control on a specific zone: Induction offers unparalleled precision, minimizing energy waste and preventing damage to adjacent areas of a part.

Ultimately, understanding the core principle of direct versus indirect heat generation empowers you to select the technology that truly aligns with your operational and financial goals.

Summary Table:

| Feature | Induction Heating | Resistive Heating |

|---|---|---|

| Heating Method | Direct (inside the part) | Indirect (external element) |

| Typical Efficiency | > 90% | Lower (significant ambient losses) |

| Heat-Up Speed | Very Fast (seconds) | Slower |

| Material Requirement | Electrically Conductive | Any Material |

| Precision | High (localized heating) | Lower (general heating) |

| Initial Cost | Higher | Lower |

Ready to Boost Your Lab's Efficiency with Precision Heating?

KINTEK specializes in high-performance lab equipment, including advanced heating solutions for industrial and research applications. Whether you need the rapid, efficient performance of induction heating or the versatile simplicity of resistive systems, our experts can help you select the ideal technology to enhance your process, save energy, and improve results.

Contact our heating specialists today to discuss your specific needs and discover the right solution for your lab.

Visual Guide

Related Products

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How hot does a magnetic induction heater get? Achieve Precise Temperatures from 100°C to 3000°C

- What are the disadvantages of induction soldering? Key Limitations for Your Production Process

- How does induction furnace operate? Master the Science of Efficient, Clean Metal Melting

- Does induction heating only work on metals? Unlocking the Science for Non-Metals

- Can you melt metal to reuse it? Unlock the Secrets of Metal Casting and Recycling

- What is the history of induction furnace? From Faraday's Discovery to Modern Melting Power

- How hot can an induction heater get? Achieve up to 3000°C for precise industrial heating

- What is high frequency induction heating? Master Precision Surface Hardening & Brazing