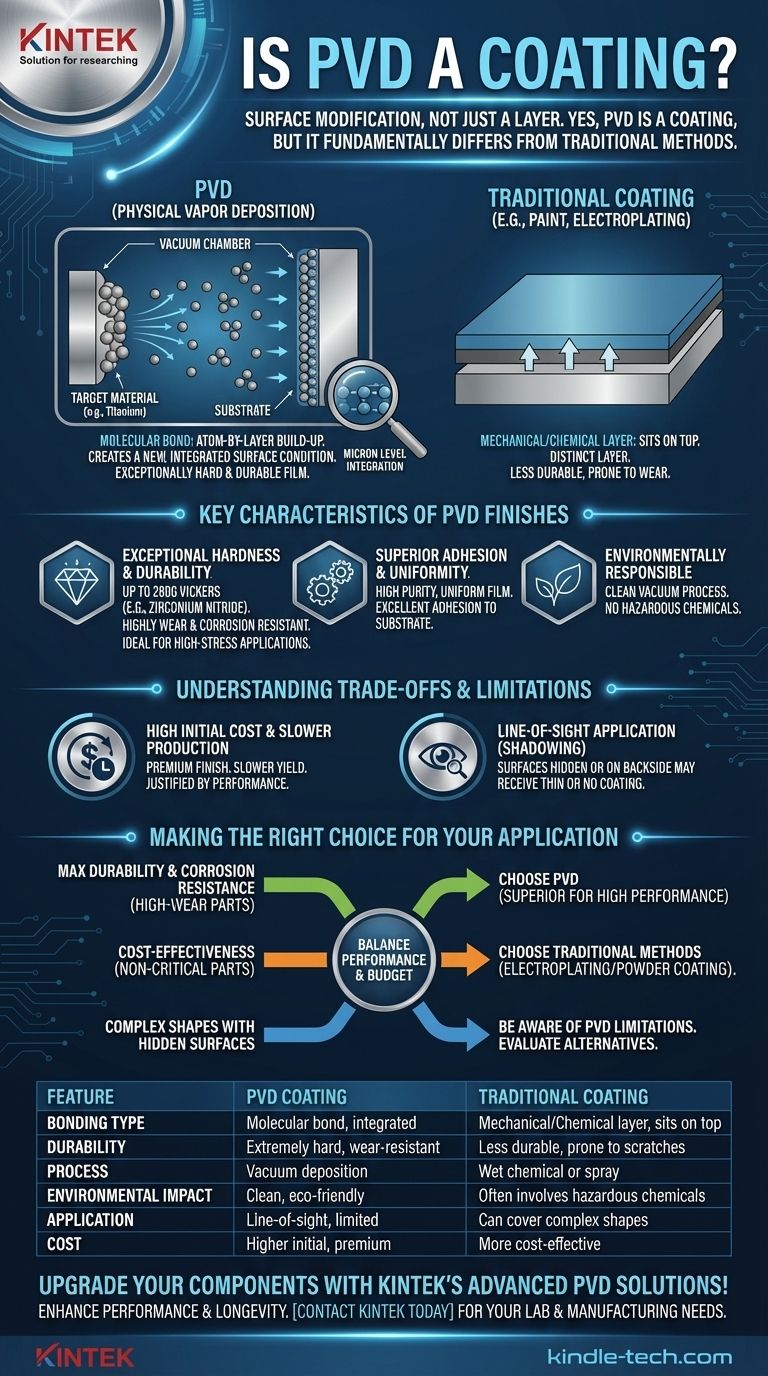

Yes, PVD is a type of coating, but it fundamentally differs from traditional methods like painting or electroplating. The term Physical Vapor Deposition (PVD) describes a process where a solid material is vaporized in a vacuum and then bonded to a substrate at the molecular level, creating an extremely thin, durable film. It is more accurately described as a surface modification than a simple added layer.

The crucial distinction is that PVD doesn't just sit on top of the material; it creates a new, integrated surface condition. This molecular bond is what gives PVD finishes their exceptional hardness and durability, setting them apart from conventional coatings.

How PVD Differs from Traditional Coatings

To grasp the value of PVD, you must understand how it changes the surface itself, rather than simply covering it.

It's a Process, Not a Material

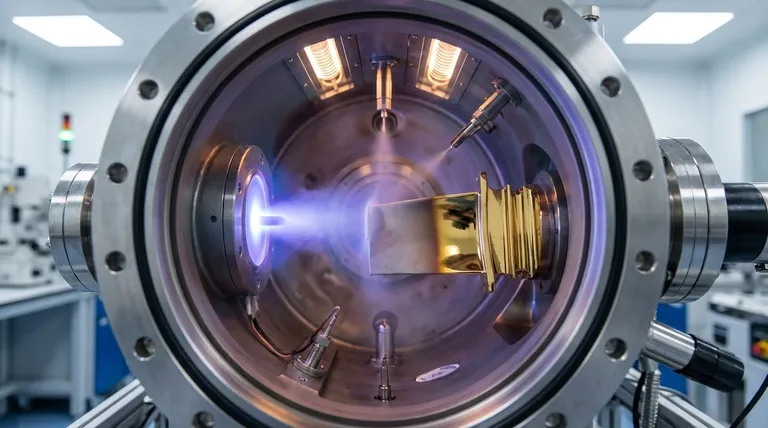

PVD stands for Physical Vapor Deposition. It is a vacuum deposition method that can use a wide range of materials to create the coating.

The process involves vaporizing a solid material (like titanium or zirconium nitride) inside a vacuum chamber. This vapor then travels and condenses, atom by atom, onto the target object, forming a thin, tightly bonded film.

Molecular Bonding vs. Simple Layering

Traditional coatings, like paint, form a distinct mechanical layer on top of a surface. Electroplating creates a chemical bond but still adds a relatively thick layer.

PVD, by contrast, forms a molecular bond at the micron level. This creates a new surface with altered physical properties, rather than just covering the old one. The finish is so thin and integrated that it's often translucent.

The Result: A High-Performance Surface

This process results in a finish that is exceptionally hard and wear-resistant. For example, a PVD finish using Zirconium Nitride can achieve a hardness of 2800 Vickers—significantly harder than most steels.

This changes the character of the base material, making it far more resistant to scratches, abrasion, and corrosion.

Key Characteristics of PVD Finishes

The unique nature of the PVD process imparts several key advantages that make it the preferred choice for high-performance applications.

Exceptional Hardness and Durability

PVD coatings are generally much harder and more corrosion-resistant than finishes applied by electroplating. This makes them ideal for aerospace, medical, and automotive components that endure high stress.

Superior Adhesion and Uniformity

Because the coating is built atom by atom in a vacuum, the resulting film is highly pure, uniform, and possesses excellent adhesion to the substrate.

For certain substrates, a base layer of nickel or chromium may be used to enhance this adhesion, though it isn't always required.

Environmentally Responsible

Compared to traditional electrochemical processes like chrome plating, which involve hazardous chemicals, PVD is a clean, environmentally friendly process.

Understanding the Trade-offs and Limitations

While powerful, PVD is not the right solution for every situation. Its high-performance nature comes with specific trade-offs.

High Initial Cost and Slower Production

The equipment is expensive, and the process has a slower rate of yield than many bulk finishing methods. This makes PVD a premium option typically reserved for applications where performance justifies the cost.

Line-of-Sight Application

The deposition process works in a "line-of-sight." This means surfaces that are hidden or on the backside of a part may receive a much thinner coating or none at all, an effect known as shadowing.

Properly loading parts into the PVD reactor is complex and critical to ensure even coverage, often requiring a lower density of parts per batch.

Making the Right Choice for Your Application

Selecting a surface finish requires balancing performance requirements with budget and manufacturing constraints.

- If your primary focus is maximum durability and corrosion resistance: PVD is the superior choice for high-wear parts where failure is not an option.

- If your primary focus is cost-effectiveness on non-critical parts: Traditional electroplating or powder coating may be a more practical and economical solution.

- If you need to coat complex shapes with many hidden surfaces: Be aware of PVD's line-of-sight limitations and evaluate if another process can provide more consistent coverage.

By understanding PVD as a surface modification process, you can accurately assess its unique strengths and decide where its high performance justifies the investment.

Summary Table:

| Feature | PVD Coating | Traditional Coating (e.g., Paint/Electroplating) |

|---|---|---|

| Bonding Type | Molecular bond, integrated surface | Mechanical layer or chemical bond, sits on top |

| Durability | Extremely hard, wear-resistant (e.g., 2800 Vickers) | Less durable, prone to scratches and wear |

| Process | Vacuum deposition, atom-by-layer build-up | Wet chemical or spray application |

| Environmental Impact | Clean, eco-friendly process | Often involves hazardous chemicals |

| Application | Line-of-sight, limited to visible surfaces | Can cover complex shapes and hidden areas |

| Cost | Higher initial cost, premium finish | More cost-effective for non-critical parts |

Upgrade your components with KINTEK's advanced PVD solutions!

As a leading provider of lab equipment and consumables, KINTEK specializes in high-performance PVD coatings that transform surfaces at the molecular level. Our PVD processes deliver exceptional hardness, corrosion resistance, and durability—perfect for aerospace, medical, and automotive applications where failure is not an option.

Let us help you enhance your product's performance and longevity. Contact KINTEK today to discuss your specific needs and discover how our PVD expertise can benefit your laboratory or manufacturing process!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding