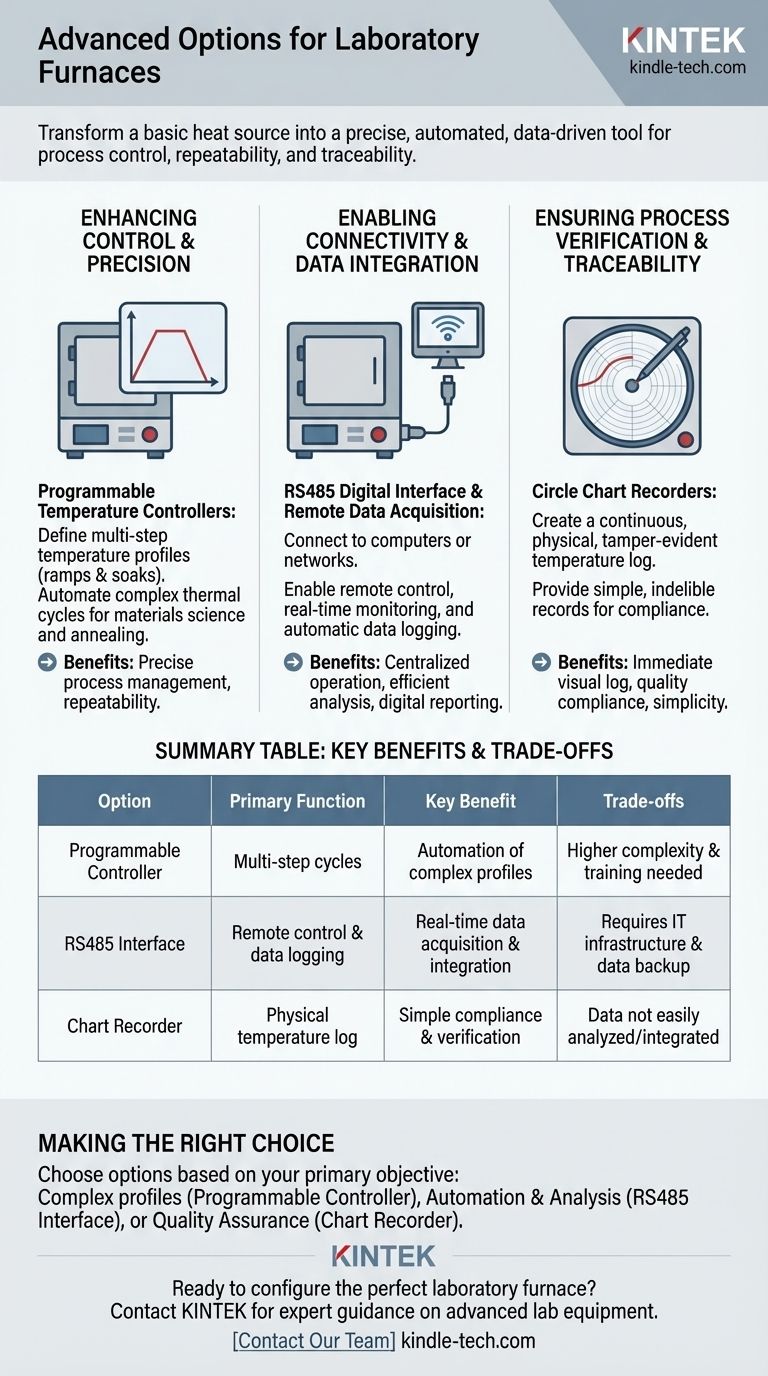

Beyond simple heating, a modern laboratory furnace can be transformed into a precise, automated instrument by configuring it with advanced control and data logging options. These include programmable temperature controllers for complex heating cycles, an RS485 communications interface for remote control and data acquisition, and chart recorders for maintaining a permanent physical record of the process.

The core decision is not just about adding features, but about elevating the furnace from a basic heat source to a data-driven tool that ensures process control, repeatability, and traceability for your specific application.

Enhancing Control and Precision

The most fundamental upgrade involves moving beyond a simple "set-it-and-forget-it" temperature. True process control requires managing how the temperature changes over time.

Programmable Temperature Controllers

A standard controller holds a single temperature. A programmable controller allows you to define a multi-step temperature profile.

This means you can automate complex cycles involving ramps (heating/cooling at a specific rate) and soaks (holding a specific temperature for a set duration). This is critical for materials science, annealing, and other sensitive thermal processes.

Enabling Connectivity and Data Integration

For modern labs and industrial settings, integrating equipment into a central system is key for efficiency and analysis. A communications interface is the gateway to achieving this.

The RS485 Digital Interface

An RS485 interface is a robust communication port that allows the furnace to connect to a computer or a larger network.

This physical connection is what enables the furnace to send and receive digital information, moving it beyond a standalone device.

Remote Control and Data Acquisition

Once connected via RS485, you can remotely operate the furnace and, more importantly, acquire data in real-time.

This allows an operator to start, monitor, and stop processes from a central control room and automatically log temperature data to a computer for analysis, reporting, and archiving.

Ensuring Process Verification and Traceability

For many applications, especially in quality control or regulated industries, proving that a process was run correctly is as important as the process itself.

The Circle Chart Recorder

A circle chart recorder is a device that provides a continuous, physical record of the furnace's temperature over a specific time period.

It uses a pen to draw a temperature graph on a rotating circular paper chart. This creates a simple, tamper-evident visual log of the entire heat treatment cycle.

While digital logging is more flexible for analysis, a physical chart is often valued for its simplicity and is sometimes required for specific quality compliance standards.

Understanding the Trade-offs

Adding advanced options provides powerful capabilities, but it's important to weigh them against practical considerations.

Complexity vs. Simplicity

Programmable controllers and remote software add layers of operational complexity. Ensure your team has the training to utilize these features effectively, as an improperly programmed cycle can ruin a sample.

Digital vs. Analog Records

Digital data acquisition (via RS485) is searchable, easy to analyze, and simple to store. However, it requires robust IT infrastructure and data backup protocols.

A physical chart recorder provides an immediate, indelible record that requires no network, but the data is not easily analyzed or integrated into digital reports.

Cost and Justification

Each of these options adds to the furnace's initial purchase price. The investment must be justified by the specific need for process automation, data integrity, or regulatory compliance.

Making the Right Choice for Your Goal

The ideal configuration depends entirely on your primary objective for the furnace.

- If your primary focus is running complex thermal profiles: A programmable temperature controller is the essential upgrade.

- If your primary focus is automation and digital data analysis: The RS485 interface is the critical component for computer integration.

- If your primary focus is quality assurance and compliance: A chart recorder or a validated digital data acquisition system provides the necessary process traceability.

Choosing the right options transforms your furnace from a simple piece of equipment into a strategic asset for reliable and verifiable results.

Summary Table:

| Advanced Option | Primary Function | Key Benefit |

|---|---|---|

| Programmable Controller | Defines multi-step heating/cooling cycles | Enables automation of complex thermal profiles |

| RS485 Interface | Connects furnace to a computer/network | Allows remote control and real-time data logging |

| Chart Recorder | Creates a physical, tamper-evident temperature log | Provides simple compliance and process verification |

Ready to configure the perfect laboratory furnace for your specific needs? At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to enhance your laboratory's capabilities. Whether you require precise programmable controllers, seamless data integration, or compliance-ready traceability, our experts will help you select the right options to achieve reliable, repeatable results. Contact our team today to discuss your application and let us help you transform your furnace into a strategic asset!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Tube Furnace

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing