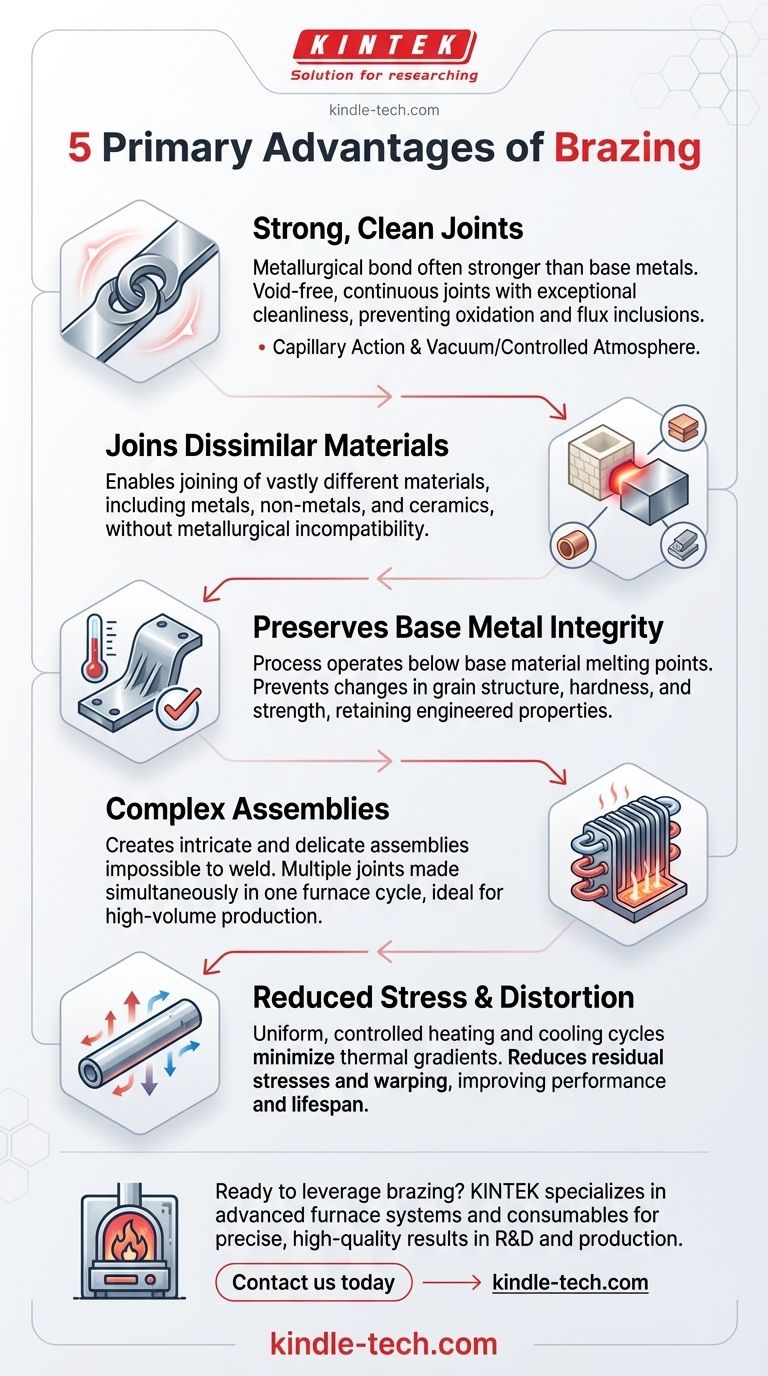

The five primary advantages of brazing are its ability to create strong, clean joints, join dissimilar materials, maintain the integrity of the base metals by using low heat, create complex assemblies with multiple joints simultaneously, and reduce residual stress and distortion. These benefits stem from the process of heating a filler metal above its melting point and drawing it into a joint via capillary action, all without melting the base materials themselves.

Brazing is fundamentally a low-temperature, non-fusion joining process. This core principle is the source of its greatest strengths: preserving the properties of the parent materials while creating exceptionally strong, clean, and intricate joints that are often impossible to achieve with conventional welding.

The Principle: Why Lower Temperatures Matter

Brazing operates on a fundamentally different principle than welding. Instead of melting the base materials to fuse them, it uses a filler metal with a lower melting point to create a metallurgical bond.

Preserving Base Metal Integrity

The heat used in brazing is below the melting point of the materials being joined. This is the most critical distinction.

By avoiding the melting of the base materials, brazing prevents the significant changes in grain structure, hardness, and strength that can occur during fusion welding. This ensures the components retain their engineered properties.

Reducing Thermal Stress and Distortion

Brazing uses uniform, controlled heating and cooling cycles, often within a furnace. This minimizes the thermal gradients that cause parts to warp or distort.

Slow and even temperature changes significantly reduce the residual stresses locked into the assembly, improving the final product's mechanical performance and lifespan.

Achieving Superior Joint Quality and Strength

The quality of a brazed joint is often superior to that of the base metals it joins. This is a result of both the process environment and the nature of the bond itself.

The Power of Capillary Action

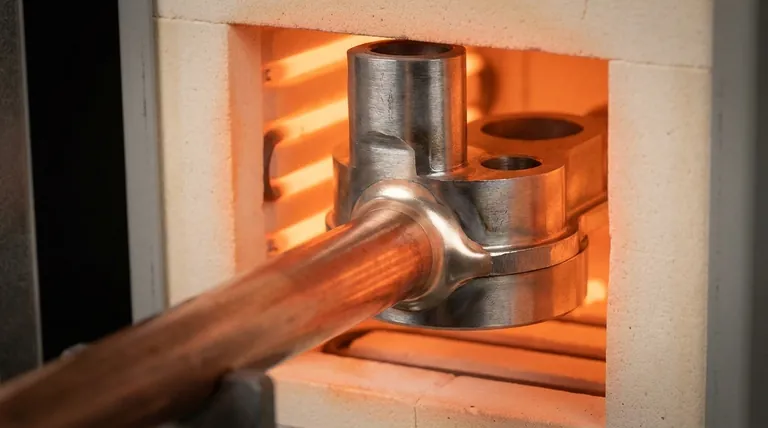

Brazing relies on capillary action to draw the molten filler metal into the tight-fitting gap between the two components.

This natural phenomenon ensures the filler metal is distributed completely and evenly throughout the entire joint, including long or inaccessible areas. The result is a void-free, continuous bond.

Creating High-Strength Joints

A properly designed brazed joint is stronger than the parent materials. The filler metal forms a metallurgical bond with the base materials, creating a new alloy at the interface.

When placed under load, the base metals will typically fail before the brazed joint does, demonstrating the exceptional strength of this bond.

Ensuring Exceptional Cleanliness

Modern methods like vacuum and controlled atmosphere furnace brazing create an extremely clean environment. This prevents oxidation during the heating cycle.

The result is a bright, clean assembly that often requires no post-process cleaning. More importantly, it eliminates the need for corrosive fluxes, preventing the risk of flux inclusions that could compromise the joint's integrity over time.

Versatility in Design and Production

Brazing offers a level of flexibility in both material choice and assembly design that is difficult to match with other joining methods.

Joining Dissimilar Materials

One of brazing's most significant advantages is its ability to join vastly different materials. Metals can be joined to other metals, non-metals, or ceramics.

Because the base materials are not melted, issues of metallurgical incompatibility that plague fusion welding are avoided, opening up a world of design possibilities.

Enabling Complex Assemblies

Brazing allows for the creation of intricate and delicate assemblies that would be impossible to weld. Multiple joints on a single complex part can be brazed simultaneously in one furnace cycle.

This capability makes it an ideal process for high-volume production of components like heat exchangers, turbine blades, and electronic assemblies.

Key Considerations and Limitations

While powerful, brazing is not a universal solution. Understanding its operational requirements is critical for success.

The Need for Tight Tolerances

Capillary action, the driving force of brazing, requires a precise, narrow gap between the parts being joined. This often necessitates higher precision in the manufacturing of individual components compared to welding.

Surface Cleanliness is Paramount

For a strong metallurgical bond to form, the surfaces of the joint must be exceptionally clean. Any oils, grease, or oxides will prevent the filler metal from properly wetting and adhering to the base materials.

Lower Temperature Resistance

The service temperature of a brazed component is limited by the melting point of the filler metal, not the base materials. For high-temperature applications, the choice of filler alloy is a critical design constraint.

Making the Right Choice for Your Goal

Selecting brazing depends entirely on your project's specific priorities.

- If your primary focus is maximum joint integrity and cleanliness for critical applications (e.g., aerospace, medical): Vacuum brazing is the ideal choice, as it produces flux-free joints of the highest possible quality.

- If your primary focus is high-volume production of complex parts with many joints: Controlled atmosphere furnace brazing excels, allowing for hundreds or thousands of joints to be made in a single, repeatable cycle.

- If your primary focus is joining dissimilar materials like copper to steel or metal to ceramic: Brazing is one of the most effective and reliable methods available, as it avoids the metallurgical problems of fusion welding.

- If your primary focus is minimizing distortion in a high-precision assembly: Brazing's low, uniform heating provides unparalleled dimensional stability compared to the intense, localized heat of welding.

Ultimately, brazing empowers engineers to create strong, clean, and complex assemblies while preserving the fundamental properties of the materials they are joining.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Strong, Clean Joints | Metallurgical bond often stronger than base metals |

| Joins Dissimilar Materials | Metals, ceramics, and more without metallurgical issues |

| Preserves Base Metal Integrity | Low heat prevents changes to material properties |

| Complex Assemblies | Multiple joints can be made simultaneously |

| Reduced Stress & Distortion | Uniform heating minimizes warping and residual stress |

Ready to leverage the advantages of brazing for your laboratory or production needs? KINTEK specializes in the advanced furnace systems and consumables required for precise, high-quality brazing processes. Whether you are joining dissimilar materials for R&D or require a reliable solution for high-volume production, our expertise ensures superior results. Contact us today to discuss how our brazing solutions can enhance your project's integrity and efficiency.

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- How do you make an inert atmosphere? Master Safe, Pure Processes with Inerting

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes