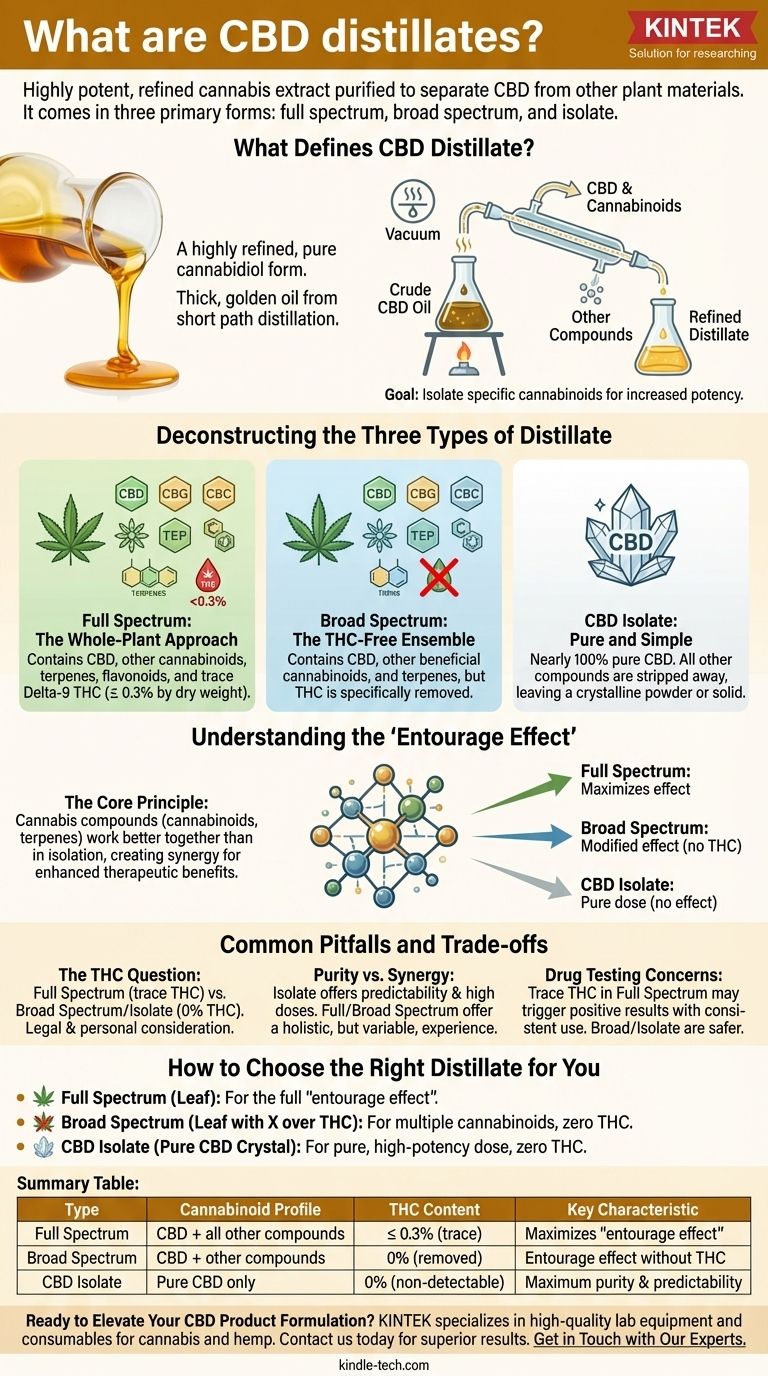

In short, CBD distillate is a highly potent, refined cannabis extract that has been purified to separate the CBD compound from other plant materials. It comes in three primary forms: full spectrum (containing all plant compounds, including trace THC), broad spectrum (with THC removed), and isolate (pure CBD with nothing else).

The fundamental difference between CBD distillates lies in their chemical profile. Your choice depends on a single question: do you want the synergistic "entourage effect" from multiple plant compounds, and are you comfortable with trace amounts of THC?

What Defines CBD Distillate?

CBD distillate is one of the purest forms of cannabidiol available. It's a thick, viscous oil, often amber or gold in color, that has undergone a specific purification process.

A Highly Refined Extract

The creation of distillate involves heating crude CBD oil under a vacuum. This process, known as short path distillation, separates compounds based on their different boiling points.

The goal is to isolate specific cannabinoids, primarily CBD, resulting in a product that is significantly more potent than less-refined oils or raw hemp flower.

The Base for Many Products

Distillate is rarely sold directly to consumers in its raw, sticky form. Instead, it serves as the foundational ingredient for a vast array of common CBD products, including tinctures, vape cartridges, edibles, and topicals.

Deconstructing the Three Types of Distillate

The terms "full spectrum," "broad spectrum," and "isolate" describe which compounds remain in the final distillate after processing. This is the most critical factor in determining the product's effects.

Full Spectrum: The Whole-Plant Approach

Full spectrum distillate contains CBD alongside all the other cannabinoids, terpenes (aromatic compounds), and flavonoids that were present in the original hemp plant.

This includes trace amounts of Delta-9 THC, the psychoactive compound in cannabis. By federal law in the U.S., this amount must not exceed 0.3% by dry weight.

Broad Spectrum: The THC-Free Ensemble

Broad spectrum distillate is the middle ground. It contains CBD and a range of other beneficial cannabinoids and terpenes but has undergone an additional refinement process to specifically remove the THC.

This type is designed for those who want the potential benefits of multiple plant compounds working together without consuming any THC.

CBD Isolate: Pure and Simple

CBD isolate is the most refined form, often referred to as THC-free or THC-ND (non-detectable). It is nearly 100% pure CBD.

During its processing, all other cannabinoids, terpenes, and plant compounds are stripped away, leaving behind a crystalline powder or solid that can be mixed into products.

Understanding the "Entourage Effect"

The key reason for the different distillate types is a theory known as the entourage effect.

The Core Principle

This theory suggests that cannabis compounds, including cannabinoids like CBD and THC and aromatic terpenes, work better together than they do in isolation.

The presence of multiple compounds is believed to create a synergy that can enhance the potential therapeutic benefits and modulate the effects of any single compound.

Why It Matters for Your Choice

Full spectrum products are formulated to maximize this effect. Broad spectrum aims to provide a modified version of it without THC. CBD isolate forgoes the entourage effect entirely in favor of delivering a pure, targeted dose of CBD.

Common Pitfalls and Trade-offs

Choosing a distillate type involves balancing benefits against potential drawbacks, primarily centered around THC.

The THC Question

The main trade-off is clear: the potential for a more robust entourage effect with full spectrum versus the absolute certainty of avoiding THC with broad spectrum or isolate. This is a critical consideration for legal, professional, or personal reasons.

Purity vs. Synergy

Isolate offers predictability and the ability to consume high, precise doses of CBD without interference from other compounds. Full and broad spectrum products offer a more complex, holistic profile that some users find more effective, but the experience can be more variable.

Drug Testing Concerns

It is important to note that the trace amounts of THC in full spectrum products can, with consistent and high-dose use, potentially accumulate in the body and trigger a positive result on a sensitive drug screening. For those subject to testing, broad spectrum or isolate are the safer choices.

How to Choose the Right Distillate for You

Your selection should be guided by your personal health goals and your tolerance or preference regarding THC.

- If your primary focus is experiencing the full "entourage effect": Choose a full spectrum product to benefit from the complete range of plant compounds working in synergy.

- If your primary focus is benefiting from multiple cannabinoids while completely avoiding THC: Choose a broad spectrum product for a balanced profile without THC exposure.

- If your primary focus is a pure, high-potency dose of CBD with zero THC or other compounds: Choose a CBD isolate product for maximum purity and predictability.

Ultimately, understanding the distinct purpose of each distillate type empowers you to make an informed decision aligned with your wellness objectives.

Summary Table:

| Type | Cannabinoid Profile | THC Content | Key Characteristic |

|---|---|---|---|

| Full Spectrum | CBD + all other plant compounds (cannabinoids, terpenes) | ≤ 0.3% (trace amounts) | Maximizes the "entourage effect" |

| Broad Spectrum | CBD + other cannabinoids & terpenes | 0% (removed) | Entourage effect without THC |

| CBD Isolate | Pure CBD only | 0% (non-detectable) | Maximum purity and predictability |

Ready to Elevate Your CBD Product Formulation?

As a laboratory professional or manufacturer, the purity and consistency of your CBD distillates are critical to your product's success. KINTEK specializes in providing high-quality lab equipment and consumables tailored to the cannabis and hemp industry.

Our precision distillation systems and analytical tools ensure you can produce and verify the quality of full spectrum, broad spectrum, and isolate products with confidence. Whether you're scaling up production or requiring exacting purity standards, we have the solutions to support your workflow.

Contact us today to discuss how our equipment can help you achieve superior results in your CBD extraction and refinement processes.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Gold Plating Tungsten Molybdenum Crucible for Evaporation

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the target substrate distance for sputtering? Optimize Your Thin Film Deposition Process

- What are some disadvantages of powder metallurgy? Size, Strength, and Complexity Limitations

- What is the purpose of post-deposition heat treatment at 700°C for Al coatings? Enhance Oxidation Resistance

- What is the function of a laboratory vacuum system in preparing COF precursors? Ensure Purity & Prevent Oxidation

- Can you separate the solid and liquid in a solution by filtering? No, and Here's Why

- How do you evaporate DMSO solvent? Master Gentle, High-Vacuum Techniques for Sensitive Samples

- What is the correct shutdown and disassembly procedure after an experiment? Ensure Safety and Protect Your Equipment

- What temperature is glass sintering? Master the Precise Thermal Window for Your Glass