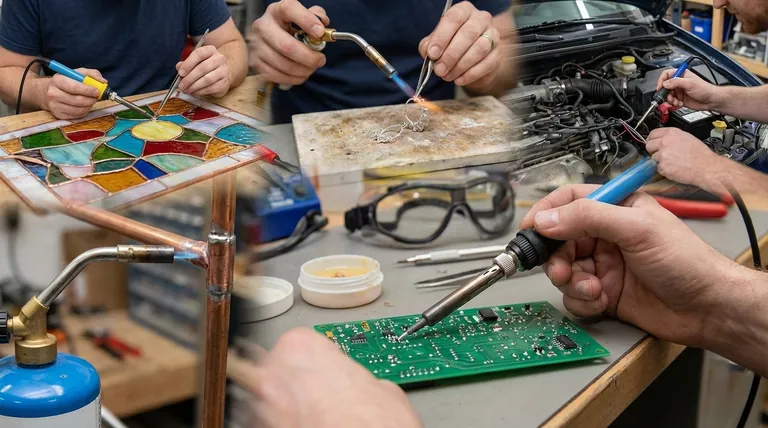

At its core, soldering is a fundamental process for joining materials, with applications reaching far beyond the electronics workbench. Its five most common applications include assembling printed circuit boards (PCBs), joining copper pipes in plumbing, crafting jewelry, creating stained glass art, and performing automotive repairs. Each of these fields leverages soldering for its unique ability to create a strong, conductive, or sealed joint without melting the base materials.

Soldering is not a single technique but a versatile joining method. Its true value is understood by seeing how its tools, materials, and purpose are adapted to meet the distinct demands of vastly different industries—from microelectronics to construction and art.

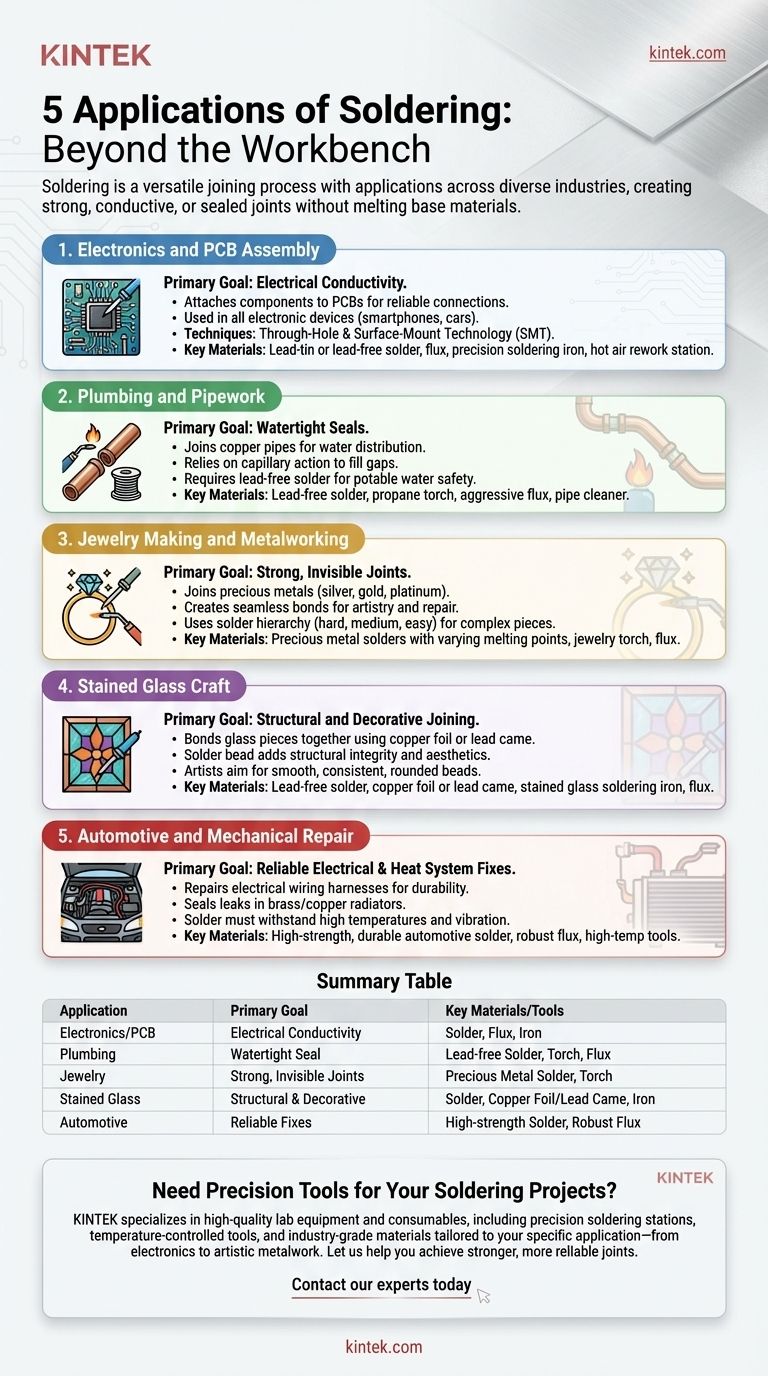

1. Electronics and Printed Circuit Board (PCB) Assembly

The Backbone of Modern Devices

Soldering is the primary method used to attach electronic components to a PCB. This process creates a secure physical bond and, more importantly, a reliable electrical connection that allows the circuit to function.

Every complex electronic device, from your smartphone to your car's engine control unit, relies on millions of precise solder joints to operate correctly.

Through-Hole vs. Surface-Mount Technology

In through-hole soldering, component leads are inserted through holes in the PCB and soldered on the opposite side. This creates a very strong mechanical bond.

Surface-mount technology (SMT) is more common today, where components are placed directly onto pads on the board's surface and soldered in place. SMT allows for much greater component density and is essential for miniaturization.

2. Plumbing and Pipework

Creating Watertight Seals

In plumbing, soldering (often called "sweating" a pipe) is used to join copper pipes and fittings. A propane torch heats the joint, and solder is melted into the gap, creating a permanent, watertight seal.

This application relies on capillary action, where the molten solder is drawn into the tight space between the pipe and the fitting.

Material and Safety Considerations

Plumbing solder is fundamentally different from electronics solder. It must be lead-free by law for any application involving potable water to prevent contamination.

The flux used is also much more aggressive to clean the oxidation from the copper pipes, ensuring the solder bonds correctly.

3. Jewelry Making and Metalworking

Artistry and Precision

Jewelers use soldering to join pieces of precious metal like silver, gold, and platinum. This process is essential for creating rings, setting stones in bezels, and repairing broken chains.

Unlike electronics, the goal here is often to create a joint that is both strong and invisible, blending seamlessly with the original piece.

A Hierarchy of Solders

For complex pieces, jewelers use solders with different melting points, often categorized as hard, medium, and easy.

They begin with hard solder (highest melting point) for the first joint. For subsequent joints on the same piece, they use a solder with a lower melting point to avoid melting the previous work.

4. Stained Glass Craft

Structural and Decorative Joining

Soldering is the critical step that holds a stained glass panel together. After pieces of glass are wrapped in copper foil or fitted into lead came, solder is applied to all the seams.

The solder joins the metal strips, forming a rigid matrix that provides the artwork with its structure and strength.

The "Bead" of Solder

In stained glass, the appearance of the solder line, or "bead," is part of the aesthetic. Artists strive for a smooth, consistent, and rounded bead that complements the design of the glass. The solder is both functional and a key decorative element.

5. Automotive and Mechanical Repair

Repairing Electrical and Heat Systems

In the automotive world, soldering is crucial for repairing electrical wiring harnesses. It provides a more reliable and corrosion-resistant connection than simple crimping, especially in environments with high vibration.

It is also used to repair leaks in older brass and copper radiators, where solder seals the joints between the core tubes and fins.

High-Temperature Demands

The solders used in automotive applications must be robust enough to withstand constant vibration and significant temperature swings without failing. This requires alloys that are stronger and more durable than typical electronics solder.

Understanding the Trade-offs

Strength Limitations

A solder joint is significantly weaker than the base metals it joins. For high-stress, load-bearing structural applications, processes like welding or brazing, which occur at much higher temperatures, are required.

Temperature Sensitivity

Because solder has a relatively low melting point, it is unsuitable for high-temperature environments. The joint will lose its strength and ultimately fail if its operating temperature approaches the solder's melting point.

Material Compatibility

Soldering is not a universal solution for joining all metals. It works exceptionally well on copper, silver, tin, and gold but requires special fluxes and techniques for metals like aluminum or stainless steel, which form tough oxide layers that prevent bonding.

Making the Right Choice for Your Goal

- If your primary focus is electrical conductivity: Soldering is the industry standard for creating durable and reliable connections on circuit boards.

- If your primary focus is creating a watertight seal: Soldering copper pipes is a proven and permanent method, provided you use the correct lead-free materials for plumbing.

- If your primary focus is joining structural parts under high stress: You should look to welding or brazing, as soldering will not provide the necessary mechanical strength.

- If your primary focus is artistic metalwork: Soldering offers unmatched precision for detailed work in jewelry and stained glass where strength is secondary to form.

Understanding these distinct applications is the key to mastering the art and science of soldering for any project.

Summary Table:

| Application | Primary Goal | Key Materials/Tools |

|---|---|---|

| Electronics/PCB Assembly | Electrical Conductivity | Lead-tin solder, flux, soldering iron |

| Plumbing & Pipework | Watertight Seal | Lead-free solder, propane torch, flux |

| Jewelry Making | Strong, Invisible Joints | Precious metal solder, torch, different melting points |

| Stained Glass Craft | Structural & Decorative Joining | Lead-free solder, copper foil/lead came, soldering iron |

| Automotive Repair | Reliable Electrical/Heat System Fixes | High-strength solder, robust flux, high-temp tools |

Need Precision Tools for Your Soldering Projects?

Whether you're assembling complex PCBs, crafting intricate jewelry, or performing delicate repairs, the right equipment is crucial for flawless results. KINTEK specializes in high-quality lab equipment and consumables, including precision soldering stations, temperature-controlled tools, and industry-grade materials tailored to your specific application—from electronics to artistic metalwork.

Let us help you achieve stronger, more reliable joints. Contact our experts today to discuss your soldering needs and discover how KINTEK's solutions can enhance your workflow and outcomes.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Vacuum Heat Treat Sintering Brazing Furnace

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- Gold Electrochemical Sheet Electrode Gold Electrode

People Also Ask

- Why are high-precision vacuum sintering furnaces preferred over traditional methods for biofunctional dental ceramics?

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- What is the function of a porcelain furnace? Precision Firing for Lifelike Dental Restorations

- Why is a 1000°C+ furnace needed for LLZO/LLTO? Mastering High-Temperature Sintering for Ceramic Electrolytes

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development