From a technical standpoint, pyrolysis presents a powerful set of advantages centered on converting low-value organic waste into high-value products. It simultaneously addresses waste reduction, creates alternative energy sources, and enables the recovery of valuable materials, making it a highly flexible and efficient thermochemical process.

The core advantage of pyrolysis is not just waste destruction, but waste transformation. It unlocks the chemical and energy value stored in materials like biomass, plastics, and tires, converting an environmental liability into a tangible economic asset.

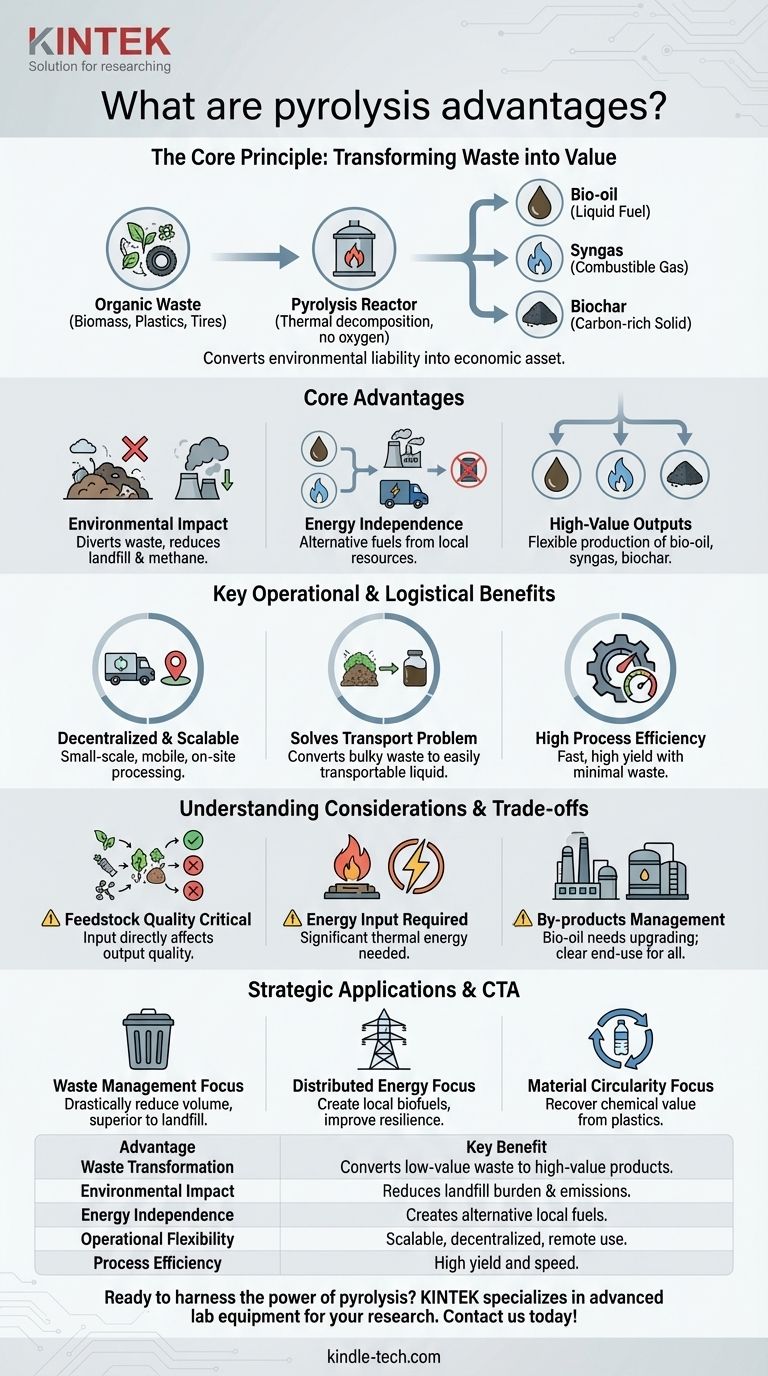

The Core Principle: Transforming Waste into Value

Pyrolysis is a process of thermal decomposition in the absence of oxygen. This controlled heating breaks down complex organic materials into simpler, more valuable outputs, fundamentally changing how we view waste streams.

Reducing Landfill and Environmental Burden

Pyrolysis directly diverts significant volumes of organic waste from landfills. This includes agricultural residues, wood waste, and end-of-life plastics and rubber.

By processing these materials, it mitigates the environmental impact of landfilling, such as methane emissions and soil contamination, while reducing the need to extract virgin raw materials.

Creating High-Value Outputs

The process is uniquely flexible, producing three distinct types of valuable products from a single feedstock.

The primary outputs are bio-oil (a liquid fuel), syngas (a combustible gas mixture), and biochar (a stable, carbon-rich solid). The specific yield of each depends on the process conditions.

A Pathway to Energy Independence

The liquid and gas products serve as direct alternatives to fossil fuels. Bio-oil can be refined into transportation fuels or used for heat and power generation.

This creates a pathway for producing energy from local, often discarded, resources, enhancing energy security and reducing reliance on traditional fossil fuels.

Key Operational and Logistical Advantages

Beyond its chemical outputs, pyrolysis offers significant practical benefits that make it an attractive technology for distributed applications.

Decentralized and Scalable Operations

Pyrolysis facilities can be built on a relatively small, even mobile, scale. This is a critical advantage for processing waste in remote locations or directly at the source.

This scalability avoids the massive capital investment required for traditional, centralized refineries and allows for more targeted, community-level solutions.

Solving the Biomass Transport Problem

Raw biomass is often bulky, wet, and difficult to transport efficiently. Pyrolysis solves this by converting it into energy-dense liquid bio-oil.

This liquid is far cheaper and easier to store and transport to a central facility for upgrading or use, dramatically improving the logistics of waste-to-energy systems.

High Process Efficiency

Modern pyrolysis methods, particularly fast and flash pyrolysis, are engineered for speed and high yield.

These processes can convert nearly all of the incoming feedstock into usable products with minimal waste. The reactors are relatively simple, and the technology has reached a level of commercial maturity.

Understanding the Trade-offs and Considerations

While powerful, pyrolysis is not a universal solution. An objective assessment requires understanding its operational requirements and limitations.

Feedstock Quality is Critical

The quality and consistency of the input material (feedstock) directly determine the quality and composition of the output products. Contaminants can impact the final product and the efficiency of the process.

Energy Input Requirements

Pyrolysis is not a "free" energy source. The process itself requires a significant thermal energy input to heat the feedstock to the required temperatures. An efficient system often uses a portion of its own output (syngas) to power the process.

By-products Require Management

The primary outputs, especially bio-oil, often require further upgrading or refining before they can be used as a drop-in replacement for conventional fuels. Biochar and syngas must also have a clear end-use to make the overall process economically viable.

Responsible Implementation is Key

To realize the environmental benefits, pyrolysis plants must be operated responsibly with proper controls. This ensures that the process itself does not create unintended emissions or environmental impacts.

Making the Right Choice for Your Goal

The advantages of pyrolysis are best applied when aligned with a specific strategic objective.

- If your primary focus is waste management: Pyrolysis offers a superior alternative to landfilling by drastically reducing waste volume and converting it into stable, valuable outputs.

- If your primary focus is distributed energy production: Its scalability allows for the creation of local biofuels from regional waste, reducing transportation costs and improving energy resilience.

- If your primary focus is material circularity: The process is exceptionally effective at recovering the chemical value from waste plastics and rubber, creating feedstock for new materials.

Ultimately, pyrolysis serves as a critical technological bridge, enabling a more sustainable and circular approach to managing our material and energy resources.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Waste Transformation | Converts low-value organic waste into high-value products (bio-oil, syngas, biochar). |

| Environmental Impact | Reduces landfill burden and methane emissions by diverting waste streams. |

| Energy Independence | Creates alternative fuels (bio-oil, syngas) from local resources, reducing fossil fuel reliance. |

| Operational Flexibility | Scalable, decentralized technology suitable for remote or community-level applications. |

| Process Efficiency | Modern methods like fast pyrolysis offer high yield and speed with minimal waste. |

Ready to harness the power of pyrolysis for your lab or waste management needs?

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're processing biomass, plastics, or other materials, our solutions help you achieve precise thermal decomposition and maximize product yield.

Contact us today to discuss how our expertise can support your pyrolysis projects and drive your sustainability goals forward. Get in touch via our contact form to learn more!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success