At its core, a sieve shaker is a laboratory instrument used to perform particle size analysis on granular or powdered materials. It automates the process of agitating a stack of test sieves, ensuring that particles are efficiently and accurately sorted by size. This allows for precise measurement of a material's particle size distribution, which is a critical quality parameter across countless industries.

The fundamental purpose of a sieve shaker is to replace inconsistent manual sieving with a mechanical process that delivers highly repeatable and accurate results. It standardizes the method of particle separation, which is essential for quality control, research, and production.

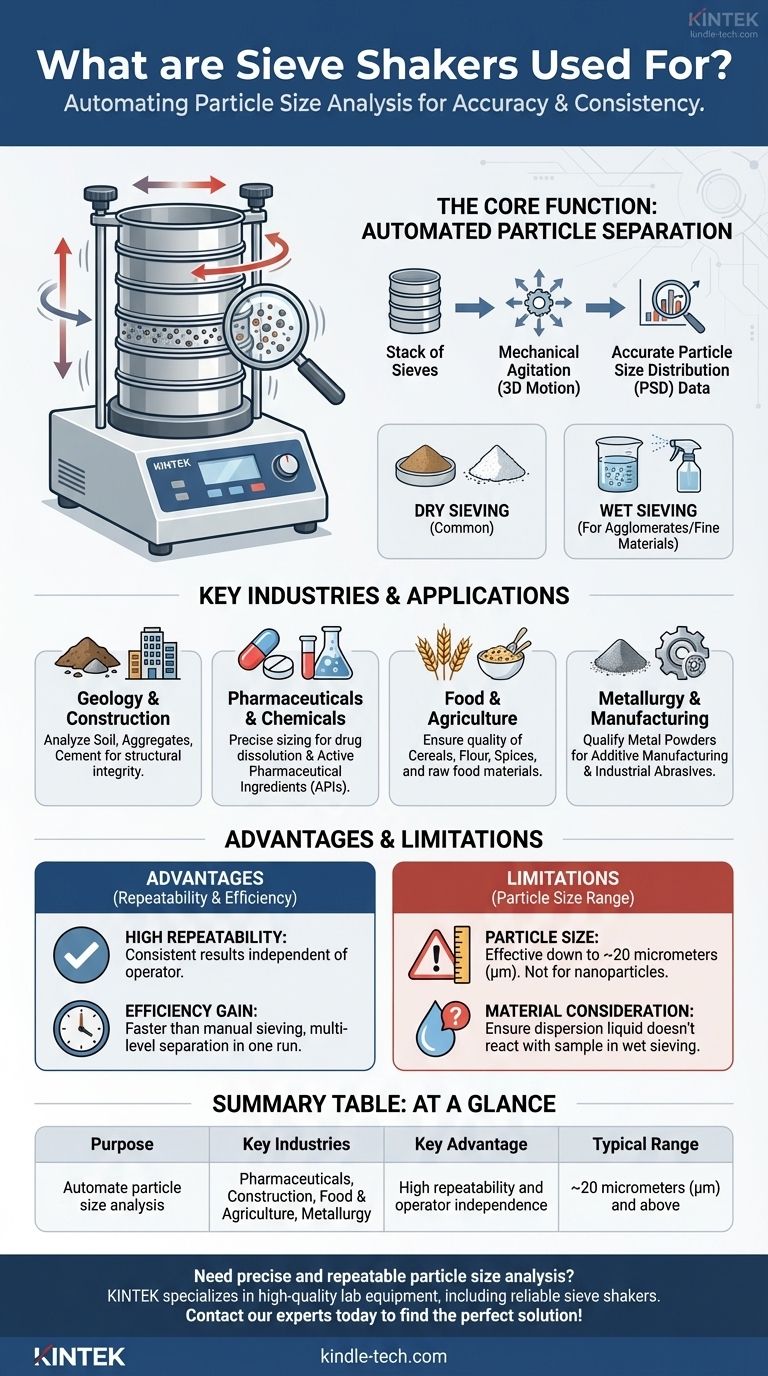

The Core Function: Standardizing Particle Separation

A sieve shaker’s primary role is to bring mechanical consistency to the age-old process of sieving. By controlling the agitation, it removes the variability inherent in manual methods.

How It Works

A sieve shaker imparts a specific, consistent motion to a stack of sieves. This is often a 3-D throwing motion that combines a horizontal circular movement with a vertical tapping motion. This ensures particles are lifted off the sieve mesh and reoriented, giving them the maximum opportunity to pass through the apertures.

Wet vs. Dry Sieving

Sieve shakers are versatile and can be used for both dry sieving, the most common method, and wet sieving. Wet sieving is necessary for materials that tend to agglomerate or are very fine, using a liquid (typically water) to help disperse the particles and prevent the mesh from blinding.

From Raw Material to Final Product

This analysis is not just a research activity. It is used at every stage of production, from inspecting incoming raw materials to ensuring the quality of final products before they are shipped.

Where Are Sieve Shakers Used? A Look at Key Industries

The need to characterize particle size is nearly universal in material-based industries. Sieve shakers are the workhorse instruments for this task.

Geology and Construction

In these fields, particle size dictates material behavior. Sieve shakers are used to analyze soil, aggregates for paving roads, and the sand and cement used in construction mortar to ensure structural integrity and performance.

Pharmaceuticals and Chemicals

The pharmaceutical industry relies on precise particle sizing to control drug dissolution rates and bioavailability. Sieve shakers are used to test active ingredients and excipients according to strict pharmacopoeia standards.

Food and Agriculture

Particle size affects the texture, mouthfeel, and processing behavior of food products. Shakers are used for quality assessments of cereals, grains, flour, spices, and other raw food materials.

Metallurgy and Manufacturing

From metal powders for additive manufacturing to industrial abrasives, controlling particle size is essential for performance. Sieve shakers are used to qualify raw carbon materials, minerals, and other granular industrial products.

Understanding the Advantages and Trade-offs

While incredibly useful, it's important to understand where sieve shakers excel and what their practical limitations are.

The Primary Advantage: Repeatability

The single greatest benefit of a sieve shaker is repeatability. By using a defined shaking amplitude and time, you ensure that a sample tested today will yield the same results as the same sample tested a month from now, regardless of the operator. This is the foundation of a reliable quality control program.

The Efficiency Gain

A sieve shaker is significantly faster than manual sieving and allows a technician to perform other tasks while the analysis runs. Furthermore, it enables the use of a multi-level stack of sieves, allowing for the separation of a sample into many size fractions in a single run.

The Practical Limitation: Particle Size

Sieve shakers are highly effective for coarse materials down to fine powders, typically in the range of several inches down to about 20 micrometers (μm). Below this threshold, physical sieving becomes impractical. For finer nanoparticles or sub-micron materials, alternative methods like laser diffraction are required.

The Material Consideration

When performing wet sieving, you must ensure the liquid used for dispersion does not adversely affect the material. The goal is only to separate the particles, not to dissolve or react with them.

Making the Right Choice for Your Goal

To determine if a sieve shaker is the right tool, consider the objective of your analysis.

- If your primary focus is routine quality control for granular materials: A sieve shaker is the industry-standard instrument for achieving reliable, operator-independent results.

- If your primary focus is high-volume testing of powders or aggregates: The speed and automation of a sieve shaker provide a clear and rapid return on investment over manual methods.

- If your primary focus is characterizing materials smaller than 20 microns: You should investigate particle analysis methods designed for finer ranges, such as laser diffraction or dynamic light scattering.

Ultimately, mastering particle size analysis begins with using the right tool for the job, and the sieve shaker remains the definitive instrument for repeatable mechanical sieving.

Summary Table:

| Purpose | Key Industries | Key Advantage | Typical Range |

|---|---|---|---|

| Automate particle size analysis | Pharmaceuticals, Construction, Food & Agriculture, Metallurgy | High repeatability and operator independence | ~20 micrometers (μm) and above |

Need precise and repeatable particle size analysis for your laboratory? KINTEK specializes in high-quality lab equipment and consumables, including reliable sieve shakers designed to meet rigorous quality control standards. Whether you're in pharmaceuticals, construction, or food production, our solutions help you ensure product consistency and performance. Contact our experts today to find the perfect sieve shaker for your application!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Oscillating Orbital Shaker

People Also Ask

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research